Lạc Việt ERP cho ngành công nghiệp phụ trợ là giải pháp quản trị tổng thể cho phép doanh nghiệp kết nối cũng như quản lý đồng bộ các hoạt động từ mua hàng – nhà cung cấp, tồn kho, sản xuất đến chất lượng và chi phí. Thay vì vận hành rời rạc theo từng bộ phận, hệ thống giúp chuẩn hóa quy trình, nâng cao khả năng lập kế hoạch, kiểm soát tốt nguồn lực – chi phí, qua đó cải thiện hiệu quả vận hành gia tăng năng suất một cách bền vững.

The article below Lac Viet will help the business have the overall look, from the context of the industry, real state management to benefits, orientation, deployment ERP effective in the long term.

1. Overview of ERP for supporting industry

1.1. Supporting industries is what? Why need admin depth?

Supporting industry system is the enterprise specialized in production of components, spare parts, semi-finished products and raw material input, serving directly to the manufacturing industry essential, such as: automotive, electronics, mechanical, textile, leather and shoes. Although the product does not directly to the end consumer, but this is the important foundation decided to continuity, quality as well as efficiency of the entire production chain finished product.

In the modern supply chain, business industry support plays a critical role with respect to the whole mass production:

- Steady progress of the whole chain: Supply components and raw materials the right time to help the stitching assembly, finishing out the right plan. Just a chain delay can also affect the entire delivery commitments.

- Quality control input: High-quality components auxiliary decide to direct quality end product. Errors from the first chain to increase the error rate, the cost of overcoming affect corporate reputation.

- Increase the localization rate, reduce dependence on imports: business development support to help reduce costs, proactive supply aims to raise the profile of businesses in the global supply chain.

Industrial enterprises auxiliary common challenges operated peculiarities that the methods of traditional management such as Excel or system discrete difficult to meet efficiency:

- Lot code & product variant: the Number of SKU, big change according to each customer makes keeping track, planning and controlling the output to false if no data focus.

- Production under the order (Make-to-Order): small orders, constantly changing, high requirements on the progress as well as quality requires the business to understand the production capacity, inventory and material resources in real time.

- Requirements traceability & transparency data: Customers, especially FDI, request access components, quality reports, as well as progress quickly and accurately. Distributed data easily cause delay, the risk of losing orders.

- Pressure control cost & prices: volatility of raw materials, competitive prices, forcing companies to analyze the prices of details to take business decisions accurately.

In summary, with key roles in supply chain, business supporting industries need a system admin sufficient depth and focus. For organizations looking to understand ERP supporting industry, understanding the peculiarities of this is the foundation to invest in the right solution to help stabilize the production and control costs to improve competitiveness in the long term.

1.2. ERP for supporting industry what is?

ERP for industry support is the solution strategic management helps enterprises optimize operational efficiency rather than just a technological tool. ERP systems integrate data and core processes on a unified platform, replacing the management discretization using Excel or software alone. Thanks to that, businesses reduce data discrepancies, limiting the action to shorten the time to handle the job.

ERP industry help related information, data purchase, production, inventory, and finance on a unified system. Thanks to that, the business had just detailed control at each stage, just get the picture operating overall.

In summary, ERP support industry, not merely as tools of technology that is tool management strategy to help businesses switch of the machine to operate, improve management efficiency, reduce costs, create data platform to sustainable development in a competitive environment increasingly fierce.

Example illustration: A business machining mechanical components get orders of 5,000 detail from customer FDI but the former managing discrete in Excel, between warehouses, planning and accounting. Leads to a lack of raw materials, slow progress, as well as the cost incurred in addition to the expected.

When applying ERP system, automatically check inventory, proposed purchase, update the progress recorded costs in real-time for each order. Thanks to that, the business control good progress, punctual delivery, to improve the ability to meet the order complex, high-demand.

- Lac Viet ERP for food industry: management solutions, comprehensive for the enterprise production – food distribution

- System LV ERP for chemical industry: solutions & selection criteria ERP suitable for business

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Solution Vietnam ERP for hotel: 6 features to improve operational efficiency

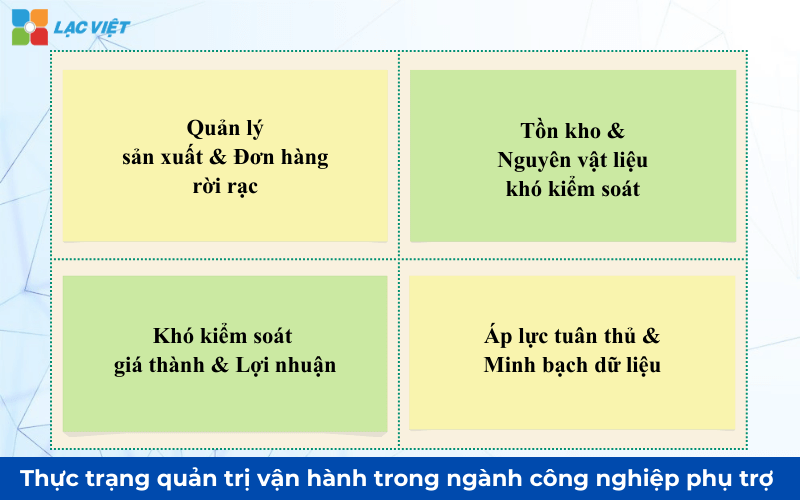

2. Real state operation management in business support industry today

In the context of competition is getting fiercer and international customers high demands on quality, progress, many businesses in Vietnam still operate according to the method of traditional management. This creates limitations in the operating deterioration of competitiveness in the global supply chain.

2.1. Production management & order discrete

Currently, the majority of enterprises in supporting industries still planning production progress tracking orders according to the method manually, or use multiple worksheets independently without flow data link system.... The “discrete” is in the present:

- Data from sales, production planning, warehouse, that the machines are not synchronized, creating “blind spots” in management.

- When the customer change the amount or time of delivery, the update through many stages to false, the response is slow. The shortage of transparency data, which the decision-making process is delayed, production forecasts less accurate.

As a consequence, business difficult to control the tempo according to each stage, increasing the risk late and incurred costs in addition to the plan, especially with the orders, OEM or FDI requires discipline tempo high. The standardization process-related data to help businesses faster response to customer requirements, at the same time significantly reducing errors due to manual processing.

2.2. Inventory & materials difficult to control

Inventory control of raw materials is one of the pain points of business auxiliary production. When there is no system for unified management, data input – output – inventory is scattered between many parts such as inventory, purchasing, production planning and accounting, making the overall control becomes difficult, teen accurate.

- Business easy to fall into a state of inventory, excessive: due to the purchase of raw material not sticking to the demand of production and orders, to cause misappropriation of funds as well as increase the costs of storage. As a consequence, increased risk of shrinkage, obsolescence reduces the efficient use of capital.

- Conversely, if the forecast track raw material, not exact: easy-to-make production interruption, delay delivery schedule. Just missing a detail input can also stop production line, the cost incurred to affect corporate reputation in the supply chain.

In addition, access to raw materials in batches, by serial number, and date as is required when working with large corporations. Lack of management tools tailored made business difficult feedback fast, easy to errors when providing information. This directly affects the reputation, opportunity, long-term cooperation.

2.3. Hard to control prices & profits in order

Cost data in many business auxiliary production is dispersed between the parts, tools, different management. When lack of management system integration, the expenses are not linked in the same context operation. This makes controlling the price of inaccuracy, not timely.

- The cost of materials, labor and production are not composite sync makes business difficult to determine the actual cost, according to each stage or orders. The recorded slow, allocation of estimated distort the painting price.

- Business no dissection is cost, according to each order or products, leading to the assessment of effectiveness is based more on experience rather than data. As a consequence, many orders have revenue but profits are low, even suffer losses.

As a consequence, the business difficulties in the pricing of the product, especially when you need a quick quote or offer for a competitive price. Lack of cost data, details make the selection order, the customer strategy inaccurate. At the same time, production planning, investment also lack the trust database to optimal.

Not only that, the no look transparent on the prices of longer makes business easy to fall into the status of “potential loss”, i.e. just discovered your order is not effective when completed production or when the final states. This reduces the ability to react promptly, increasing financial risks in the long term.

2.4. Pressure to comply with the standard & transparent data

In the context involved in the global supply chain, business auxiliary production pressure on compliance with the standard as well as transparent data. Specifically, the business must meet more rigorous requirements, including:

- Ability traceability of raw materials and products in batches, according to production stage. Teen tracking system throughout makes the retrieval, crafts, spending time errors.

- Provide reports about production, inventory, quality, periodically or irregularly. When managing discrete synthetic data is often slow, inconsistent, difficult to reflect the true operating condition.

- Ensure data consistency, accuracy as well as timely updates of the service audit, periodic review. The use of many tools in discrete reduce the reliability of data, affect the evaluation results.

If commissioning data distributed between many software, excel file, the synthesis of accurate reports about production, inventory and quality becomes very difficult. Business vulnerable to false information, loss of control, when unscheduled inspections. This directly affects the reputation, the ability to cooperate with big customers.

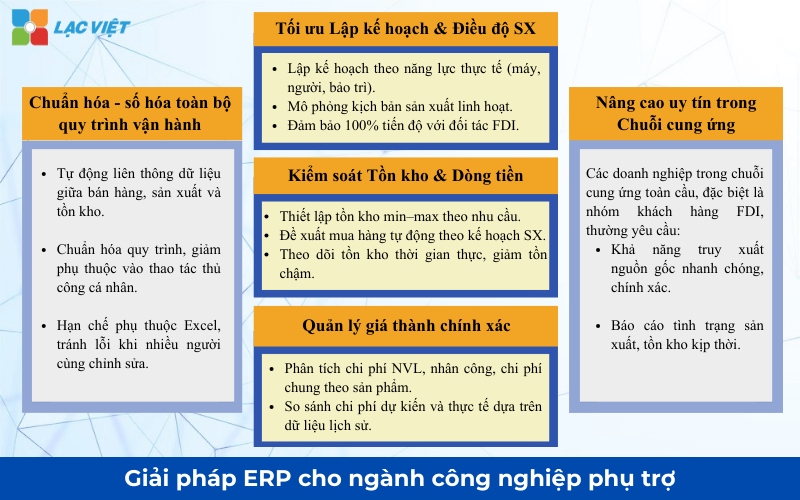

3. ERP for supporting industry to bring what value for business?

ERP is the system of governance overall, connect the activity from sales, purchase, inventory, manufacturing to finance on a unified platform. With business auxiliary production, transfer from admin discrete to integrated systems bring value operation clear and easy to measure.

3.1. Standardized – the number of turns the whole operation process

In many businesses, operating procedures is maintained by Excel, email and the tools individually. Meanwhile, each of these departments have “copies” of data, which leads to discrepancies, duplicate difficult synthesis. ERP for industry assistance:

- Data connection between the parts in an automatic way, i.e. when there is change in sales, then plan the production – inventory is also updated immediately.

- Standardize processes in a flow uniformly reduce dependence on the experience of the individual, avoiding the risk of errors due to the update manually.

- Reduction depends on the standalone tool such as Excel, where the data error-prone if many people editing.

Core values lies in the consistency of information as well as the ability to react quickly to changes of market and customers. When the data is standardized, as well as instant updates, businesses can track the progress of production, inventory, and planned purchase orders in real-time, limiting the risk decisions based on data deviations.

3.2. Improve efficiency-planning – production coordinator

One of the biggest challenges of the business and is planning production in accordance with the actual capacity of resources (machines, workers, shift). Planning craft often leads to:

- Production targets are not consistent with the machinery,

- It shifts the lack of effective

- Adjustable difficulty when orders change suddenly.

ERP allows:

- Planning based on actual capacity, considering factors such as machine capacity, maintenance status and work schedule of personnel.

- Simulation scenarios produced when there is a change in order or raw materials.

- Adjust plans quickly, more accurate when there are fluctuations.

Ability to meet committed delivery schedule decided to direct the level of reliability of the business with customers, especially the big clients or partners in the global supply chain.

3.3. Inventory control – cash flow efficiency

Inventory is a factor that causes great expense if not controlled properly. Data deviation or delay can lead to:

- Excess inventory, accounting for working capital,

- Lack of raw materials when the need to fold, causing delay to the progress of production.

ERP for industry support business:

- Set inventory levels, minimum – maximum based on actual demand, historical data.

- Auto-suggest purchase plan based on production schedules, and material consumption.

- Inventory reduction slow rotation by tracking inventory in real time.

This helps to improve the efficient use of capital, reducing the costs of storage, thereby improving cash flow, increasing the possibility of re-investment for the business.

3.4. Management reviews of the exact product for each order

One of the value key that businesses desire to not only know the overall cost, which is to know the cost of each type of product, every single order. System with distributed data, this almost can't be done efficiently.

ERP provides:

- Tool cost analysis, raw materials, labor cost, cost of joint production by each unit of product.

- Data accompanied by historical fact help you compare the cost of expected and actual costs.

This is the ability to accurately identify profitable products to adjustment strategies price matching, optimal product portfolio according to the profit target.

3.5. Increased ability to meet the requirements of large customers

Businesses in the global supply chain, particularly groups of customers FDI, usually requires:

- Ability traceability fast, accurate

- Status report production, inventory, timely

ERP allows to link information from multiple sources report accurately on request support:

- Retrieving data in batches, seri

- Provide transparency report for the customer or partner audit.

This is to enhance corporate reputation increases the likelihood of winning bid, as well as retaining contracts with large customers. Something that many organizations and businesses are to find out information about ERP for supporting industry special concern.

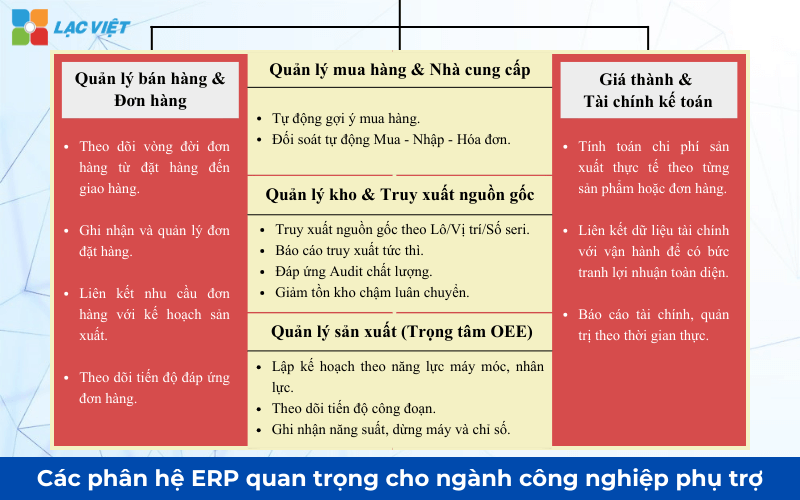

4. The analysis ERP important for supporting industry

In the ERP system, the modules link together to create the painting operation management throughout. With business, industry support, the selection of the correct implementation of the decisions efficient extraction system. Below is the analysis of the role and value of each subsystem.

4.1. Sales management & order production

This module allows businesses to track, from the time the customer placed orders, until the menu is the production and delivery completion. It noted not only orders but also link the data on production needs, plan meet.

With the traditional management, data orders are usually scattered in email, Excel file or software, individual departments, which leads to:

- Lack of cross-cutting between sales, manufacturing

- Slow response when customer change requests

- Elusive situation inventory orders.

ERP remedy this situation by linking direct orders, production plan, inventory. When orders are entered into the system, the demand for raw materials, production capacity and progress is synchronized display for the parts. Thanks to that, the enterprise shorten the duration of customer feedback, to avoid producing wrong or missing supplies and optimal delivery schedule.

4.2. Management, purchasing & suppliers

This module is responsible for the purchasing process, from identifying needs to control with the supplier. With industry support, this is stitching as materials constitute the bulk input costs do directly affect the production schedule.

If purchasing manager manually:

- Business is usually slow to respond to fluctuations in inventory

- Difficult to track, evaluate the effectiveness of each provider,

- Easy-to-happen errors in collated order – delivery menu – invoices.

ERP system for supporting industry automation management purchase through the petition order-based inventory, production planning and efficient tracking suppliers, collated automatic single purchase – receipt – invoice. Thanks to that, businesses reduce the risk of interrupting the supply chain, improve efficiency negotiations as well as shorten the processing time of purchase.

4.3. Inventory management & traceability

Inventory management in supporting industry not only recorded the number of export – import, but also related to traceability in batches and serial numbers, specifically, when a client requests data quality or the conduct of the audit.

In fact, many businesses still manage inventory using a spreadsheet, leading to:

- Data inventory lack of real-time

- Difficult traceability shipment when you need quality report,

- Uncontrolled inventory, slow-moving or expired.

The ERP system allows to track inventory by lot, warehouse location and serial number simultaneously provide reports traceability when needed. The reduction update help shorten the duration of inventory and limit errors. Thanks to that, the business enhance the ability to meet the access requirements as well as reduce the cost of excess inventory.

4.4. Production management

Manufacturing module in ERP is the heart of the operating production runs. This is the place:

- Construction of the production plan according to the actual capacity of machinery, human resources

- Track progress at each stage

- Recorded productivity, downtime, and the performance index to another.

Concepts such as OEE (Overall Equipment Effectiveness), i.e. efficient use of equipment, are taken into ERP to help business measure:

- Time the device actually works,

- The quality of products produced,

- Ability to leverage resources.

ERP for industry help business executive produced based on data in real time, proactively detect discrepancies and adjust resources in a timely manner. Thanks to that, production time is shortened, the capacity to meet orders increased as well as operating costs, poor efficiency is minimized.

4.5. Cost management & financial accounting

This module helps businesses:

- Calculate the cost of the actual production in each product or order

- Link financial data to operate to have paintings profit comprehensive

- Financial statements, management in real time.

In the traditional method, many businesses have trouble:

- Separating the specific cost for each unit of product

- Synchronize accounting data with production data warehouse

- Updates costs incurred quickly and accurately.

ERP link financial data from the modules of sales, purchase, warehouse and manufacturing to determine the exact cost, compared with the estimate. Thanks to that, the leader has data base for decisions about price, the price as well as product strategy long-term.

- ERP printing what is? Standardized process & criteria for selecting ERP – Lac Viet ERP

- ERP industry furnitures: Functions & selection criteria ERP – Lac Viet ERP

- ERP industry equipment what is power? Any solution help BUSINESSES fully managed? – Lac Viet ERP

- Solution Vietnam ERP for textile industry standards & compliance legal

5. Solution Vietnam ERP for supporting industry

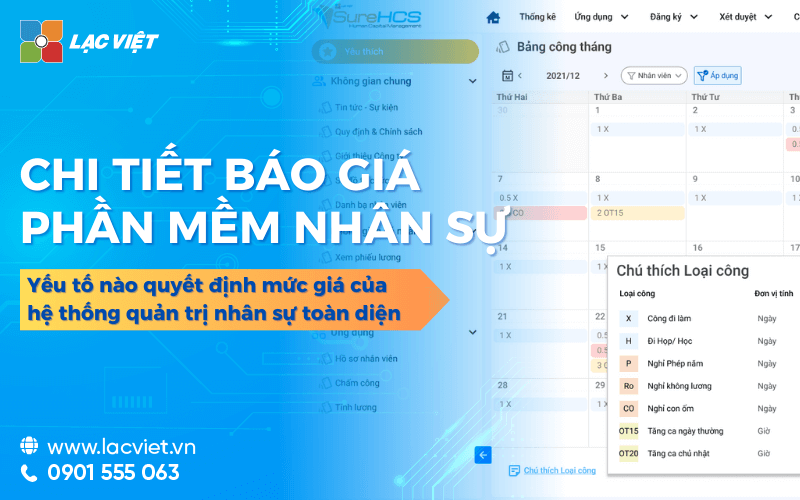

Trong bối cảnh doanh nghiệp công nghiệp phụ trợ Việt Nam chịu áp lực lớn từ khách hàng FDI, bài toán không chỉ là có ERP cho ngành công nghiệp phụ trợ mà là chọn giải pháp phù hợp với thực tế vận hành. LV ERP của Lạc Việt vì vậy đang được nhiều doanh nghiệp sản xuất, công nghiệp phụ trợ quan tâm.

5.1. Overview of Lac Viet ERP

Lac Viet ERP (LV ERP) as ERP solution due to Lac development, is designed based on more than 30 years of experience in implementing software management for business in Vietnam. Especially in the field of manufacturing, industrial auxiliary.

Unlike many ERP solutions international capital requires the business to have “changed to match software”, LV ERP is build by thinking the opposite: the software must be adapted to the model of governance, capacity actual operation of the enterprise.

LV ERP to work towards:

- Standardize, digitize the entire process of administration core

- Keep the system easy to use with team did not operate in-depth about IT

- Ensure scalability as your business grows or become more deeply involved in the global supply chain.

With this orientation, LV ERP not only suitable for medium-sized enterprises & large, which is also a viable option for businesses supporting industries are in the process of upgrading the system administrator.

5.2. LV ERP response problem management ancillary industries like?

Industrial enterprises, usually having three big problem: control throughout the process – flexible as orders – meet transparency requirements from customers. LV ERP is designed to directly address these issues.

- Quản lý toàn bộ chuỗi vận hành trên một nền tảng thống nhất từ bán hàng đến sản xuất, tài chính. Đơn hàng được ghi nhận sẽ tự động liên thông kế hoạch sản xuất, vật tư và dòng tiền. Nhờ đó, doanh nghiệp giảm rời rạc dữ liệu giúp lãnh đạo nắm bắt vận hành theo thời gian thực.

- Hỗ trợ linh hoạt sản xuất theo đơn, theo dõi từng đơn hàng từ báo giá đến giao hàng. Hệ thống quản lý chi phí – giá thành – lợi nhuận theo từng hợp đồng. Doanh nghiệp kiểm soát hiệu quả từng đơn hàng thay vì chỉ nhìn kết quả cuối kỳ.

- Hỗ trợ truy xuất nguồn gốc báo cáo quản trị minh bạch nhờ quản lý tồn kho theo lô, seri và lịch sử sản xuất. Doanh nghiệp có thể nhanh chóng xuất báo cáo về nguồn gốc, chất lượng, tiến độ hoặc chi phí từ dữ liệu tập trung. Qua đó đáp ứng tốt yêu cầu của khách hàng FDI, nâng cao độ tin cậy trong chuỗi cung ứng.

5.3 long-term value LV ERP bring business industrial auxiliary

The deployment LV ERP not only to solve the problem operate before the eyes, but also create the foundation for sustainable development. Specific:

- Business step by step, moving from governance based on experience to management based on data

- Enhance the ability of cost control, cash flow

- Increase capacity to meet the governance standards, transparency international.

With respect to the organizations and enterprises are to find out information about ERP for supporting industries, LV ERP of Lac Viet is an option worth considering thanks to the balance between intensive management in production, as well as the appropriate level with practical to operate in Vietnam.

In the context of supporting industry increasingly high pressure on the progress, quality and transparency of data, the system upgrade operation management is the indispensable requirement. ERP for supporting industry not only helps businesses better control of production, inventory, and cost, but also create the foundation data to make decisions more accurate.

- Lac Viet ERP in construction industry management intensive treatment for DN in Vietnam

- ERP retail industry what is? Solution Lac Viet ERP optimal operation & sustainable growth

- Lac Viet ERP industry, medical equipment, operation management meet quality standards & compliance legal

- Lac Viet ERP mechanical engineering: Analysis & Solution ERP enterprise