According to statistics of the Ministry of Industry and Trade, energy now accounts for about 15% – 30% of the total operating costs in production even up to 50% off in the fields such as metallurgy, textile, chemical. At the same time, the requirements from markets international partners are shifting in the direction of “more green”: the product not just quality but also to prove to be the low-emission production processes, energy-saving, environment-friendly.

It is in this context, building management system, energy is no longer choose voluntary that are necessities to survive development.

This article Lac Viet Computing will help the business get perspective overview of system energy management: from concept, basic structure to how to implement efficiency in actual operation.

1. Management system what is energy?

System energy management (Energy Management System – EnMS) is a set of policies, processes, tools, designed to help businesses to control, monitor, improve energy usage in a systematic way.

If for business as a living organism, the system energy management is the brain controls the use of “blood” energy star for efficiency, avoid waste. Instead of depending on experience or reaction when electric bill spike, the business will have a tracking system clearly helps:

- Know the energy is being consumed now, with the performance out why

- Early detection of these point drain unreasonable or ineffective

- Make decisions based on actual data instead of feeling

Any business should apply?

In fact, every type of business can, and should, apply system power management, but particularly suited to:

- Business that energy costs account for a high proportion (manufacturing, construction, logistics)

- Business has many large-scale factories, equipment, continuous operation

- Businesses that are in the roadmap image-building “green” to join the global supply chain

- Businesses are looking for ways to standardize operation to improve efficiency management

Even the small and medium enterprises can also start with these simple steps such as tracking the power consumption according to the departments, performance reviews, equipment or plan replace outdated technology, causing wasted electricity.

- Software energy monitoring operational efficiency and emission reduction, sustainable

- Software energy management digitized efficient energy consumption for business

- Management what is energy? Processes, policies, effective management for business

- Everything about iso 50001 standard in energy management for modern business

2. Practical benefits of the system energy management for business

A system of energy management EnMS not only help control the consumption of electricity or fuel, but also bring more comprehensive benefits from finance to strategy development. Below is the outstanding value that the business can achieve when applied to EnMS all the way.

2.1 Reduction of 5-20% energy costs per year

According to the report UNIDO in the year 2023, the business development system EnMS can save an average of from 5 to 20% in energy costs in the first year. Rate this savings come from:

- Eliminate wasted energy potential

- Optimal operating procedures

- Adjust production schedule fit the frame hours, low consumption points

For example, A plastic factory in Binh Duong, after implementing the EnMS have discovered furnaces operate beyond capacity at peak hours. After adjustment, business up to be more than 300 million/year on electricity bills.

2.2 Increase operational efficiency, prolonged equipment life

System EnMS helps enterprises monitor the operation of the device consumption such as air conditioning, industrial air compressor, water pump,... maintenance at the right time, operate according to the standard save not only energy saving, but also:

- Reduction in breakdowns surprise

- Prolong use of equipment

- Reduce maintenance costs, replacement

2.3 Reducing emissions CO₂ support the development goals sustainable Net Zero

Any reduction in energy would also entail a reduction in emissions of CO₂. With system EnMS, businesses can:

- Precision measuring emission levels

- Planning report ESG transparency

- Step by step building roadmap Net Zero suit

Especially important when customers, investors or partners abroad increasingly interested in environmental commitment in the supply chain.

2.4 increase the reputation and cooperation opportunities with international customers, partners ESG

Proven ability to manage energy not only help business save cost, but also:

- Increase competition in bidding or call capital

- Meet the standard requirements on ESG from foreign partners

- Building images modern enterprise, responsibility and transparency

With respect to the business directory, this can be important advantages to reach the demanding market such as EU, America, Japan...

2.5 Standardized internal processes to help businesses operate, streamlined transparent

A system EnMS not just technical solutions, but also the opportunity to:

- Reorder processes operating in the optimum direction

- Standardized operation between the parts

- Set savings culture, thinking, continuous improvement

These factors help the business operate more stable, easy to adapt when scaling or conversion model manufacturing business.

3. The core components of a system EnMS effective

To system energy management bring long-term efficiency, businesses need to build on a foundation of solid structure, not enough only technically but also flexible to fit particular operating. A system EnMS standard efficiency often includes 5 following components:

- Energy policy are clearly commitment from leadership: energy policy is a formal statement of business on the use of energy-efficient, the orient express strategy commitment from leadership. When real leadership backing, all parts will be motivated to adhere to proactively improve.

- Reviews current consumption determine the points that need improvement: Business should conduct an overall assessment of the regional energy use from production line, lighting systems, air conditioning to the auxiliary equipment. The analysis of this data helps determine where the point of consumption, where is the area to waste, now is where there is the potential to improve quickly.

- Set indicators to measure energy performance (EnPIs): The index EnPIs help business track performance, energy use over time. Some simple examples: the Number of kWh of electricity consumption per ton of product output; the Amount of fuel used per kilometer shipping; energy Costs on each order completed. Thanks to these indicators, business easily evaluate the progress of the effectiveness of measures to save energy has deployed.

- Goal setting, action plan and monitoring system: System EnMS can't succeed without goals, plan of action clear. These goals need to be set up according to the principles of SMART (specific, measurable, achievable, realistic and have a time limit). At the same time, there should be tools to monitor progress periodically to ensure that all actions are going in the right direction to create real improvement.

- Continuous improvement according to the PDCA cycle (Plan – Do – Check – Act): PDCA is the principle operating core in every system of modern management. This cycle helps business does not fall into the status of “make available” without actually turn the energy saving of a part in culture operated.

4. Standard on system energy management

When it comes to energy management in a basically, ISO 50001 is the international standard that is widely recognized is considered the main framework to help businesses build operate and continually improve the management system of his energy. Besides, the methods of measurement of emissions according to the GHG Protocol also plays essential role in the follow-transparency, effective, energy-saving emission reduction.

4.1. ISO 50001 – System energy management standard international

ISO 50001:2018 is standard is issued by Organizing international standardization (ISO) helps organizations build management system, comprehensive energy from policy-making, goal setting, to measure the effectiveness of energy use.

This standard applies the PDCA cycle (Plan – Do – Check – Act) to:

- Use planning for energy efficiency, reducing waste

- Implementing control measures, monitoring

- Measurement rate energy consumption

- Process improvement based on real data

Strengths of ISO 50001 is the ability to integrate with other standards such as ISO 9001 (quality management) ISO 14001 (environmental management) to help businesses synchronise the system of internal management, reduce operating costs.

Achieving ISO 50001 certification not required but is a big advantage in demonstrating commitment to the environment with partners, customers and investors. At the same time, this is also the criteria to be many multi-national corporations, international supply chain priority when choosing partners.

4.2. GHG Protocol – Standard measurement report greenhouse gas emissions

Besides the management of energy consumption, businesses today must also track the amount of greenhouse gas (GHG) emissions from production activities, operating particularly in the field have emission levels as large as manufacturing, transport, processing...

GHG Protocol (Greenhouse Gas Protocol) is the standard global is widely applied to calculate the reported emissions of CO₂ and other greenhouse gases other. Divide into 3 scope (scope):

- Scope 1: emissions directly from the operation of the business (e.g., burning fuel in the boiler)

- Scope 2: emissions indirectly from the use of electricity, steam or energy purchased from outside

- Scope 3: emissions indirectly from the supply chain, shipping, products sold, garbage disposal, etc.

Applying GHG Protocol that helps businesses:

- Calculate emissions accurate system

- Report builder sustainable development according to international standards

- Meet the requirements of transparency from financial institutions, global partners

4.3. The standard tool to support other

In addition to the two standard frame on the business may refer to the technical guidance and support tools from:

- UNIDO (development Organization, the united Nations industrial): Provides diagnostic tool, instructions implementing EnMS for SMEs business

- ASEAN Energy Management Scheme (AEMAS): System support deploy EnMS in the southeast Asian country

- Software EMS (Energy Management Software): automation, monitoring, analysis, optimize energy use

5. Process system deployment, energy management in business

The deployment of the system energy management is not required to start with high-tech equipment or large investments. It is important that businesses need a clear process, take route in accordance with the scale practical ability. Here are 5 steps to deploy the standard that any business can also apply:

Step 1: Commitment from leadership

The success of any management system, how special is energy management depends on the level of commitment of the leader board. This is not only expressed in words that must be concretized in action:

- Enact energy policy clear

- Budget level to deploy the initial operation

- Assigned specific responsibilities for departments in charge

Benefits that businesses get:

- Create a solid foundation for the whole system

- Encourage the spirit of initiative from the operating departments

- Avoid operation system, discrete, teen, teen-oriented

Step 2: Assessment of energy consumption

Before improvement, business need to know are energy consumption, where, how. This stage includes:

- Collect data from electric bills, reported operating

- Check the device power consumption/fuel main

- Analysis area signs, waste or unreasonable

The goal is to identify the “hot spots” – areas or equipment account for a large proportion of total consumption to priority handling ago.

Benefits:

- Have realistic look, instead of judgment, feelings

- Given saving measures specific to real situation

- Avoid investment, lack of effective

Illustrative example: A business logistics discovered that nearly 40% of the fuel truck is wasted due to waiting loading and unloading lasts from which they held back shifts, online delivery for optimal operation.

Step 3: build system in accordance with enterprise scale

Based on the evaluation results, the business will proceed with system design, energy management in accordance with the scale, target industry of its own, including:

- The target building energy saving in each department

- Set indicators to measure energy performance (for example, kWh/ton of product)

- Action plan details (changing the equipment, adjust the operation schedule, training...)

Small and medium enterprises do not need complex pattern. Just a few tables simple tracking on Excel or Google Sheet combined with internal regulations, schedules periodic inspection can also create significantly improved.

Benefits:

- Cost savings initial deployment

- Flexible adjusted according to each stage of development

- Easy to maintain expand when necessary

Step 4: Training personnel commissioning

No system is effective if people do not understand, do not actively participate. In this step, the business need:

- Basic training for the used parts and equipment more energy

- Guide how to track only number of recorded feedback unusual

- Commissioning the system in small range to test the effectiveness

Benefits:

- Raise awareness internally, the word “energy management” becomes “savings culture”

- Reduce risks when deploying the tea

- The way to improve according to real feedback

For example, An apparel company in Bac Ninh has trained leader makes checking the sewing machine when not in operation. In just 1 month, the shutdown properly when you stay between ca has helped save more than 7% of the cost of electricity.

Step 5: assess, adjust and certification (if required)

After the time of commissioning, the business should conduct an assessment of the entire system:

- Compare actual results with the initial goal

- Recorded the score achieved and not yet achieved

- Update the plan or adjust the measurements if needed

If the business wishes to achieve ISO 50001 certification, this is the time invited the independent evaluation to test the system. However, even without the need for certification, maintaining periodic review is still important elements of the system of continuous improvement.

Benefits:

- Ensure the system works efficiently, do not stop at the “movement”

- To facilitate internal communication, diplomatic efforts greening

- Get ready for the test requirements from partners or authorities

Process system deployment, energy management is not too complicated if the business has clear roadmap, in accordance with practicality. Each step towards practical value: from cost reduction, optimal equipment to build credibility.

6. System, energy management and Carbon emission reduction of Lac Viet

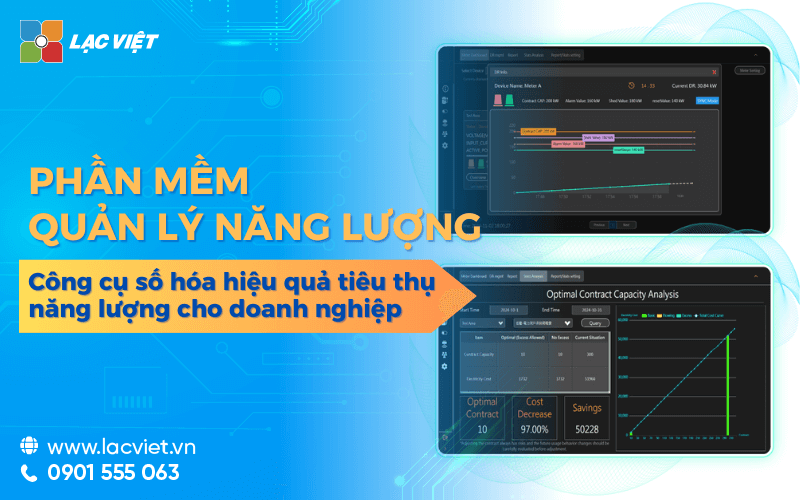

Vietnam has developed solutions to Manage energy and Reduce Carbon emissions in order to support business step by step control, efficient energy use towards commissioning sustainable. This is a management platform integrated application technology of modern helps enterprises monitor, evaluate, optimize energy performance in an active way.

Solution of Lac Viet provide the ability to monitor energy consumption in real-time with high accuracy through sensor systems, measuring equipment, and center console. Collected data visually displayed on the software platform helps businesses:

- Track the status of energy consumption at each workshop, necklaces, departments

- Receive alerts when it detects usage exceeds the threshold, drain the unusual

- Trend analysis using shift/crew day/week/month to find out the time consumption and potential savings

- The system is designed in accordance with the standard energy management, environmental top as: ISO 50001, GHG Protocol

- Tool set for emissions reporting periodically automatically help businesses calculate the emissions of CO₂ and other greenhouse gases corresponding to each operation, production, operation. Set goals to reduce emissions by year, by unit of product. Track progress in implementing environmental goals in a transparent way visually

Are you looking for solutions to save energy costs and reduce emissions in a smart way, it?

- Sign up to receive a free consultation from expert energy Club Vietnam

- Or download the documentation to deploy the solution at: https://lacviet.vn/giai-phap-quan-ly-nang-luong-va-giam-phat-thai-carbon

7. Frequently asked questions (FAQ)

1. Small businesses should apply system power management not?

The answer is yes – and it should begin as soon as possible. Many businesses, SMEs accounted for the proportion of energy costs are very high compared to the revenue. Just track adjustable few simple activities such as time turn on the device, the production process, changes in routine operation... well enough to save a few million to hundreds of millions of dollars each year.

EnMS does not require big investment, which is important to change the thinking methods of scientific management.

2. How long does it take to deploy a system of energy management?

Deployment time depends on the scale level of complexity of business operations. With small and medium enterprises, exposing the underlying process can be completed in 2-4 months. Big business or have more workshops may need 6-12 months to standardize operational efficiency.

However, businesses can deploy in small steps according to the region or necklaces ago – then replicated.

3. There is the need for software or special equipment not?

Not necessarily invest in software or modern sensor right from the start. Many businesses start with the follow-up table simple (Excel, form, paper) in combination with internal guidelines. If conditions demand extended enterprise can be upgraded by software, energy management, measurement equipment, auto dashboard data...

It is important that the system must be consistent with the possibility of existing resources, not as modern as possible.

4. Need ISO certification 50001 not?

The application of the system EnMS are not required to have the certification of ISO 50001 but if businesses want to:

- Enhance credibility when working with international partners

- Meet the requirements audit ESG

- Or participate in the tender green projects

... the ISO 50001 certification will be a huge advantage.

Even when not qualified certificate, the deployment of EnMS standards still brings nearly the full benefits of commissioning, saving emission.

In a world where operating costs are increasingly expensive and the environmental standards increasingly stringent, the management of energy efficiency is no longer the option that is the condition of survival for businesses to maintain profitability, empowering meet expectations from the market as well as the community. Whether your business activities in the field of manufacturing, trading or services, whether small or large scale, the deployment of EnMS properly always bring specific value both financial and brand image.