Manage a production process with dozens of stages, hundreds of devices and thousands of employees is a challenge not simple for the business. Management software production process comprehensive operation seamless, is the solution to support business planning, progress tracking, production, check product quality,...

In this article Lac Viet Computing will exploit these aspects revolve around tool management, production from that facility to the business search is the most suitable project.

1. Problem of managing the production process, causing concern for enterprises

Report of TMF Group for see, one of the big challenge for manufacturing enterprises in Vietnam is the lack of conversion of in process management, leading to inefficiency and increased costs.

According to a recent survey Newsto 61.4% of businesses in the field of production and processing encounter more difficulties in production and business. These difficulties primarily revolves around controlling costs, managing resources and maintaining quality of products.

In general, most of the business Vietnam manufacturing are faced with challenge after, special issue becomes more urgent when the switch number becomes essential trend:

- Production process passive, discrete, old main is the cause of defective product batch, the output quality is poor.

- Report production process manually with the software discrete or even in paper, hand-written text. Data scatter, causing delays in decision-making, take the time in the synthesis report, and do not understand the performance of the whole process.

- 't capture the defective product at every stage, why the error causing the investigation causes errors prolonged stagnation production progress and slow to respond to customers.

- Departments discrete, lack of coordination, information is not synchronized, consistent, to cause delay, interruption in the production process of the business.

Management systems, automated processes, comprehensive privacy solution is removing all the difficulties of manufacturing enterprises at present. Only with management software production process, All-in-one, businesses can capture information about the progress of production, the calculation is workload specific and capture the timely correct the phase error.

2. Learn management software production process

2.1 management software production process, what is?

Management software production process is tools business support optimization of production activities from the stage of planning, materials management, progress tracking for up to control the product quality.

Tool allows the creation process, automatic production system established through the inextricable link between the relevant departments such as accounting, sales, purchase, inventory, human resources, planning and production. All connections in a database single comprehensive suite for business.

2.2 the Role of software process management in production

Research from LNS Research shows the software application management process can reduce up to 25% off production time through streamlined processes.

Management software, manufacturing ERP is integrated with many outstanding features to support business optimized and streamlined the entire production process. In addition, management tools, the production process also brings the following benefits:

- Dark streamlined the entire production process: By synthesis, track reports, data in the workflow, the software proposes to remove the step excess to poor performance.

- Balance the load of work: Allocate work in reasonable detail for each equipment, staff, limiting overload or lack of jobs.

- Coordination between the parts: With the support of the management software, manufacturing processes, all parts in business from engineers and workers to offices such as accounting, business, sales,...all can be track process status, warehouse, production coordination, smooth on 1 single platform.

- Reduce the cost of production & operating: Support business considerations and resource distribution, human resources and production equipment, reasonable, minimize the wastage. In addition, the software also has features expected raw material, accurate, allow businesses to optimize costs.

- Improve the quality of products: All products are monitored from the moment of selection of raw materials until finished products, ensure to meet all the quality requirements, and significantly reduced the error rate.

- Sync and data management focus: Data on production planning, inventory, purchasing, shipping, management, product quality, or even finance are synchronized and stored to focus on 1 single platform, avoiding the inconsistent information. This allows all members to have a vision about the situation of production, easily access, manage, and analyze data.

3. Top 5 software to manage the production process, the most professional

Reference list 5 application process management best production market.

- Management software, manufacturing processes, LV-DX Dynamic Workflow

- Management software, manufacturing ERP BRAVO

- Management tool production Faceworks

- Software process management, production and sales for free VNSolution

- Production management software overall Sinnova

3.1 management software, manufacturing processes, LV-DX Dynamic Workflow

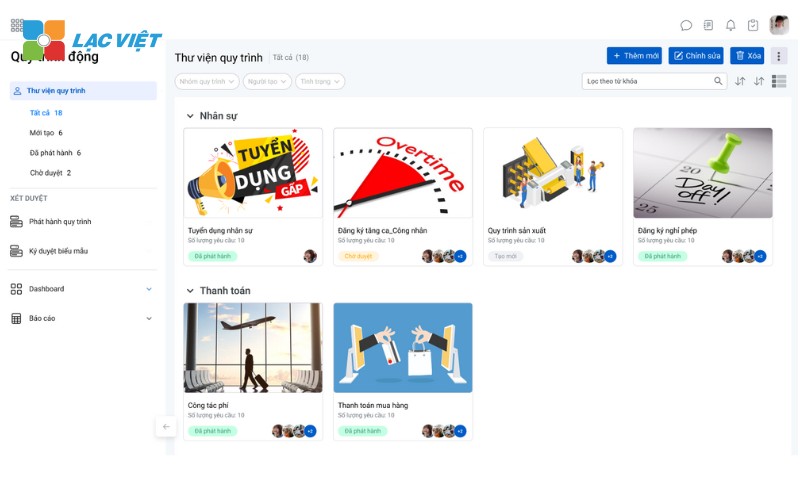

LV-DX Dynamic Workflow is a system process management business overall, with the ability to customize flexible software can optimize production activities of diverse business areas.

In particular, only with a single platform, businesses can link the production process multi-room board from the stage production planning, forecast consumption, planning, raw materials, management team, employees and supply chain.

Is one of the pioneering technology, Vietnam welcomes top trend solution integration tools Chatbot AI on LV-DX Dynamic Workflow supports business analysis prosecuted information, analysis, report and predict the production precision.

Feature highlights

- Definitions of the form input to stored information, raw materials, personnel, or the number of products.

- Set the standard work in each step production procedure and the time limit for each stage of work.

- Automatically set conditions of transfer steps, delivered at the production stage to the next.

- Tracking and monitoring the progress of each step in the production process in real time. Understand what stage has completed/failed, cause of failure and responsible person.

Applicable objects

LV-DX Dynamic Workflow suited to both large enterprises, small and medium belonging to all the different areas.

3.2 management software, manufacturing ERP BRAVO

Software Bravo featured by the ability to cover the entire production process, from production management, declaration management and BOMBS, the materials, updates & progress tracking, production management, importing and exporting exist workshop, control consumable supplies...

Not only stop at that, management software, manufacturing processes, Bravo also allows business statistics output according to the production plan/order production and commissioning process, to test/evaluate the product quality, through which control the quality of each products before distribution to consumers.

However, the biggest limitation of Bravo is only offered as a package with a high price. This makes it difficult for small businesses, especially businesses, there is no system administration complete in-process approach and deploy software.

Feature highlights

- Declaration norm of raw materials for each stage, products or orders.

- Production scheduling based on demand, allows businesses to adjust (add/reduce) production plan if incurred fluctuations.

- Perform production and update the output produced by each stage, production order or production plan.

- Support the calculation and payment of materials and production according to the production orders, or orders, automatic machining.

Applicable objects

In accordance with the large-scale enterprise, montreal, production models varied, financial resources and strong.

3.3 management tool manufacturing ERP Faceworks

Management software production process Faceworks have the ability to customize in accordance with the requirements of any type of business such as production, wood industry, electronics manufacturing, textile manufacturing, packaging production,...

App allows businesses to manage the details of raw materials, inventory or orders, products,... without need to change any process management.

Feature highlights

- Allows management and storage of diverse kinds of data related to production processes, such as norms of materials, labor, production requirements, production orders, planned execution and data about the stock, such as export, import, inventory, location, commodity,...

- Automatically calculated plan from alerts minimum of inventory.

- Provides reports about the level of productivity each process, progress made, quality products in the form of graphs.

Applicable objects

In accordance with the business corporations.

3.4 software process management, production and sales for free VNSolution

System VNSolution is known for its ability to build process self-contained production from when setting up order production needs to plan production plan and calculate the likely supply of raw materials in stock, the ability to set the level of raw materials for each stage of production, price calculation, the depreciation rate materials to track the sales process.

In particular, to support the small business approaches management software, manufacturing processes, VNSolution also provides version free use. However, non-restricted quite a lot about the tool works and the ability to store information, so businesses need to consider if you want to use long term.

Feature highlights

- Set of requirements for goods from the source forecast (Forecast) and the order of the customer (Sales Order) to create demand for goods need to produce at certain times.

- Create the production orders based on the number of material goods need production.

- Supports calculate requirements for materials based on the production plan.

Applicable objects

Suitable with all types of businesses.

3.5 production Management software overall Sinnova

However, as a software process management overall, Sinnova can still make a good role management production through the established process (routing), management planning, dispatching, supply of raw materials and production statistics.

Besides, the software Sinnova also business support status tracking, inventory overview, from the arrangement of space, equipment and machinery to process import – export goods and the management of inventory.

Feature highlights

- Supports automatic scheduling of production, plans to use the machine, resources, raw materials according to the production process.

- Show production planning overview and details on each product visually through the gantt chart.

- Support allocation, production planning detailed stages, according to the date and control of stock produced according to the requirement of supply of raw materials.

- Track details output according to each day work, shift work, stage, production orders.

4. Selection criteria management software production process standard

Full features responsive production process

The system should fully meet the required production management of the business, including process management and scheduling, production management, raw materials, finished products, warehouse management, quality management, progress tracking and reporting the progress of production.

The ability to integrate multi-platform

To create favorable conditions for the connected devices, IoT, artificial intelligence AI, software management... in the task of optimizing the process and improving work performance, management tools, production processes need to have the ability to integrate multi-platform.

Interface optimized user experience

The nature of work produced, including many position different from the leadership, management to construction, the design management software, production processes need to be optimized anyone can use effectively.

Customizable flexible processes according to specific production

Depending on each industry manufacturing, business will have different needs in establishing operating procedures. This requires a management tool production can flexibly customize the process to meet all fields.

Costs in line with business budget

Business should consider the following expenses: deployment, training, maintenance, and upgrade management system, production process, to find the most suitable option.

Because of the nature of complex manufacturing processes like effective, optimum cost, it requires to have the help of a support tool automatically. By considering a thorough selection criteria and 5 management software production process comprehensive Lac offers, business process management professional production, cost savings and improve the quality of products/services.

CONTACT INFORMATION:

- Lac Viet Computing Corporation

- Hotline: 0901 555 063 | (+84.28) 3842 3333

- Email: info@lacviet.vn – Website: https://lacviet.vn

- Headquarters: 23 Nguyen Thi Huynh, P. 8, Q. Phu Nhuan, Ho Chi Minh city