In the context of climate change is becoming a global threat, greenhouse gas inventory (GHG Inventory) emerged as a solution strategy for the organization and the business. This is not only a measurement tool, emission, which is also the first step for the route to minimize environmental impact, optimize production efficiency and meet international standards.

The inventory will help the business identify and control the source of emissions, create conditions to participate in the program credit carbon exchange system emissions, the strategy for sustainable development. In this article Lac Viet Computing will help you understand more about the process on greenhouse gas inventory, tools, support, benefits, practices, thereby building a production system, operational efficiency, friendly to the environment.

1. Greenhouse gas inventory is what?

1.1. Definition

Greenhouse gas inventory (GHG Inventory) is a process of measuring, calculating and reporting of greenhouse gas emissions from the operation of an organization, business, or product in a certain period of time. This is important tool to help businesses effectively manage emissions to meet international standards and develop strategies to minimize greenhouse gas.

The main components:

- Measurement: Collects data on the sources of greenhouse gas emissions directly and indirectly.

- Calculation: Apply emission factors suitable to calculate the amount of greenhouse gas emissions.

- Report: Synthesis and presents results of emissions in each scope (Scope 1, 2, 3) in a transparency report, in detail.

1.2. The greenhouse gases are inventory

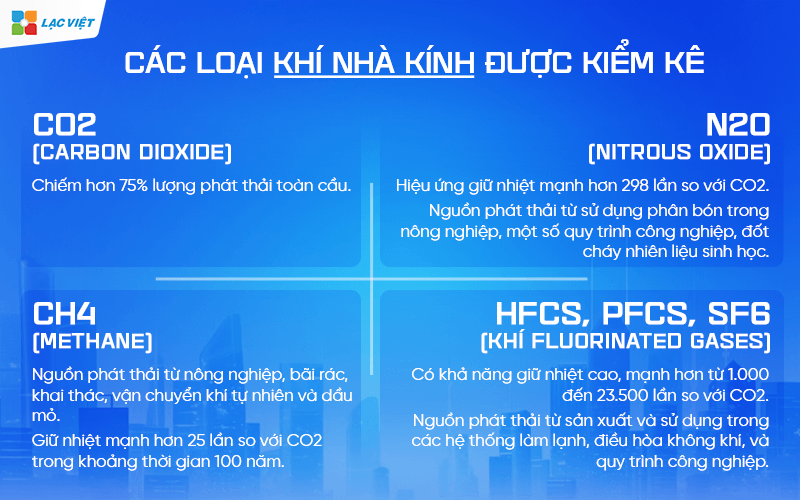

Under the provisions of IPCC (The intergovernmental panel on Climate change), the greenhouse gases that are inventoried include:

- CO2 (Carbon dioxide): Greenhouse gases are the most common, accounting for more than 75% of global emissions. Emission source: Burning fossil fuels (coal, oil, natural gas), cement production, burning forest.

- CH4 (Methane): Have the ability to retain heat more than 25 times greater than CO2 in a 100 year period. Emission source: Agricultural (livestock), landfill, mining and transportation of natural gas.

- N2O (Nitrous oxide): Effect retains heat more powerful 298 times higher than CO2. Emission source: fertilizer Use in agriculture, a number of industrial processes, combustion of biofuels.

- Gas fluorinated gases (HFCs, PFCs, SF6): Have the ability to hold high heat, more power from 1,000 to 23.500 times higher than CO2. Emission source: Production and use in the cooling system, air conditioning, industrial processes.

2. Why greenhouse gas inventory important?

2.1 Meet international standards

Greenhouse gas inventory is the first step to business in compliance with the international standards such as GHG Protocol or ISO 14064. This is also the basis for participation in the program credit only carbon and emissions as The EU Emission Trading Scheme (EU ETS).

Practical example: The manufacturing enterprises in Europe have to make a greenhouse gas inventory to meet the regulations of the EU ETS and reduce the cost of buying credits carbon.

2.2 effective Management operation

Greenhouse gas inventory helps businesses to clearly define the source of emissions, the largest of its activities, from which optimize the production process and minimize wasted energy.

Practical example: A plant cement production, after the inventory realize that the system furnaces up to 50% CO2 emissions and decided to invest in technology to reduce emissions, modern, helps save costs, reduce emissions significantly.

2.3 Increase the reputation and brand value

Business made greenhouse gas inventory is often more appreciated by partners, investors and customers. Committed to transparency in greenhouse gas emissions helps to improve brand image, creating competitive advantages on the international market.

Specific benefits: Attract investors interested in the criteria for ESG (Environmental, Social and Governance). Increase sales from customer preferred products friendly with environment.

2.4. Contribute to the sustainable development goals

Greenhouse gas inventory is an important step in the roadmap towards developing sustainable and carbon neutral. This not only helps minimize the impact climate change, but also contribute to the objective of global climate as The agreement Paris.

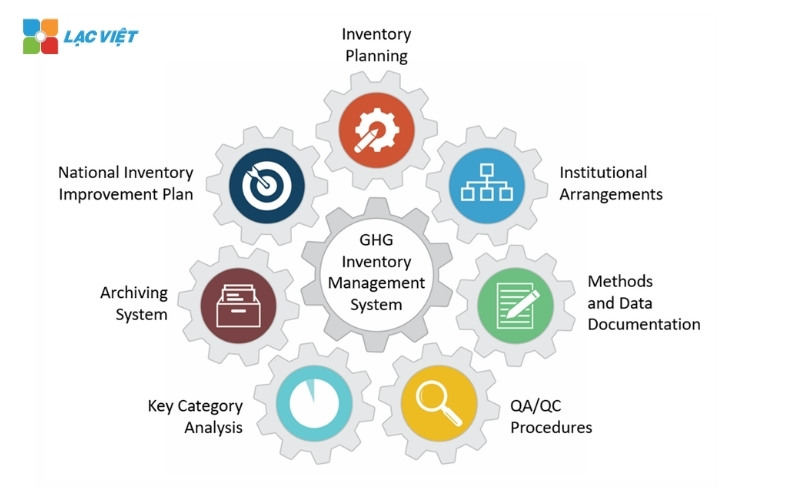

3. Process greenhouse gas inventory

Process greenhouse gas inventory is an important step for businesses to measure and manage emissions, thereby building strategy to reduce and meet the international standards. The implementation of this process help businesses reduce operating costs, contributing to environmental protection and enhancing brand reputation.

Step 1. Determine the range of emissions (Scopes)

Determine the range of emissions is the first step and the most important in-process inventory. This helps businesses to understand the amount of greenhouse gas emissions come from anywhere and divided them into three main areas:

Scope 1 – direct emission or: Is the amount of greenhouse gas emissions from sources that business directly control, including:

- Means of transport owned by: Trucks, cars, or equipment powered by fossil fuels.

- Boiler and production equipment: Use of fossil fuels such as coal, oil, or natural gas.

- Industrial processes: The operation produced such as chemicals, cement, or steel.

Scope 2 – emissions indirectly from energy: Emissions from the consumption of electricity, heat, or steam purchased from outside. Although businesses do not direct emissions, but these emissions are calculated from the energy source they use.

For example: A business use to 500,000 kWh of electricity from the national grid. With the emission is 0.5 kg CO2/kWh emissions Scope 2 will be 250 tons of CO2.

Scope 3 – emissions indirectly other: Cover the entire emissions indirectly else in the supply chain, such as:

- Shipping of goods and raw materials.

- Waste and product end of life.

- Operation of the supplier.

For example: A manufacturing company needs to transport 1,000 tons of raw materials through a distance of 300 km. With the emission 0.25 kg CO2/ton/km, emissions will be 75 tons of CO2.

Step 2. Collects data emissions

After determining the scope of emissions, businesses need to collect enough data to ensure accuracy in inventory.

Data source:

- Energy bills (electricity, heat, fuel).

- Report production and operating equipment.

- Data on transportation, waste disposal and related activities in the supply chain.

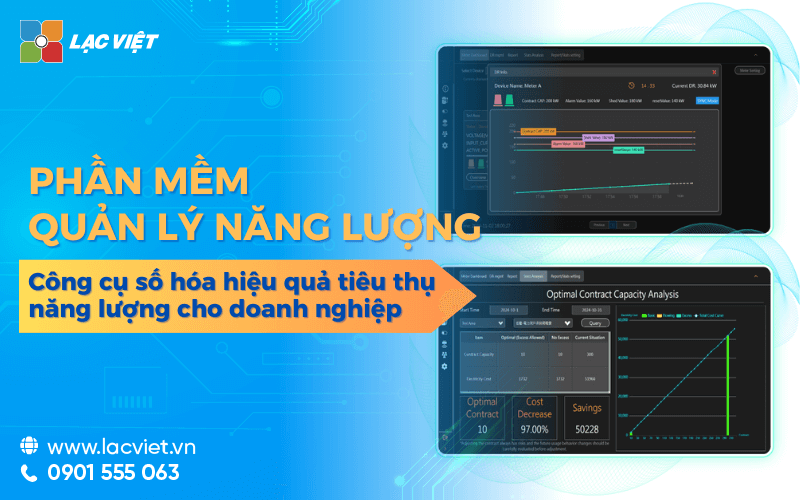

Tools of data collection:

- Use the software measurement or monitoring tool automatically.

- Cooperation with providers and partners to collect data Scope 3.

Practical example: A plant noted that the system boilers consumed 1,000 tons of coal/year, while the HVAC system consumption of 200,000 kWh of electricity/year.

Step 3. Apply the emission

The emission is only important number to convert activity data (fuel, power consumption, etc.) of the amount of greenhouse gas emissions.

References:

- Emission factors from the IPCC, GHG Protocol, or the recognized organization.

- For example: coefficient of CO2 emissions for petroleum diesel is 2,63 kg CO2/liter.

How to apply:

- Formula: Greenhouse gas emissions=Activity×coefficient of emission

- For example: A business consumption 500 liters of diesel. With the emission 2,63 kg CO2/liter, the amount of emissions will be: 500 liters ×2,63 kg CO2/liter =1.315 kg CO2

Step 4. Calculating emissions

After applying the emission, business aggregate emissions from each source and each range to take out the results of inventory overall.

Steps taken:

- Summing up the results according to each range emissions (Scope 1, 2, 3).

- Comparing with real data to ensure accuracy and consistency.

For example:

- Scope 1: 300 tons of CO2 from the boiler and car transportation.

- Scope 2: 250 tons of CO2 from power consumption.

- Scope 3: 150 tons of CO2 from transportation of raw materials.

Total emissions: 700 tons of CO2.

Step 5. Reporting greenhouse gas inventory

Report greenhouse gas inventory is an important document for business presents the results of inventory, given the solution to reduce emissions and set a plan of action.

Main content:

- Summary the total amount of greenhouse gas emissions under each scope (Scope 1, 2, 3).

- Reviews the emission source privacy and the potential for reducing emissions.

- Make recommendations for improvement as alternative technologies, use of renewable energy, or optimize the supply chain.

Standard reports:

- Compliance with international standards such as the GHG Protocol or ISO 14064.

- Reports need transparent, detailed and easy to understand to meet the requirements of the regulatory authorities or partners.

Practical example: A manufacturing company in Vietnam after reports discovered that the system boiler energy consumption the most, accounting 40% of the total emissions. The report recommends improvements in boiler technology to reduce emissions at 25% in 3 years.

4. The tools and standards support the implementation

4.1. GHG Protocol

GHG Protocol is one of the tools that are most commonly used to measure and report greenhouse gas emissions. Here is a detailed guide to help businesses understand emission sources and ways of calculation.

The main function of the GHG Protocol:

- Measuring greenhouse gas emissions from production activities, operation and supply chain.

- Provide methodological clarity to classify emission of Scope 1, Scope 2, Scope 3.

- Support construction emissions reporting transparent and easy to understand.

Benefits:

- To help businesses comply with the international standards and increase reliability in reported emissions.

- Is the basis for enterprises to participate in the program credit only carbon and exchange system global emissions.

For example: A manufacturing enterprise in Vietnam using GHG Protocol to measure emissions from the system boiler (Scope 1) and power consumption (Scope 2). The results help them to detect the source of emissions privacy, improve the operational efficiency.

4.2. ISO 14064

ISO 14064 is the international standard of measurement, management and reporting of greenhouse gas emissions. This standard is designed for businesses to easily apply into practice and achieve the goals of sustainable development.

The main part of the ISO 14064:

- Part 1: The ultimate guide to measuring and reporting greenhouse gas emissions for the organization.

- Part 2: Provides methods to assess projects that reduce greenhouse gas emissions.

- Part 3: Given the requirements and guidance on verification, appraisal greenhouse gases.

Advantages:

- Increase transparency, accuracy of data emissions.

- Is the basis for enterprises to achieve international certification, enhance brand reputation.

For example: A transportation company applies ISO 14064 to measure the amount of CO2 gas from their car, at the same time identify measures to reduce emissions, such as conversion to electric vehicles.

4.3. Calculation tool online

The calculation tool online is a modern solution that helps business to quickly calculate the amount of greenhouse gas emissions accurately and conveniently.

- RETScreen: Tool energy analysis, comprehensive business support, project evaluation, renewable energy, energy efficiency. For example, a factory using RETScreen to evaluate the effectiveness of the system installation, solar energy, thereby reducing CO2 emissions.

- CoolClimate Calculator: Supports calculate greenhouse gas emissions for the operation of the business, from production to shipping. For example, a food company using this tool to measure emissions from the transport of raw materials and distribution of products.

5. Examples of practices on greenhouse gas inventory

5.1. Unilever: Reducing emissions in the global supply chain

Unilever, one of the leading corporations in the world of consumer products, has developed a greenhouse gas inventory across the entire supply chain, from production to distribution.

Specific action:

- Evaluation of emissions from the activities directly at the factory (Scope 1).

- Analysis of emissions from the consumption of electric energy (Scope 2).

- Determine the emissions in the supply chain such as shipping, handling product end of life (Scope 3).

Results:

- Discount 15% CO2 global emissions in the next 3 years.

- Strengthening collaboration with suppliers to reduce emissions Scope 3 through the use of renewable energy and materials, environmentally friendly.

Greenhouse gas inventory comprehensive step is important to help businesses identify points to improve and build strategic sustainability performance.

5.2. Nestlé: sustainable development through greenhouse gas inventory

Nestlé has made greenhouse gas inventory across the entire supply chain, including activities, direct and indirect, in order to meet the commitment to be carbon neutral by 2050.

Specific action:

- Measurement of emissions from factory and farm supply of raw materials.

- Apply modern technology to reduce emissions from the boiler, production lines, transportation.

Results:

- Discount millions of tons of CO2/year thanks to the optimization of production processes and use of renewable energy.

- Achieve the emission reduction 30% by 2025 compared with 2015.

Greenhouse gas inventory not only help reduce emissions but also improve operational efficiency, save energy costs.

5.3. Vietnam: The business pioneer apply greenhouse gas inventory

In Vietnam, many large enterprises have applied a greenhouse gas inventory to meet the international standards and market participants credits carbon.

- Vinamilk: Make an inventory of greenhouse gas emissions at the farm and factory. Apply system solar energy at the base, fell more than 50,000 tons of CO2/year.

- File Vietnam Oil and gas group (PVN): Inventory at the rig and oil refineries. Given the solution to reduce emissions from the optimization of production processes, using energy-efficient.

Vietnamese businesses are step by step approach international standards, reduce emissions, enhance competitiveness in the global market.

Let's get started greenhouse gas inventory today to build a production system operating sustainable, meet international standards and contributes to the common goals of humanity in reducing the impact on climate change. Greenhouse gas inventory not only is the solution, but also the responsibility, the opportunity for business to grow more sustainable future.