ERP in construction industry is management solution overall for the business of construction according to the project, helping inter the core business on a unified platform. System support cost control, progress tracking, as well as syncing the data in real time. Through it, businesses improve operational efficiency and decision-making transparent and timely.

The article below Lac Viet will the construction business have a comprehensive view of the ERP for construction business, from concept, math fact to the role of ERP in improving the effective management and sustainable development.

1. ERP in construction industry what is?

1.1. The concept of ERP for construction business

ERP in construction industry is a systems management software focus, designed specifically to meet the particular operating of the business of construction according to the project/works. Instead of just recorded financial data or management personnel as the regular software, ERP construction focused on the entire lifecycle of a construction – since the cost estimate. Track actual spending until settlement, performance evaluation.

Other ERP manufacturing – commercial traditional ERP construction focuses on three array admin key:

- Management estimates – finalization: ERP for construction industry to help set up – track detailed estimates for each work, at the same time continuous comparison with the actual cost in the construction process. When the process is complete, data is collated to settle and determine the exact interest – hole of each project.

- Track expenses by category & construction phase: ERP for construction business help track expenses details on each item, the construction phase. Through it, businesses early detection of irregular expenses and timely adjustments in the deployment process.

- Control supplies – workers – machines in each work: ERP for construction industry helps to track, attach resources to each specific work. Through that business, limit losses, optimal coordination and ensure progress in the budget range.

In general, ERP for construction business is management platform operated concentration and contact information, not only accounting services or personnel. System to help control costs, the progress in real time to support the correct decision. Thereby improving efficiency, competitiveness of the business.

1.2. ERP in construction industry other what ERP usual?

Many people still understand ERP is just accounting software, financial, or personnel. In the construction industry, ERP is designed to fully managed each work with schedule, cost and own resources. Control does not strictly lead to the capital, reduced profitability. Below is the aggregated clarify ERP for construction business what other ERP typically:

| Criteria for comparison | ERP conventional (commercial production) | ERP in construction industry |

| Popular perception | Primarily serving the accounting, finance, hr | Platform management commissioning works |

| Management emphasis | Orders, inventory, production process | Projects/works throughout the lifecycle |

| Operational properties | Stable processes repeat | Each work is a case in private, many variables |

| Progress management | According to the production plan or delivery | According to the construction progress of the fact each work |

| Expense tracking | Synthesized according to the accounting period | Comparison of estimates – actual costs real time |

| Source of cost data | Mainly from internal accounting | Integrated from the scene, supplies, attendance, sub-contractors, |

| Discovered beyond the budget | Often late, after already incurred | Early warning when the cost of signs beyond estimation |

| By accounting for expenses | According to the group overall cost | According to works, items, stages, construction teams |

| Report interest – hole | Total business | Details to each work, each item |

| Value management | Service record, report | Decision support, control, profit project |

This table helps the reader quickly identify the core difference between ERP in construction industry, ERP usual. At the same time highlighting the value management practices of ERP specialized in the construction industry.

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Giải pháp Lạc Việt ERP cho khách sạn: 6 tính năng nâng cao hiệu quả vận hành

- ERP ngành in ấn là gì? Chuẩn hóa quy trình & tiêu chí lựa chọn ERP – Lạc Việt ERP

- ERP ngành nội thất: Chức năng & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP

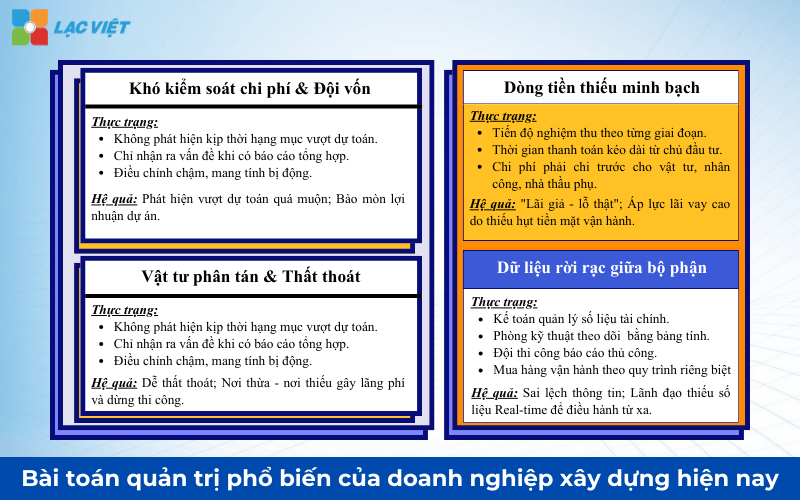

2. Problem management of common construction business today

In the construction industry, the biggest challenge is the effective management of many works in parallel in terms of cost fluctuations, advancing in complexity. When the lack of centralized data updated in real time enterprises to develop the issues of cost, schedule and cash flow.

2.1. Hard cost control team capital works

The cost of construction does not arise again, which arise constantly according to each day of construction, from materials and labor to machinery, the cost of rent in addition. However, in fact, many businesses still manage cost in the “post-test” – i.e., synthetic data after the construction was going on the last stage or complete. When cost is not timely updates:

- Command works't get out of items which are beyond estimation

- Leadership only discovered the problem when reporting month or quarter is synthetic

- The adjustment time is passive, less effective

Direct consequence is the profit margin of the project is worn right in the construction process, whether in contract revenue, the original can be evaluated as feasible.

2.2. Management consulting dispersion, loss

Supplies accounts for a large proportion in the total cost of works, but it is factors difficult to control most if the lack of system management focus. In fact, materials are usually dispersed in many works, warehouse temporarily, the or due to the construction teams self-management.

When there is no overall view:

- Business't have inventory reality in each work

- Supplies may be pending wrong purpose or losses difficult to control

- The status of the purchase excess in this work, while other works lacks regular

As a consequence, the cost of materials increased, while the construction schedule to be interrupted by the level transmitter is not timely. The lack of centralized management makes business lost control of the budget, effective use of supplies under each project.

2.3. Cash flow lack of transparency

A paradox popular in the construction industry is the business have interest on books, but always lack the cash to operate. The cause comes from the cash flow in construction depends closely on:

- Progress test in each stage

- Payment period lasted from the investor

- Cost to cost in advance for materials, labor, subcontractors

When income – expenses not tied to progress of fact, leadership is not forecast to be cash flow short term, lead to:

- Delay payments for suppliers, subcontractors

- To short-term loans with high cost

- Financial pressure even though the project on paper is still profitable

Businesses fall into a state of stress cash flow though the process still have interest on books. The lack of transparency and forecast cash flow-in-progress practice increases the financial risks, forcing companies to short-term loans with high costs to maintain operations.

2.4. Discrete data between the departments

In many construction business, each department uses a system or tool separately:

- Management accounting financial data

- Technical track progress using a spreadsheet

- Construction teams report from the school

- Buy restaurant operated by a separate process

Not having a source of data consistency that:

- Report to general craft, spending time errors

- Departments look the same works, but a different decision

- Leadership lack of timely data to the operator

In many businesses, building departments use the system – tool, separate from accounting, engineering to construction and purchase. The lack of source data consistency so that the information is fragmented, report to general craft.

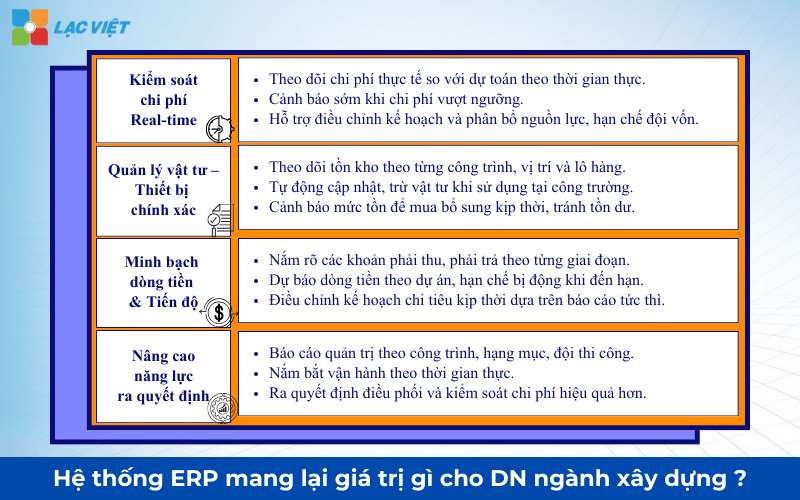

3. ERP in construction industry bring what value for business?

In the construction business, every project is a business unit independent of cost, own resources. ERP for business building to create data platform related information, updated in real-time to control operation and protect profits.

3.1. Cost control works in real-time

A core value of ERP for construction enterprises is to help management track actual costs against estimates almost immediately. When cost data is updated slowly discrete. The analysis control team, which had been delayed directly affect the profitability of the project.

ERP in construction industry recorded costs when incurred from investment – workers to the rental cost of machinery and continuous comparison with the original estimate. This helps the leader board early detection of fluctuations in cost, receive a warning when spend over the threshold and timely intervention to adjust the work schedule or resource coordination, avoid “discovered too late”.

3.2. Management consulting – precision equipment

Supplies – equipment is cost component in each of the works. But management investment efficiency is not simple if the data inventory, using not updated correctly according to each work, each position on the market.

Before applying ERP in construction industry, inventory supplies, often by each team to make updates via spreadsheet or recorded manually. This lead to deviations in inventory, wasted by buying excess or purchase and the cost team up when have to buy folding with higher prices.

ERP helps businesses:

- Track inventory reality in construction, location, warehouse, temporary or shipment.

- Automated except supplies when used at the school, avoiding overlap of material.

- Warning when the amount of supplies to the extent needed additional income, thanks to it to buy the right used enough to avoid reserves in excess.

From an operational point of view, this brings cost effective markedly reduce losses and avoid stop delay construction because of lack of supplies – common factors slowing progress.

3.3. Transparent cash flow & progress

Cash flow in construction, reflects the relationship between the cost spent, the cost of commitment and the money recovered from customers through the batch test. Many businesses fall into a state of “there is interest on paper but lack the cash in the account” because the proceeds to expenditures out not monitored in parallel.

ERP in construction industry connected financial data with the tempo test, the payment schedule allows business:

- Know the amount of actual money to be collected to pay in stages.

- Cash flow projections for each project, avoid the status of “passive” when a payment is due.

- Adjust the plan details the financial flexibility based on the signal report instant.

This ability is very important to business construction of many projects at the same time, by financial decisions quickly and definitely will reduce liquidity risk, support, maintain work progress.

3.4. Capacity decisions

One of the major obstacles when commissioning many works is to make decisions quickly, based on reliable data. In the environment have not yet digitized, the reports are usually synthesized from many different sources, take a lot of time and data may be false.

ERP helps to create management reports, multi-dimensional synthetic data according to:

- Works

- Category

- Construction teams

- Workers, equipment

This helps leaders understand the “big picture operation” immediately, instead of relying on the spreadsheet overlapping or outdated reports. Accurate data – timely help improve the quality of decision from coordinator human resources, optimal equipment to manage costs and reduce dependence on feeling.

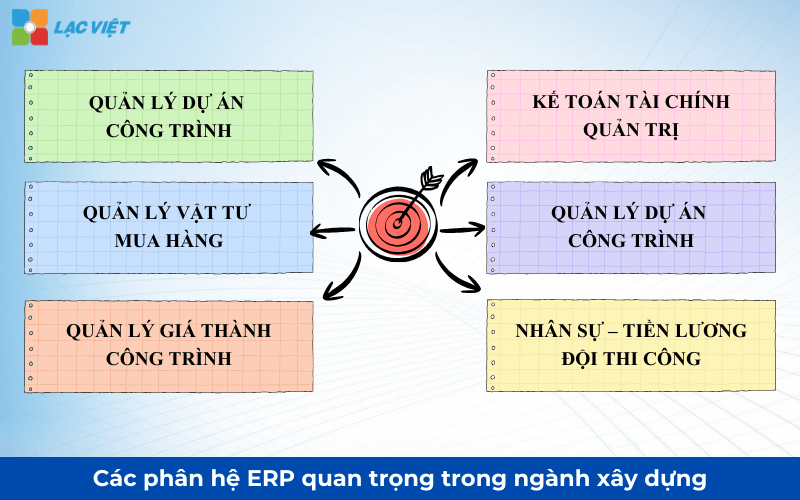

4. The analysis ERP important in the construction industry

In construction, each project is a cycle administration contact information between the many functions. ERP implementation discrete bring only effective locally, while ERP according to the system helps businesses better control decisions more accurate.

4.1 project Management – construction

Erp solution construction industry need to have the project manager works to help businesses not only track but also coordination resources flexibly and accurately.

- Set & keep track of estimates: This is not only a step recorded the expected cost, which is the foundation for comparison with the costs incurred fact.

- Progress management & volume of construction: Not all works are in progress are according to plan. ERP allows to link progress with cost, personnel. From that helps businesses know which items are delayed progress, construction teams are inefficient and can allocate resources accordingly.

Thanks to the project manager – public works business have a general update about the status of each work in real time. This foundation is important to control cost, schedule, coordinating resources effectively, limiting the risks that arise in the construction process.

4.2 Management and supplies – buy

In environmental construction materials – equipment are important sources directly affect the cost, progress. However, supplies are often scattered across multiple works, making inventory control and drain much difficulty.

- Suggestions buy in-progress works: this module is not merely to order; it mounts work schedule with the demands and supplies. This helps businesses avoid the purchase exceeds the actual demand or buying too late, causing the process to a screeching halt.

- Control import – export – conservation under each work: the System shows the details of supplies had been used in works which, for the category of what, how much inventory. This helps to reduce losses and avoid excess inventory, which occupies a large part of the working capital of the business.

Thanks to the management and supplies – buy business proactive planning of supply according to the construction schedule, tightly controlled consumable supplies under each project. Thereby, costs are better controlled, limiting the disruption of construction and reduce the pressure of working capital.

4.3 Manage the cost of the project

Know the price and the fact of each work, each item is the key to building business maintain sustainable profitability. This module helps to:

- Set the cost according to items: Instead of synthetic crafts, ERP automatically aggregate costs incurred related to each item to help businesses understand costs at a detailed level.

- Cause analysis team price difference: When the actual cost exceeds the estimate, the system supports root cause analysis, thereby making the recommendations or warnings before problems become serious.

Management subsystem price works to help businesses grasp the exact actual cost in each of these categories, compared with the estimate. Thanks to that, the business soon discovered the cause disparity, proactive adjustments to protect the profit margin of the process.

4.4 financial accounting – management accounting

In any business, accounting is the “common language” to evaluate business efficiency. However, erp for construction enterprises need more than one accounting software simple:

- Accounted for by the works: Instead of focusing on account of the total, accounting as the process helps to analyze the cost – profit each project. From that project, which really lucrative project, which put pressure cash flow.

- Appropriate accounting standards in Vietnam (VAS): this helps the business not only manage internal efficiency but also comply with reporting standards as prescribed, avoid legal risks.

Analysis financial accounting – management accounting in ERP in construction industry allows accounted for effective analysis in each work, rather than just at the level of synthesis. Thanks to compliance with accounting standards in Vietnam, medium business, internal control better, just ensure transparency, legal compliance.

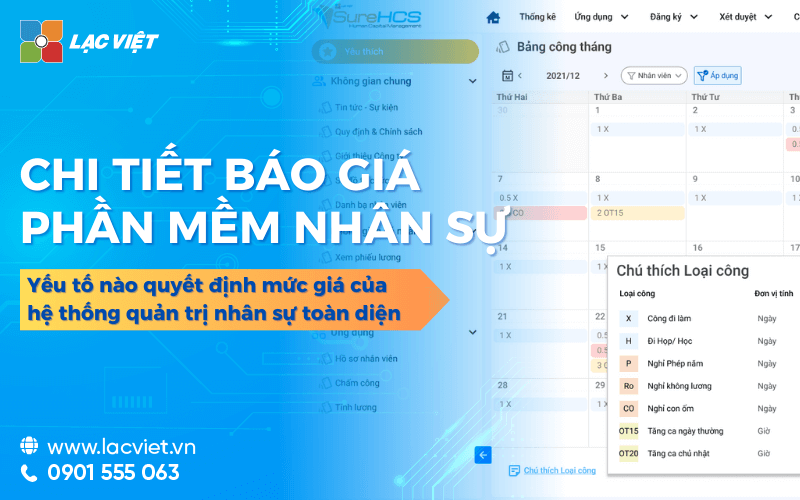

4.5 Personnel – wage construction teams

Hr is the cost of big Monday following supplies for the most part works. This module helps businesses:

- Calculate salary according to the work & shift: Instead paid by the month overall, the system allows calculation of salary as per the process, according to shift work, to help businesses clearly see the cost and the fact associated with the construction schedule.

- Track labor productivity: the System recorded yield data from which analysis to assess the effectiveness of construction teams, to help adjust the plan personnel or proper training.

The hr – wage construction teams to help businesses mounting costs directly to each work, work shift. At the same time, productivity data is continuously monitored, support effective evaluation team construction and optimized workforce planning.

4.6 reports, analysis & BI

This module not only the “display data on the screen”. It is the core of the sensor data into decision actual:

- Progress report – cost – benefit: Provides leadership, overall look, in detail, at the same time about the status of the project helps the comparison between planned and actual real-time.

- Dashboard visualization: An image visually easy-to-understand data help the leader to catch problems faster than reading hundreds of pages of reports.

The reports analysis & BI helps transfer data operation of management information valuable. Through the report, dashboard, intuitive leadership quickly capture schedule, cost and profit to timely decisions.

- ERP ngành thiết bị điện là gì? Giải pháp nào giúp DN quản trị toàn diện? – Lạc Việt ERP

- Solution Vietnam ERP for textile industry standards & compliance legal

- System LV ERP for chemical industry: solutions & selection criteria ERP suitable for business

- ERP ngành bán lẻ là gì? Giải pháp Lạc Việt ERP tối ưu vận hành & tăng trưởng bền vững

5. Lac Viet ERP – ERP solutions for the construction industry

In the construction industry, points of congestion, the largest located at the lack of management system operation in real time. So business days as priority ERP in construction industry specialized for construction. ERP of Lac Viet is developed according to this orientation.

5.1 Lac Viet ERP solve the problem what to construction business?

From the perspective operation management are the core of the construction business is not just “software”, which is how to connect throughout data from estimation – construction – finance – hr, instead of each department to manage an array separately.

LV ERP helps business build solved at the same time three big problems:

- Cost control works as soon as they arise: ERP recorded the cost of supplies – workers – machines in each work item, the construction phase. Thanks to that, the leadership track disparity estimation – reality almost instantly, not wait for late report states.

- Transparent cash flow associated with the progress test: LV ERP link cost, the volume of completed and payment plan according to each work. Help business forecasts, actively operating cash flow to avoid the process with interest, but lack of cash to operate.

- Consistency data for the entire organization: When accounting, engineering, purchasing, and personnel work together on a platform, the data no longer be out of phase. This helps the decision governance based on “a reliable data sources only”, instead of multiple tables Excel different.

LV ERP not only is ERP for construction business that is operating platform works based on the data.

5.2 Advantages of LV ERP for construction industry

Not all ERP solutions are suitable for the construction business in Vietnam. LV ERP is appreciated by the advantages fastened with actual operation:

- Deploy according to the actual demand, highly customizable: LV ERP pattern support on-premise, meet the requirements of data security at the same time flexible to customize according to the scale models of construction, the management of each business, instead of forcing companies to change the process to fit the software.

- In accordance with enterprise compliance standards accounting VAS: accounting System in SureERP support accounted for by the works of the meet at the same time requires accounting financial management. Thanks to that, medium business, internal control effectiveness, while ensuring compliance with legal regulations.

- Reporting system fast, accurate, multi – dimensional: SureERP provide reports according to multiple perspectives: the process, item, team, construction, cost, profit.

The greatest value of this advantage is not located in the “beautiful or multi chart”, which in the leader grasped the situation your real business to timely decisions.

5.3 any Business should choose LV ERP?

From experience in implementing real SureERP particularly suitable for:

- Building contractor, EPC contractor: Need to control cost, schedule and cash flow across multiple projects at the same time

- Construction business civil – industrial: There are management requirements detailed in works items

- Business management many projects in parallel: Where the slow data or false statements can cause big risk financially, reputation

With this business, investing in an ERP solution, the construction industry specifically as LV ERP not only is the investment for IT, which is the investment for capacity management, sustainable growth.

LV ERP is ERP solution due to Lac Viet developed to help businesses build, standardized management and control operate in real time. With experience deployment for enterprises, LV ERP is oriented to the long-term in the expansion process and convert the number. Detailed information about the solution may refer to: https://erp.lacviet.vn/

In the context of cost fluctuations in several categories arises, ERP in construction industry in-depth support track actual versus estimates, limiting the team capital, slow progress. The transparent data commissioning help leaders timely decisions, improve the efficiency of project management. This is important platform for enterprises to build standardized operation and sustainable development.

- Lạc Việt ERP ngành thiết bị y tế quản trị vận hành đáp ứng chuẩn chất lượng & tuân thủ pháp lý

- Lạc Việt ERP cho ngành công nghiệp phụ trợ tối ưu quản trị sản xuất – chuỗi cung ứng cho DN Việt

- Lạc Việt ERP ngành cơ khí: Phân hệ & Giải pháp ERP phù hợp doanh nghiệp Việt

- ERP ngành thủy sản: Giải pháp & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP