In the context of input costs increasing,environmental regulations become stricter, it, energy management is becoming a strategic priority in many modern businesses. Besides, conversion trends green and requirements for transparency emissions from international partners, customers or investors is increasing. Energy management not only is the content in the report, ESG, which is also clearly demonstrates a commitment to sustainable development of the enterprise.

The goal of this article Lac Viet Computing will help the business organizations:

- Properly understand the nature role of energy management

- Distinguish between savings short-term management and long-term

- Choice is the method, the suitable route with practical resources

1. Management what is energy? Understand the right to deploy the right

Energy management is the process of monitoring, control, evaluation and to optimize the use of energy resources (electricity, hot water, fuel, compressed air...) in the business aims to achieve two main goals: reduce costs and reduce emissions without affecting the efficiency of production and business.

Other than the “power save” styled dim lights or unlimited hours of use of equipment, energy management system requires the business to have:

- Understand the current state of energy use his

- Determine the area/areas are waste

- Build an action plan with specific goals

- Track, measure, adjust periodically

For example easy to understand: If energy saving, just as you turn off the air conditioning when outside, then energy management is how you plan to replace the old equipment save more, adjust the automatic mode, the appropriate hours of operation, track the cost of electricity each month to assess the effectiveness.

It is important to manage energy not require businesses to large investment right from the start, which may start from the simple steps such as collecting data, training personnel, testing equipment energy consumption...

In strategy, modern management, energy management is not just the job of the technical department which is connected elements many parts from production, operation to finance and communication in order to navigate to a business savings, responsible with the environment.

- Software energy monitoring operational efficiency and emission reduction, sustainable

- Software energy management digitized efficient energy consumption for business

- System energy management: the optimal solution cost towards sustainable development

- Everything about iso 50001 standard in energy management for modern business

2. The method of energy management business can apply

Every business has particular operating private so without a pattern, energy management uniquely suited for all. However, there are four common methods that businesses nowadays are applying from simple to in-depth. Below is analysis, detail, comes with real benefits and hints deployment.

2.1. Track manually form Excel – Solution beginning effective for small and medium enterprises

This method is suitable for the new business start deployment manager, energy or small-scale hasn conditional investment software for professional use. Business can build the form to the employee noted:

- The amount of electricity consumed by the equipment or area

- The hours of operation of machinery every day

- The cost of energy according to the monthly bill

From there, general management of data on Excel to detect anomalies, compare over time to find out the high attrition. Although handmade, this method helps form habits, energy monitoring system, is the stepping stone to move on to the more modern methods.

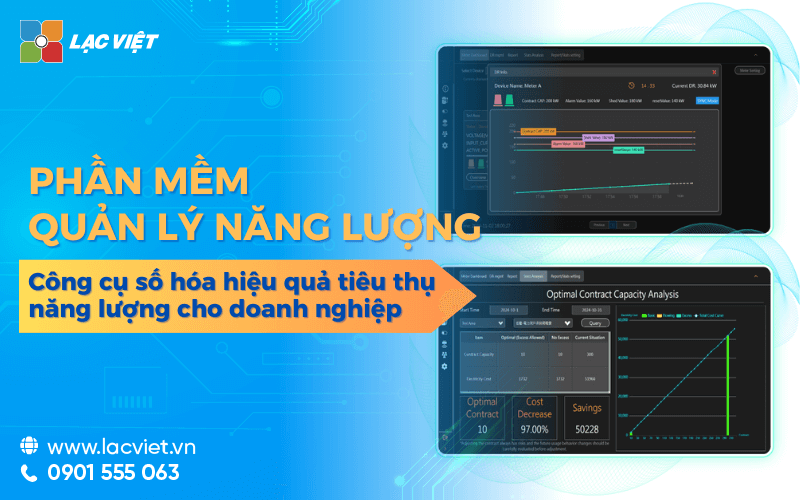

2.2. Use software energy management (EMS), in real time, increase accuracy and timely response

With the business have multiple devices large electrical power consumption, the record is not enough to control timely. Meanwhile, software deployment, energy management (Energy Management Software – EMS) will help:

- Automatically collect data from the power meter sensor

- Visual display chart of electricity consumption in real time

- Send alerts when the device works abnormally or exceeding the threshold

Exceptional benefits is to reduce dependence on human speed feedback help businesses not only “know how much to spend”, which also know “the where, when, why”.

Software EMS, particularly suitable for the manufacturing enterprises have many workshops, commercial center, office building or factory processing continuous operation.

2.3. Applicable standards ISO 50001 standard system advanced international reputation

For enterprise already has a management platform that desire to advance further in improving the efficiency, applying the standard ISO 50001 is an important step forward. This is the frame of international standards help businesses:

- Policy setting savings goals specific energy

- Risk analysis, opportunity reduction at each stage of operation

- Maintain continuous improvement system according to the PDCA cycle (plan – do – Check – Action)

Achieving ISO 50001 certification does not only bring efficiency, intrinsic, but also increase transparency, create trust for partners, customers and investors, especially in the field of export, real estate, industrial production, energy.

2.4. Integrated IoT technology and AI smart management for large-scale enterprise

With big businesses wishing to optimize deep proactive decisions quickly, the integration of IoT technology (Internet of Things) and AI (artificial intelligence) is the inevitable trend. The system will:

- Series connection of measuring devices (IoT) to collect data continuously

- Use AI to analyze consumption patterns, demand forecasting in the future

- Auto-suggest schedules optimum operating or warning risk arising

For example, a factory can apply AI to analyze historical power consumption and give suggestions adjustable shift work in order to avoid consumption at peak hours, thereby reducing costs without affecting productivity.

This solution is especially suited to businesses in the field of heavy industry, logistics, cold storage, data center, or the unit direction to model factory (Smart Factory).

Business can start from the simple method, does not need big investment, as long as there is clear commitment to reasonable route.

3. The step by step build system, energy management lessons in business

A management system energy efficiency is not formed in a day. That should be the construction plan, based on the actual operation is maintained through the steps of constant improvement. Here are 5 steps for helping businesses deploy this, whether at any scale.

Step 1. Commitment from leadership and enact energy policy

There is no management system, how successful without the consent from the head. Businesses need to start by establishing committed to saving energy, from the leaders, made clear in the text energy policy.

This policy should answer the questions:

- Business desire to achieve something in 1-3 years to come about energy efficiency?

- Have committed investment budget, personnel to deploy not?

- The role of each department in the implementation process, what is?

Clear commitment will motivate spread to the entire staff help the next action occurred synchronously, have focus.

Step 2. Assessment determine the area consumption of the

Before improvement, business need to understand is using energy as the how. In this step, it should proceed:

- Inventory of equipment power consumption, large (machinery, lighting, air conditioning...)

- Measure the amount of electricity/fuel consumption according to each department or area

- Define the abnormality, energy loss potential

For example: A factory discovered 40% of the total power is focused on the area kilns, the majority of which are in rush hour. From here, they adjust production shifts to save nearly 10% of the cost of power without slowing down the progress of the delivery.

The assessment should be done by the internal engineering has the expertise, or in conjunction with the consultant specializing in energy to ensure objectivity in full.

Step 3. Set indicator measure target specific savings

There is no specific target is not able to evaluate the effectiveness. Enterprises need to build the index, energy management (EnPIs – Energy Performance Indicators) in accordance with the peculiarities of his own, for example:

- kWh/product output

- The amount of gas consumed for each ton of

- Energy costs per revenue

From these metrics, businesses can set clear goals such as:

- A 10% reduction in electricity consumption per unit of product in the next 6 months

- Reduce total energy costs by 15% in fiscal year

This helps the entire organization has the same orientation easily track progress.

Step 4. Build action plans, and training personnel.

Based on the results of the assessment, set goals business need to plan specific actions include:

- Technical measures: replace old equipment, optimum process operating

- Behavioral measures: adjusted the habit of using electrical layout shifts reasonable

- The category of investment (if any): as the installation of surveillance equipment, sensors, software, EMS

In parallel, the need to organize training for employees of all levels, not only on technical but also on the thinking and culture, energy saving. When the operator understand why you have to save the same way effective the execution will be easy to sustainability is much more than the only impose regulations.

Step 5. Track improvements, and (if necessary) prepare the ISO 50001 certification

Energy management is a continuous process. Businesses need to establish mechanisms for periodic monitoring indicators, to assess the effectiveness of each measure timely adjustment. The support tools such as dashboard, intuitive software EMS or summary table in Excel will be very useful.

When the system has stable operation, the business can consider to upgrade to international standards by:

- Standardized management process according to ISO 50001

- Construction documents prove effective

- Invited by the organization certified independent reviews

Though not required, certification to ISO 50001 is important advantage to assert the most prestigious is when working with international partners, or need to report ESG.

View details about system energy management Here.

4. Common mistakes when implementing energy management

Many organizations when deploying've encountered the common mistakes that cause results not achieved as expected. Here are four common mistakes and direction dealt with accordingly.

4.1. Just focus on equipment, neglected human factor

One of the most common misunderstandings is that energy management is synonymous with the investment in modern equipment such as machinery, power saving lamp, LED or sensor system. However, equipment is only part of the problem. If the operator still maintain the habit of wasting as to the machine idling, turn on the air conditioning when not needed or lack of consciousness of saving power, the modern equipment also does not promote efficiency.

Solution: Businesses need a combination of investment in equipment with training and internal communication to create change awareness. For example, the construction of the training sessions short, about the use of energy efficiency, encourage the initiative power savings from workers or the organization emulation between the parts to create motivation to participate.

4.2. Without measurable goals, clear

Many businesses implement energy management with general expectations such as “reduce your bills” or “save more than years ago” but not given specific goals, how to measure results. As a result, after a deployment time, the leadership did not know has improved is how much effective to from where should continue to invest in certain stage.

Solution: set specific indicators, for example:

- Up 8% of the power consumption on each product produced in 6 months

- Maintain performance energy use (EnPI) at a level below 10 kWh/m2/year for the building

This helps businesses easily track progress, evaluate results decision at the right time.

4.3. Lack of control over data or track only periodically

A big mistake again is just test data, the energy at the end of month or end of quarter, when all costs have been incurred very difficult to adjust in a timely manner. In addition, many businesses still depend entirely on the total bill but didn't know what power to be used in any area, which devices are consuming the most.

Solution: deploy the system energy monitoring in real-time from small-scale as the measured power for particular areas to software EMS integration if the business has multiple branches or workshop. This helps to detect abnormalities as soon as that occurs, save time and cost of remediation.

4.4. There is no process for continuous improvement

After achieving some early achievements, many businesses fall into a state of “somewhat satisfied” and stop tracking, update the measures to save new. Meanwhile, the need to use energy constantly change according to the season, according to production volume, according to the conditions of device operation. If no timely update, the system will quickly become less effective.

Solution: set cycle rate quarterly or half-year. Based on the measurement data, businesses should:

- Comparison with set goals

- Revise the points still wasting not be handled

- Suggestions for more improvement initiative (may be from the hr internal)

In addition, the apply frame standards such as ISO 50001 will also help businesses maintain a culture of continuous improvement system.

5. Solutions to manage energy from Lac – Integrated technology, flexibility to scale business

While many businesses are still struggling with the method of energy management craft, discrete or lack of reliable data for decision-making, the solution is from Vietnam has opened a more modern: digitizing the whole process of monitoring the optimal energy helps businesses save, transparency and accelerate switch green.

5.1. Energy monitoring in real-time, integrated data intelligence

Other than keeping track craft often delay to errors and solutions to manage energy of Vietnam using sensor technology and measurement systems automatically allowing business:

- Track energy consumption in real-time in each area, machinery, necklaces

- Visualise your data as a chart, control panel is easy to understand

- Receive alerts when consumption exceeds the threshold settings, or have unusual fluctuations

Help business no longer “passive” with electric bill last month that can detect timely wasting right adjustments in operating daily.

5.2. Automate reporting of emissions compliance to international standards

In parallel with energy tracking system business support measurement report emissions greenhouse gases (CO₂, CH₄, N₂O...) according to the standard, GHG Protocol and towards ISO 50001.

Specific:

- Automatically calculate emissions according to each activity (manufacturing, electricity, fuel, transportation)

- Create periodic reports as required by department ESG or foreign partners

- Support proven capacity management emissions when businesses participate in international tender or report sustainable development

This solution solved the problem of “don't know where to start,” that many businesses encounter when building management system, emission internal.

5.3. Flexibility caophù fit for both small businesses and corporations, large production

A strong point of the solution Lac Viet is the ability to customize expands with each stage. Enterprises can start from small range:

- Only power tracking in a production area

- Monitoring air conditioning or lighting systems in buildings

Then gradually expand to other areas, integrated sensor for water, compressed air, steam, water... without the need to change the whole system.

Thanks to this characteristic, the solution of Vietnam not only for plants, but also particularly suitable for:

- Small and medium sized businesses want to optimize operation, but a limited budget

- Office, hospital, commercial center, school... want to track power savings by region

Solutions energy management from Vietnam is not merely a software to track only number of power which is a platform conversion of energy comprehensive business support, from the cost savings, reduce emissions to assert prestigious sustainable with partners, customers and investors.

You can start from small but fall is of great value.

Get a free consultation to build the roadmap energy management in accordance with the peculiarities of your business at https://lacviet.vn/giai-phap-quan-ly-nang-luong-va-giam-phat-thai-carbon

Energy management't have to be the single technique that is a strategic operation overall. Businesses need access to long-term thinking, retrieve data center, human as the foundation and improvement is the motivation to build such a system actually effective and sustainable.