ERP for textile industry is system integrated management help enterprises manage from orders, production plan to inventory and finance on a unified platform. The system supports tracking the progress of each stage, control of raw materials, as well as calculate the price according to order. Thanks to real-time data, business, reducing waste, ensuring the delivery schedule meet the requirements of international customers.

The article below Lac Viet will the same business find out details about ERP software for garment, what is the need to deploy and ERP brings practical value in how to operate the daily.

1. ERP for textile industry is what? Why textile business need ERP?

ERP for textile industry is system management software business is specifically designed to manage the entire operation of the textile business on a unified platform. System connection throughout the stitches from receiving orders, production planning, purchase management, materials, cutting – sewing – finishing to inventory management and finance.

In the textile business, ERP data set from the departments into a unified system instead of managing discrete multiple Excel file. Thanks to that, the information is updated in real-time, easy lookup, coordination throughout your entire operation process.

ERP software for garment other nothing compared to ERP usual?

ERP is a general concept for all industry – producers of services. However, each industry has characteristics different operating requirements of the textile business set out the criteria that separate an ERP system typically not able to respond effectively if they are not designed peculiarities.

Below is a comparison table to help clarify ERP garment industry other nothing compared to ERP usually focus on the angle actual operation of the enterprise:

| Criteria | ERP casual | ERP for textile industry |

| Range design | Use common to many industry-production – services | Specifically designed for the peculiarities textile |

| Production management | According to the production process overview | In order FOB/CM/ODM, multiple stages in a row |

| Track progress | Track at the aggregate level | Track details each stage: cutting – sewing – finishing |

| Manage raw materials | Inventory management basic code supplies | Management fabric according to the color – gauge – batch document under code details |

| Link planning – inventory | The link at the basic level | Fastened production planning with inventory NPL follow each order |

| Pressure delivery | Less concentrated elements progress | Optimal control progress, limiting the delay unit and penalty contract |

| Access & standards | Access to data at the level of general | Meet traceability to international standards, ESG |

| Management reports | Financial statements, inventory | Progress reports, orders, productivity passes, the cost of prescription |

The comparison table above shows the ERP textile industry not only as “ERP + production,” which is the system built based on the way the textile industry operated fact, help businesses better control schedule, cost, and capacity to meet the demanding requirements from international customers.

Illustrative example: track orders FOB by ERP

A business may receive orders FOB (Free on Board orders, responsible for delivery, seller is, to the port of export). If operated manually, each department using Excel and own software:

- Business send information order;

- Purchasing department independent demand and supplies;

- Production planning cut – sewing;

- Warehouse inventory of raw materials;

- General accounting final.

Data needs for projectors to each other constantly easy to be amiss, take time.

With ERP for textile industry, everything is connected automatically:

- When the order is created, the data sent to the purchasing department and production.

- The system automatically calculates demand fabric, accessory according to orders.

- The production plan is based on capacity, volleyball, schedule delivery.

- Mode step by step (put fabric trim – sewing, finishing) are tracked in real time.

- When next day delivery, leadership has the overall report on the progress, costs, and risks.

This approach not only save time, reduce errors, but also help enterprises optimize resources to ensure the progress of delivery, essential in international competition.

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Giải pháp Lạc Việt ERP cho khách sạn: 6 tính năng nâng cao hiệu quả vận hành

- ERP ngành in ấn là gì? Chuẩn hóa quy trình & tiêu chí lựa chọn ERP – Lạc Việt ERP

- ERP ngành nội thất: Chức năng & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP

2. Special operation, causing the textile industry “mandatory” to use ERP

Operations in the textile business has many peculiarities complex, difficult to control if managed by Excel software, or discrete. Traditional way to develop risk, high cost and low efficiency. So, ERP for garment industry has become the strategic requirements instead of just a choice of technology.

2.1. Production chain multiple stages, interdependent

Process of textile production is often composed of multiple stages in a row, from receiving orders, prepare the raw material to cutting – sewing, finishing, quality check and delivery. Each stage depends closely on the previous paragraph, only need arises minor glitch can also affect the whole production progress.

If there is no system operation management concentration, business will be very hard to:

- Track actual progress according to each order.

- Coordinating the next stage when faced with incidents in the current segment.

- Timely response to fluctuations in demand or shortages of raw materials.

Meanwhile ERP for garment is designed to track progress of production according to each stage, updating data in real time. Thanks to that, the production planning department can promptly adjust the schedule when incurred fluctuations. This is especially important in the context of international customers put very high demands on the progress of delivery.

2.2. Manage raw material, extremely complex

The textile industry is not like the manufacturing industry, simple materials are very diverse and continuous fluctuations:

- Fabric by color, gauge, lot (lot, batch)

- Only, the accessories according to the model, size, demand of orders

- The loss of supplies in the process of cutting – sewing – finishing.

No system of inventory management concentration, business meeting status:

- Lack of raw materials in one stage

- Inventory can't use due to incorrect classification

- Costs of storage increased due to excessive stockpile

An ERP software for textile industry optimise inventory tracking in batches and location, automatically prompt order when inventory drops below the safety threshold, which helps control the cost or risk disruptions to production. This just optimum costs, inventory costs, while ensuring supply continuity for production.

2.3. Pressure delivery from international customers

International customers, especially the big brands, sets out the criteria very high On On-Time Delivery (delivery term). Late progress leads not only to a fine contract, which also affects the credibility, that business can take a chance to get orders in the future.

When the source discrete data can not provide visualize exactly about overall progress, the board don't have enough data to decisions in a timely manner. On the contrary, with ERP, data is continuously updated and homogeneous help business:

- Track actual progress under orders

- Early detection, treatment obstructive

- Planning capacity adjustment now when there are deviations.

The modern ERP system allows businesses to enhance reliability in delivery plan – the determining factor in relations with the international customers.

2.4. Requirements traceability & compliance ESG is increasingly high

In the context of the global supply chain more transparent, the business not only being asked about the progress, the cost of which must also demonstrate compliance with the standards of environmental, social and governance (ESG). ESG is no longer a trend that is required to maintain trade relations with the label order.

The proof of origin of raw materials, adhere to the production process as well as preparation service record audit (audit) is an extremely time-consuming if done manually. ERP helps to normalize this data, create:

- Record traceability full batches of raw materials;

- Report meet the requirements of auditing, international partners;

- Database serve for the program sustainable development.

In fact, many textile business has determined that the ability to provide data transparency, compliance with ESG as factors directly affect the decision to maintain the partners of the big brands.

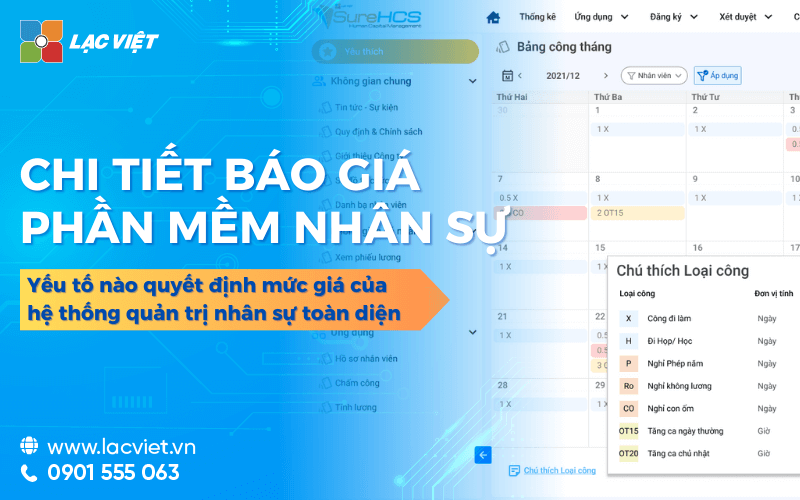

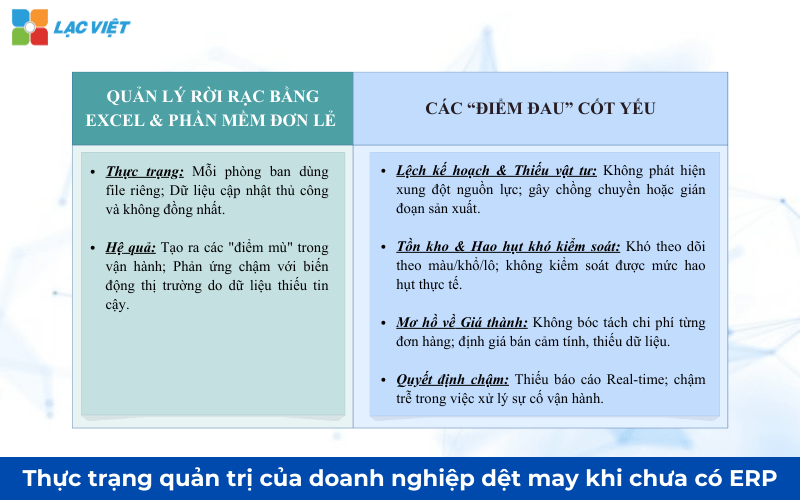

3. Real state management of the textile business when there are no ERP

Many textile business still operated by Excel and the software discrete, causing scattered data, difficult to control. When the scale and complexity increase, the limit is more clearly revealed. The lack of ERP garment industry integrated to reduce the effective governance, competitiveness of the business.

3.1. Manage discrete, Excel, software, single

Many textile business still choose the method of management by Excel for production planning, inventory, financial reports, combined with the software singly for accounting or hr. The whole point of this is:

- Departments set up separate file, there is not a single data source to the projector.

- Each change must update manually from this file to another file.

- There is no way to automatically check the validity of data when multiple people work together on the different copies of the same content.

This fact leads to data inconsistency, easy-to-fault does not reflect the true situation operate real-time. Many studies on production management has indicated that the data scatter, updates slow creation of “blind spots” in the production, making the plan and react to market movements become sluggish, less efficient.

3.2. The “pain points” popular

The main issues arising from the management model discrete't just stop at difficult operation but also directly affect business results.

- Deviation plan, her husband makes, lack of raw materials: usually due to management discrete by Excel made business difficult to detect early conflict resources. As a consequence, progress is affected, arising interrupted production. ERP garment industry help contact information warehouse – buy – production to control active, reduce the cost.

- Difficult to control inventory & wastage of raw materials: the Lack of tools lot tracking, colour, why excess inventory shrinkage difficult to control and slow response because of the volatility. ERP allows inventory management, real-time alerts, lack of supplies, as well as the optimal purchasing plan.

- Do not calculate the price of reality in each order: distributed Data that businesses do not dissects the exact cost, margin by customer order. ERP integrated production – inventory – accounting – hr to calculate the price of real decision-support sales price based on the data.

- Leadership lack of data realtime to a decision: report manually slow down the reaction administrator before market movements. ERP textile industry provides data realtime on a single system, help leadership decision fast more accurate.

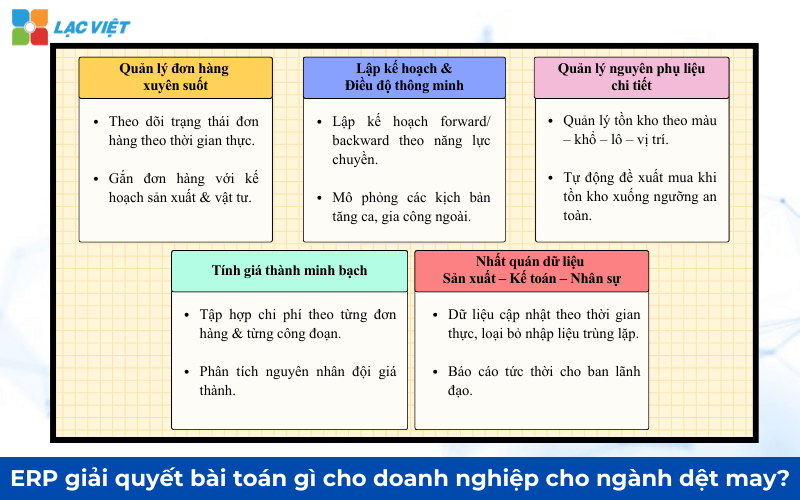

4. ERP for textile industry solve anything for the business?

Businesses are understanding, ERP for textile industry, it is important not feature which is worth ERP brings in actual operation. ERP garment industry focuses on solving the core issues of cost, schedule and performance of governance. Here are 5 group problem critical that the system can efficiently handle:

4.1. Manage your orders textile throughout from the beginning to the end

In the textile industry, orders are central govern the entire production planning, buying supplies and delivery. When the lack of system management throughout the enterprise easy-to-follow crafts, updates slow difficult to control the tempo real.

- Track order status in real time: ERP software for garment allows for continuous update order status from receiving to delivery to help the executives quickly identify orders with the risk of delay progress for timely adjustments.

- Attached orders with production planning & materials: Single row is directly linked with the plan passes, the demand for raw materials help layout production capacity as well as the preparation of materials the right time, limiting or excess.

Thanks for order management focus on ERP garment industry, business, reduce errors and control the progress better to raise the prestige delivery in the supply chain textile.

4.2 planning & production coordinator smart

In the textile industry, production plans need to keep abreast of the actual capacity of each line and each paragraph. If only based on experience or spreadsheet, craft business, easy to fall into the status husband makes too download as well as past due when the order increases.

- Planning forward/backward according to capacity makes: ERP for textile industry support plan forwards or backwards based on the date of delivery, actual capacity helps to clearly identify the time of each stage to avoid plans lack feasibility.

- Simulation scenarios increased ca, outsource: the System allows quick assessment of the project adjusted when order fluctuations, from which balance progress as well as the cost right from the stage of planning.

Thanks to that, the ERP industry may help the business actively ago fluctuations, reduce risk, delinquent, and enhanced reliability in delivery commitments to customers.

4.3 Management, raw material, accurate to every detail

In business of textile, raw material, variety of types, colors, fabric and shipment. If management tool discrete business is to develop, teen, supplies, excess inventory or production interruption due to false data.

- Inventory management according to the color – gauge – batch – position: ERP textile industry to enable tracking raw materials details to each attribute in the location, storage, helps businesses know the exact materials that you can use for each order, instead of just holding the number of the total.

- Auto-suggest buying when the inventory at the threshold of safety: monitoring System inventory in real time, and timely warning when private touches to a minimum, support purchasing department actively preparing, avoiding lack of raw materials in the production process.

Manage raw material, accurate on ERP industry may help your business reduce inventory to die, limit losses, maintain continuous production, at the same time control the cost of materials and efficient right from the start.

4.4 Calculate the cost of orders textile transparent, accurate

In the textile business, the identification of the profit and loss account as each order is big challenge when the cost of raw materials, workers and general expenses usually recorded discrete, causing the price of just an estimate, as well as lack of facilities decisions.

- The set costs according to each order & each stage: ERP textile industry recorded as well as the allocation of costs throughout from cutting, sewing, finishing to delivery, helping prices reflect the fact instead of the average.

- Cause analysis team cost: the System compares actual costs with the norm, quick to point out the passages or elements incurred cost overruns to make timely adjustments.

Thanks to price transparency, ERP industry may help the business know interest – hole each order and each customer, from which control the profit actually aimed at business decisions based on reliable data.

4.5 connecting production – accounting – human resources on a system

In many textile business, parts manufacturing, accounting, and personnel still operate discrete, causing data updates slow, the lack of consistency do a lot of work data entry back, especially when the scale the number of orders increases.

- Data updates in real-time, eliminate data entry duplication: ERP industry may allow the parts work together on a unified platform, all fluctuations in output, costs, and inventory are recorded instant, used for the whole system.

- Instantaneous reports for leadership: administration reports the synthesis is constantly updated, help leaders hold fast painting operation overall to a timely decision.

Thanks to connect the entire operation on an ERP system for the textile industry, business formation, “a source unified data”, enhance effective coordination internal to significantly shorten the duration of the decision.

5. Textile business should choose ERP like?

In fact, many textile business to select ERP according to the features or price, instead of the math operation management objective, long-term, which makes the system implementation less effective. Therefore, selecting ERP for textile industry should be considered as a strategic decision of the administrator.

- ERP must understand the peculiarities textile production: ERP industry may need to take orders-centered support plan according passes actual capacity management, raw materials detail. ERP, shared teen experience the industry often arise more custom, increase the cost as well as risk deployment.

- Flexible customized according to factory model: ERP must adapt the model FOB, CMT, many – to-many makes – more ca. The system should allow customize the way businesses operate, easy to expand when the scale changes, help ERP is accepted and effectively used.

- Fits standard accounting Vietnam & international practice: ERP needs to simultaneously meet the standards, the Vietnamese accounting requires management reports international. The close link between production and accounting help with data rates of accurate, reliable for decision management.

- Implementation experience and practice in the industry: For the savvy textile help businesses identify early risks, build the roadmap for a match. This is a decisive factor for ERP promoting value management sustainable in the long term.

Textile business should choose ERP based on the target control operation to sustainable growth, do not run according to features. ERP needs to understand the peculiarities of the industry, flexible production model to meet the accounting requirements management. Factors to properly implement decision system can create real value or not.

- ERP ngành thiết bị điện là gì? Giải pháp nào giúp DN quản trị toàn diện? – Lạc Việt ERP

- System LV ERP for chemical industry: solutions & selection criteria ERP suitable for business

- Lac Viet ERP in construction industry management intensive treatment for DN in Vietnam

- ERP ngành bán lẻ là gì? Giải pháp Lạc Việt ERP tối ưu vận hành & tăng trưởng bền vững

6. Lac Viet ERP – ERP Solution for textile and garment industry of Vietnam development

For many textile business in Vietnam, the biggest challenge when implementing ERP lies not in technology but in the level of fit with the way businesses are operated. This is also the reason Lac Viet ERP is Vietnam-based development practices, corporate governance, Vietnam, instead of copy machines models ERP abroad.

LV ERP not only is ERP software for garment industry, which is the platform overall administration, help businesses control sync from order, production, raw material, prices and financial and human resources on a single system.

Why LV ERP fit with textile business in Vietnam?

- Production management & planning makes depth: LV ERP planning according to the order associated with actual capacity each, volleyball, help detect early point congestion, coordination, flexibility to enhance the rate of punctual delivery (OTD).

- Manage inventory of raw materials to multi-dimensional: System inventory management according to color, gauge, plots, shrinkage than the norm. Help business to know the exact materials used for each order and inventory reduction dies, disruption of production.

- Calculate the price according to order & stages: LV ERP set costs in real time, to clarify the interest – hole and causes of discrepancies, support leadership decisions based on actual data.

- Connected manufacturing – accounting – human resources – report: Data to be focused updates realtime on a platform, eliminating data entry, duplicate, provide management reports consistently rapidly.

LV ERP is management platform long-term is Lac Viet developed to solve the problem at the core of ERP textile and garment industry in Vietnam such as cost control, ensure progress, data transparency, capacity building administrator, instead of running according to the number of features. Detailed information about the solution may refer to: https://erp.lacviet.vn/

ERP for textile industry is management platform to help businesses control operation transparent, proactive, before market movements. In the context of the production chain complex and demand from international customers increasingly, management-based data consistency becomes a competitive advantage core. Investment in ERP in the right direction to help optimize the cost, make sure to schedule delivery as well as create a platform for sustainable growth in the global supply chain.

- Lạc Việt ERP ngành thiết bị y tế quản trị vận hành đáp ứng chuẩn chất lượng & tuân thủ pháp lý

- Lạc Việt ERP cho ngành công nghiệp phụ trợ tối ưu quản trị sản xuất – chuỗi cung ứng cho DN Việt

- Lạc Việt ERP ngành cơ khí: Phân hệ & Giải pháp ERP phù hợp doanh nghiệp Việt

- ERP ngành thủy sản: Giải pháp & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP