ERP chemical industry is management solution overall is designed specifically for business chemicals, helps to control hazardous materials, manufacturing batches, quality and compliance, safety and environment. System connection throughout the purchase, inventory, manufacturing to finance, support traceability, reduce legal risks, contributing to the optimal operating costs.

The same Lac Viet find out detailed overall ERP for business in the chemical industry, from the real state management, application needs to the role of ERP in improving operational efficiency, sustainable development.

1. Overview of ERP for chemical industry

1.1. ERP industry, what is the chemical?

ERP chemical industry is system management software, integrated, designed to manage throughout the entire chain operation of the business of chemicals, from purchase of raw materials – inventory – production, quality control, environmental safety to financial accounting management reports. Instead of each department using a tool individually, ERP for chemical industry concentration data on a unified platform. Help business risk control, cost effective, operating in real time.

The difference compared with the ERP typically:

- Manage raw material chemicals associated with batch production, shelf life, safety information, instead of only according to the code – number.

- Support production batch (batch) according to the formula blends complex, quality control in multiple stages.

- Traceability two-dimensional, allowing for rapid identification material that has used for a batch production and vice versa.

- Integrated safety requirements, environment as well as compliance with legal now in operation process, reduce dependence on records.

- Data operator contact information with accounting and financial help to reflect the correct cost, price, efficiency business.

ERP for business, industry chemicals not only help the business, “better management,” which is more important than management, more secure, more transparent, ready to meet the compliance requirements of increasingly stringent of industry.

1.2. ERP for chemical industry other what ERP conventional production?

Below is the comparison table to clarify ERP for chemical industry other nothing compared to ERP conventional production, focusing on the perspective of operation and real value for business:

| Criteria for comparison | ERP conventional production | ERP for chemical industry |

| Materials management | Management, commodity code, quantity; less distinguished level of risk | Materials management hazardous, attach with safety information, storage conditions, SDS |

| Manage batches – batch – term use | Can manage lot, but usually at a basic level | Management details in batch, expiry date, storage conditions; support early warning, risk expire |

| Traceability | Access one-way, primarily serve internal control | Access two-way: from raw material → finished products, from the finished products → each batch of raw materials when the problem |

| Production & quality control | Produced according to the standard, the less volatility | Produced according to recipe, blend complex, quality control, multi-step, batch |

| Compliance with safety – environment – legal | Support in the general, much depends on processing craft | Design available to meet the requirements of chemical safety and environment. Legal records, inspection |

| Worth bringing back | Optimal operating base, reducing the manipulation craft | Decrease safety risks, legal. cost control, quality fast access when there is a problem |

This table helps the organizations and enterprises are to find out information about ERP for chemicals easy to see: the difference lies not in the “more features” that at the appropriate level with risk, peculiar operation of the chemical industry.

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Giải pháp Lạc Việt ERP cho khách sạn: 6 tính năng nâng cao hiệu quả vận hành

- ERP ngành in ấn là gì? Chuẩn hóa quy trình & tiêu chí lựa chọn ERP – Lạc Việt ERP

- ERP ngành nội thất: Chức năng & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP

2. Real state business management chemical now

From practical work with many business leaders chemicals, can see the pattern manager or software discrete quickly reveal risks as well as the excess cost when extended scale. The lack of synchronized data makes business difficult-to-control operation, meet compliance requirements increasingly high.

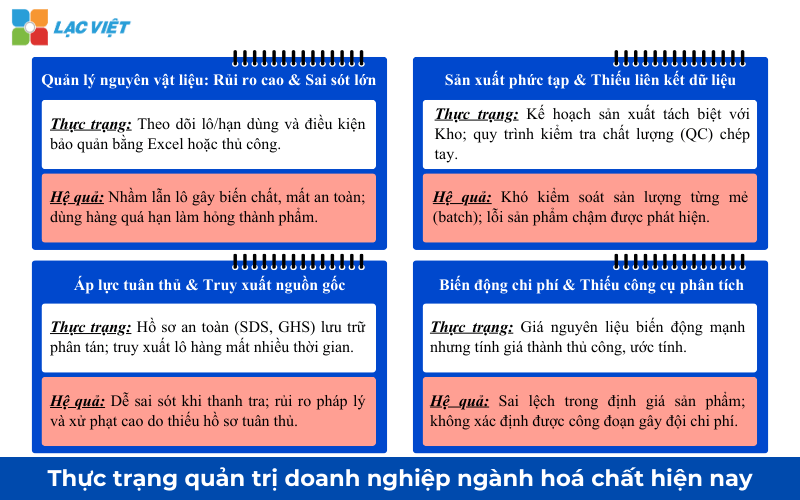

2.1. Manage raw material chemicals: high risk, small flaws – big consequences

Raw material in the production of chemicals is often the dangerous chemicals that require storage conditions, strict, limited clear broth. The use of Excel or the system is not integrated to track inventory and term use leads to the risk such as:

- Confused shipment, led to use of materials too limited in production, which affects the quality of finished products.

- Uncontrolled storage conditions (temperature, humidity...) according to the technical requirements, easy-to-happen variable quality or safety.

- Wrong number in the inventory report, which made planning the procurement of raw material not consistent with the actual production, causing “off” or “excess” material.

In summary, materials management, chemical requiring precise level control is very high. System discrete crafts to errors in lot tracking, shelf life and storage conditions. Small deviations, this can cause big risks on quality, operating costs.

2.2. Production chemicals complex & link data

Unlike the industry, simple production, chemical production often requires mixing formula, the complex, multi-step quality control in the process and requires rigorous tracking each “batch” production.

In fact operate:

- The production plan is built separate from the inventory, accounting leads to a lack of data synchronization.

- Data inventory not reflect the actual output in production due to lack of direct contact between the parts.

- Process quality check at each stage still take notes by hand and updated slowly, which increases the risk of error is not detected in a timely manner.

Chemical production requires data contact information from planning, inventory to accounting and quality control. When the parts operate discrete business is hard to determine the exact output, cost, and status of each batch. As a consequence, production efficiency, reduce risk, quality increase.

2.3. Pressure regulatory compliance, safety, environment, traceability

Industry chemicals is governed by many regulations on labor safety management of dangerous chemicals and environmental report. Which, requirements management, SDS (Safety Data Sheet), classification of chemicals according to GHS as well as traceability of each batch of products is not to be missed.

When the data is saved scattered, each time you check the legal, personnel must be synthesized from many different sources — just time consuming, and easy to errors. This not only interferes with the activity of normal production, but also can cause the business to meet heavy fines due to compliance violations.

The chemical industry, pressure grew on safety, the environment, as well as traceability according to the rules, such as SDS, GHS. When data is discrete storage, the meet the inspection becomes time consuming, easy to errors. This increases the risk of disruptions to production, violations of legal.

2.4. The cost of production fluctuations, but lack the tools to analyze price

The cost of raw materials in the chemical industry often constitute the bulk product price fluctuations depending on the supply and the import process, the market price. If the business is only based on the method of calculating the cost of or non-standard data management will have trouble:

- Not identified increased cost depends stitch how: purchase of raw materials, manufacturing or warehousing.

- Not properly calculate the price according to each production batch (batch cost), leading to discrepancies in the product price.

- Do not take a timely decision to adjust the production plan or the removal effective products business higher.

The cost of raw materials, chemical volatility, but many businesses lack the tool analyzes the price of accuracy. Not properly calculate the price according to each plot make it difficult to determine the cause team cost, easy to deviations in the price. As a consequence, decided to adjust production is often slow and inefficient.

3. Business chemicals would need to implement ERP?

Investment in ERP is a strategic decision, a direct impact on operational efficiency, risk management and growth of business. ERP solutions in the chemical industry to help integrate, standardize data according to specific industries, from it support business better control of the challenging operate. Below is the business group will receive the maximum value when implementing ERP:

- Business manufacture of basic chemicals: Usually medium-scale to large provider of platform products, such as acids, solvents, detergents. Operation requires strict management of raw materials in batches, limited user and control formula mixing, production quality. The cost of raw materials accounted for a large proportion, fluctuations in strong direct impact on the efficient, profitable business.

- Business, industrial chemicals, additives: Often serve various industries like textile, construction, food, plastic. Operation requires traceability clearly, management contracts, orders, inventory and shipping related areas. At the same time, enterprises must comply with strict safety standards, the environment in the entire product life cycle.

- Business cosmetics, chemical-pharmaceutical: There are very high requirements for quality, traceability, compliance with legal. Raw material supplier diversity processes, quality control, multi-step complex. At the same time, the business must meet strict regulations regarding labeling, safety certification, legal documents throughout the product life cycle.

- Commercial enterprise – distributor of chemicals: the role connecting manufacturers with markets, to manage diversified commodity in several batches and limited user. Pressure is located in the supply of inventory report transparent, accurate for client – partners. At the same time, enterprises must adhere strictly to the safety requirements of chemicals during storage and transportation.

Achievement, chemical companies have the scale, the level of operational complexity, we should implement ERP to control costs and risks. ERP will help standardize management, creating the foundation for sustainable growth.

4. ERP for chemical industry solved the problem for business?

In industry, chemical management systems, discrete make data lack of synchronization increases the risk and slow decision making. ERP for chemical remedy the point of congestion this platform, centralized data system.... Here's how ERP solve each problem core, the actual value that the business receives.

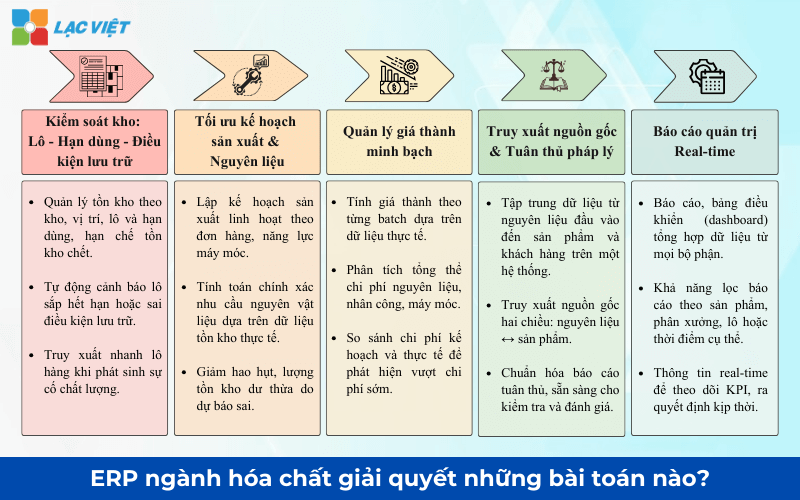

4.1. Inventory control chemicals in batches, expiry date, storage conditions

In chemicals, each raw materials or finished products come with a limited user, batch production as well as storage conditions peculiarities. This complexity made the track by Excel or window paper easily lead to confusion, losses and safety risks.

ERP solutions in the chemical industry to provide:

- Inventory management, multi-dimensional: in stock, location, batch and expiry help avoid inventory died (orders expire, can't use), reducing the need for working capital.

- Automatic warning when plots near expired or entered the wrong storage conditions.

- The ability to access fast shipment related the event of a quality to recover the processing, the right group of plots required.

Thanks to inventory control in batches, expiry date as well as storage conditions on a unified system. Business chemicals significantly reduced safety risks, losses and costs. More important, leaders can be proactive decisions based on accurate data, instead of troubleshooting when has arisen.

4.2. Optimal production planning & use of materials

Production planning in chemical not simply programmed machinery running according to the list. It must weigh:

- Recipe mix, level of inventory out there.

- Calculate the demand for raw materials according to the production schedule.

- Adjust the plan when the raw material price fluctuations or shortages.

ERP for chemical support:

- Plan flexible production according to orders, capacity machinery.

- Accurately calculate material requirements based on data inventory practice.

- Reduce the wastage, the amount of excess inventory due to the forecast wrong.

Thanks to the close connection between the production plan, inventory, recipe mix. ERP helps business chemicals, plan international, responsive ago fluctuations. The result is to reduce wastage of raw materials, to optimize costs and maintain production stability and safety.

4.3. Price management of manufacturing, chemical transparent, accurate

In chemicals, the cost of food is not just wrapped up in raw materials. It also includes workers, machinery, losses in the production process and packaging costs. No data focusing the price becomes guesswork, easy to deviations.

ERP for chemical industry allows:

- Calculate the price according to each batch production based on actual data.

- Cost analysis, raw materials, labor, machinery as a whole.

- Compare the cost of expectations with the actual cost, early detection of points incurred costs in excess of the plan.

ERP provides detailed reports to help leaders determine the exact product groups or chains incurred high costs. Thanks to that, the business timely adjusted to control prices as well as policy formulation more competitive price.

4.4. To meet the requirements traceability & compliance legal

Chemicals subject to the strict management of various specified local – international, including: requires records storage, retrieval batch products, quality control, and reporting of occupational safety. When data is distributed in many systems, preparing for tests or inspections become time consuming, easy to errors.

ERP systems in the chemical industry:

- Data set from raw material input to final products, customers in a single source.

- Allows traceability from both directions: from raw material to products and vice versa.

- Standardized reports adhere to ready for inspection from the management or the customer.

Standardized form and data to help businesses not only meet legal requirements but also reduce the time to prepare for examination, audit – from days down to hours – at the same time reduce the risk of penalties due to errors in profile.

4.5. A decision fast thanks to the system management reports in real time

One of the core values of ERP is the report is updated in real time. This means that leaders do not have to wait for reports from multiple departments, which can access data, inventory, expenses, orders, and production immediately.

ERP provides:

- The report, the panel (dashboard) aggregate data from every department.

- Ability to filter reports by product, factory, plot, or specific time.

- Information real-time to track KPIS, timely decisions.

In the context of market volatility, fast, instant information help businesses react to customer needs, adjust the production plan or purchase of raw materials before the deadline. From there, improve operational efficiency, competitiveness.

5. Selection criteria erp suitable for business, industry chemicals

For business chemical ERP only really valuable when solving the right problem, operating risk, the peculiarities of the industry. Choose the solution does not fit can cause wasted investment, affecting production operations – business. So, businesses need to focus on the core criteria when evaluating ERP for chemical industry.

- The ability to manage batches – batch – term use: is mandatory criteria of ERP solutions in the chemical industry. The system helps to track inventory in detail, to quickly retrieve the raw material batch production as well as prevent casting the wrong order. Thanks to this business, reduce risk, quality, cost of product recall.

- Tightly integrated warehouse – production – accounting – quality: on a foundation of data consistency. Every professional only enter once, but used for the whole system, help report reflect the reality at the same time. Thanks to accurate data, timely, leadership significantly shorten decision-making time.

- Flexible customized according to peculiarities in the chemical industry: ERP for chemical industry need to be flexible to customize according to the formula, process quality and production patterns, in batches of each business, at the same time easy to expand according to the scale. This helps to reduce training costs, increase the level of acceptance of the user.

- Appropriate accounting standards & legal in Vietnam: ERP for business in the chemical industry need to comply with accounting standards, tax and legal in Vietnam. At the same time meet the parallel financial reporting, and administration. Data are standardized on a system helps reduce the risk skewed, ready for inspection and audit.

- Unit deployment knowledgeable professional business English: to advise the right process, do not just install the software. As practice shows, advisory capacity as well as experience in the development of partner is often the factors that determine the degree of success of ERP project, even more important than the technology selected.

From the perspective of administration, operation, selection of ERP for business, industry chemicals need comes from the math operation and risk as well as development goals, long-term, not the level of “famous” of the software. ERP helps business to control inventory, production, costs, compliance with legal and decisions based on data. This makes platform management sustainable it rather depends on the feeling.

- ERP ngành thiết bị điện là gì? Giải pháp nào giúp DN quản trị toàn diện? – Lạc Việt ERP

- Solution Vietnam ERP for textile industry standards & compliance legal

- Lac Viet ERP in construction industry management intensive treatment for DN in Vietnam

- ERP ngành bán lẻ là gì? Giải pháp Lạc Việt ERP tối ưu vận hành & tăng trưởng bền vững

6. Solution Lac Viet ERP customized intensive for business chemicals

In the chemical industry the core problem is the lack of platform management deep enough to risk control, optimum operation long term. Lac Viet ERP is development-oriented ERP for chemical industry tied to the actual corporate governance in Vietnam. The solution supports synchronization from production, trade to accounting – financial and operating statements.

6.1. Solution overview Vietnam ERP for business chemicals

Lac Viet ERP is ERP solution comprehensive, flexible, user-friendly, designed based on the experience in implementing practical for many manufacturing enterprises in Vietnam. With the chemical industry, difference of LV ERP lies in the ability to customize the admin, instead of applying a model ERP “pre-packaged”.

Specifically, LV ERP respond well to:

- The enterprise chemical production batch (batch), there are many recipes and many levels of quality control.

- Commercial enterprise – distributor of chemicals, need to manage inventory by lot, shelf, vouchers and traceability.

Core value that LV ERP brings lies not in the number of subsystems, which in the connection throughout data from purchase – warehouse – manufacturing – accounting – reporting helps leaders see the paintings operate uniformly, instead of the “pieces of discrete data”.

6.2. The analysis highlights of LV ERP for chemicals

- Purchase order management materials & chemicals: ERP Systems help business plan buy keep abreast of the needs actual production. At the same time track full batch, expiry, supplier. Thanks to centralized data, business, reduce excess inventory, limiting the risks of material past due as well as more proactive ago fluctuations in input prices.

- Manage inventory by lot – term use – position: ERP Systems help businesses track inventory in detail according to each lot, shelf life and storage location instead of just managing the total. Thanks to early warning lot about to expire or inventory unusual business reduce safety risks, optimize working capital.

- Manage products & prices in batch: In the chemical industry, the cost of each batch of production can vary due to raw materials, operating conditions and attrition. ERP allows to keep track the price according to each batch to help businesses identify exactly cool how efficient cool would reduce profits to make timely adjustments.

- Financial accounting & reporting management: LV ERP related information, accounting data with the whole buying activity – wholesale – manufacturing – warehouse, help financial data always reflects the actual operation. Thanks to the report administrator updates in real time, leaders have the facility operating and decision-making faster, more accurate.

- Traceability & data analysis, multi-dimensional: ERP allows access to two way in each plot from raw materials to finished products, on the contrary. Thanks to that, the business quickly localize the event of quality, meet compliance requirements, improve credibility with customers and partners.

Lac Viet SureERP is ERP solutions in the chemical industry in accordance with the actual governance in Viet Nam, focusing on core business instead of complex technology. Support system, standardized management, control risk and improve operational efficiency, long-term for the business.

ERP for chemical industry has become the essential foundation to help business control risk, optimize costs, meet compliance requirements. When the data are focused on a unified system, businesses more active in the production, inventory, price and operating. Investment in ERP in the right direction to create a foundation governance, transparency and sustainable development in the long term.

- Lạc Việt ERP ngành thiết bị y tế quản trị vận hành đáp ứng chuẩn chất lượng & tuân thủ pháp lý

- Lạc Việt ERP cho ngành công nghiệp phụ trợ tối ưu quản trị sản xuất – chuỗi cung ứng cho DN Việt

- Lạc Việt ERP ngành cơ khí: Phân hệ & Giải pháp ERP phù hợp doanh nghiệp Việt

- ERP ngành thủy sản: Giải pháp & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP