The drain excessive energy leaks silently or device to operate less efficiently, which can lead to losses of hundreds of millions of dollars each year that the business is not easy to get out. That's why system power monitoring is becoming one of the solutions essential to help businesses proactively control consumption, optimal cost, and step by step achieve the international standards on emissions, sustainable.

The article below Lac Viet will help the business understand the monitoring system, what is energy, how it works, the benefits practices bring, as well as a roadmap for effective implementation to not only save energy but also create a solid foundation for the strategic transformation of green certification carbon future.

1. System monitoring what is energy?

System power monitoring is a technology solution designed to monitor, analyze and control energy consumption of the enterprise in an automatic way, continuous. Other measuring devices conventional power only display indicators consumption overall, this system allows to collect data in real time at each point of consumption from which support the management decisions that optimize operation and reduce the cost to the sustainable development goals.

1.1. The main components of the monitoring system energy

A system power monitoring include:

- Measuring equipment, sensor: installed at the area power consumption as machinery, production line, lighting system, air conditioning, pumps... The sensor can measure the power, water flow, temperature, pressure and even the exhaust gas if need be integrated.

- The data transmission (Gateway or IoT Module): Receive signal from the sensor transmitted to the central system over a network connection.

- Monitoring software energy: Where data are analysis, synthesis, displayed in the form of panel (dashboard), chart, report. The manager can view directly the situation of energy consumption by the hour, by region, by device.

1.2. Difference with measuring system, conventional power

Measuring system electric transmission system provides only the total electricity consumption by month, usually do not specify the source to waste. Meanwhile, the monitoring system energy:

- Detailed analysis of power consumption in real time, each device

- Early detection of device status, operation process, power consumption unusual

- Help put out the warning, solutions to overcome timely instead of just “recorded” figure after the loss has occurred

1.3. Why this tool is mandatory with the business aim to stock only carbon or ISO 50001?

The certificate of emission energy management as GHG ProtocolPAS 2060, or ISO 50001 require businesses to have the system track, measure, report, energy consumption correctly transparency.

The systematic monitoring of power:

- Is clear evidence for commitment to reduce emissions indirect (Scope 2)

- Help construction business plan of action specific to each workshop or device

- Increase transparency in report ESG – an important factor when called capital or participate in the supply chain green

- Hydrogen what is green? New direction for the business sustainable production

- GHG Protocol what is? Implementation guide standard measurement international for business

- ISO 14064 is what? Detailed instructions building system standards credits carbon international

- Products what is green? Examples of green products in Vietnam

2. Monitoring system energy how it works?

One of the strengths of the monitoring system modern energy is the ability to fully automate the process of collecting, processing, alert data to help businesses save time and reduce errors.

2.1. Mechanisms to collect data automatically from the device power consumption

- The sensor energy meter is installed at the point of consumption, such as electrical cabinets, machinery, lighting systems...

- Data from these sensors is transmitted over the network (LAN, Wi-Fi or 4G) on the central processor or software platform cloud

- The system can update the data in cycles of a few seconds or minutes, allows track the status consumption in real time

A manufacturing enterprise can know exactly each plastic injection molding machine consumption how much electricity during a work shift, instead of just looking invoice your total end of the month.

2.2. Analysis – alerts – intelligent reports

The system not only record data, but also:

- Trend analysis of consumption over time, according to the region to detect the point of consumption unusual

- Warning, operator error, or leakage energy, for example such as machine running the wrong hour, turn 24/24 though not necessary

- Automatically export reports by day, week, month, according to the form available service, internal audit or inspection from the outside

Managers don't need to check manually that still hold to be “healthy energy” of the whole plant.

2.3. Integrated with the ERP system, management software, emissions

A big advantage of the software, monitoring today's energy is the ability to integrate with ecosystem current operation of the business, including:

- ERP software, accounting software: sync energy data with production data and financial

- Software, environmental management (EMS): support reporting emissions Scope 2 standard GHG Protocol

- Software ESG or rating system credits carbon: automatically extract data demonstrate for the report published emission

3. What features are needed when choosing the software/system power monitoring

When choosing the software or system, energy monitoring business should not just stop at the ability to measure power consumption. An effective solution needs to help businesses track, analyze and act on data, thereby creating value, save, support for emissions reporting transparency.

Here are three important features that businesses need to prioritize when evaluating a solution in energy monitoring.

3.1. Intuitive interface, easy to use for both technical staff and management

A system for monitoring energy efficiency serve not only technicians, but also to support managers to quickly grasp the situation power consumption, overall or in each production area. So intuitive in the interface design are important factors.

Business should be a priority system are:

- Panel (dashboard) displays the data in real-time chart columns, lines, heat maps... easy to read, easy to understand

- Purchase select the user rights by role to help the department only see the data related

- The ability to customize the metrics displayed in accordance with each industry (for example: kWh/ton of product, kWh/m2 factory...)

Actual value:

- Help managers decisions faster without need to handle data

- Create conditions to all personnel involved in the goal of saving energy

- Increase transparency in the process of operation of internal control

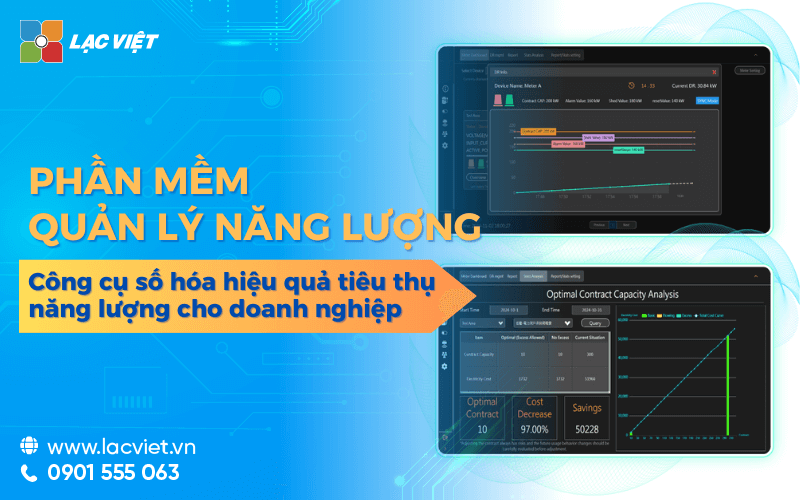

3.2. Data analysis smart – predicted trends in consumption

A software monitoring is the need to do much more than recorded figures. It must have the ability to analyze data to detect abnormal proposed actions aimed at optimizing the operation.

What features should have:

- Comparison of energy consumption between the ca/region/month, detect point wasting

- Performance analysis equipment: equipment which consume more unusual signs wrong operation process

- Tend to predict power consumption based on yield, crop or behavior used previously

- Automatically give recommendations to save energy: for example, proposed to reduce the load on the frame peak hours or shift production to the daylight saving

Business benefits received:

- There are grounds for data to come up with a plan energy saving, reasonable feasible

- Avoid the costs are skyrocketing due to consumption of abnormal or excess committed emissions

- Create a platform to serve the reported emissions Scope 2 standard, GHG Protocol

3.3. The ability to open connection – integrated with the current system of business

Business should not deploy a system of “independent” to separate, because it can cause difficulties when operating the cost of upgrading infrastructure. A monitoring system ideal energy need to be able to open connection (open integration) to sync data with the software system is used.

Specifically, the system should:

- Have API connectivity with ERP software, accounting software, management systems, maintenance, or software environment (EMS)

- Support standard connector, such as Modbus, OPC, MQTT, help associated with measurement equipment available

- Have the ability to export report data in a common format (Excel, PDF, CSV,...) or directly integrated with the platform reporting ESG

Actual value:

- Cost savings initial investment restrictions have to change the infrastructure or other software

- Easily sync data service internal report, emissions reporting or record certificate carbon

- Help construction business management system, the overall energy change for each discrete piece

4. Actual benefits that the monitoring system energy yield for business

4.1. Reduce waste, optimize energy costs up to 15 – 30%

One of the first value most easily recognizable when applying surveillance system, energy is the ability to detect, cut the account waste energy, capital silently exist in operating daily. In fact, many business shows that up to 20 – 30% energy is consumed not effective due to older device, the commissioning process, or there is simply no mechanism for monitoring timely.

For example, A textile factory at the industrial park in Long An, after deploying the system monitoring energy within 6 months, have discovered a number of devices such as the compressor operates 24/7, including overtime production. After adjustment according to the recommendations from the software, they recorded the save more than 20% of the cost of electricity per year, equivalent to nearly 300 million/year.

Enterprise value received:

- Cut energy bills, thereby reducing the cost of production inputs

- Increase the profit margin without increasing revenue

- Help managers easily put KPI energy database clear

4.2. Support certified ISO 50001 certificates, carbon international (GHG PAS 2060...)

Achieving the certificate in energy and carbon is no longer the goal far, which has become the necessary condition to businesses involved in the global supply chain. However, to achieve this certification, a business must prove to be the real effort in controlling, measuring, reducing emissions – something that a monitoring system, energy can be provided in full.

Monitoring systems help businesses:

- Create data transparency, can continuously checked for power consumption

- Construction of the appropriate report according to international standards such as the GHG Protocol (Scope 2), ISO 50001

- Do demonstrate roadmap to reduce emissions, support when filing reach the credits carbon or report ESG

Practical benefits:

- Enhance brand reputation in the eyes of partners, especially the partner requires ESG or Net Zero

- Increase the ability to call capital from the fund green investment, financial institutions, international

- Create advantages in bidding for the huge project, especially exported to European market, Japan

4.3. Improve operating – early detection of risk – enhancing device performance

In addition to elements, energy-saving monitoring system also helps to improve operational quality and safety of the plant. With real-time data with automatic alerts, issues such as equipment operation process, power consumption, unusual or overload is detected early – before they cause serious incidents.

For example, In a mechanical workshop, detection systems, gas compressor has a capacity of 75kW power consumption unusually high at the end of the week – time no production activities. Check out for see valve pressure regulator leak causing the continuous operation is not required. Thanks to timely warning, businesses have to avoid risk of fire and reduce nearly 10 million per month for electricity for own this device.

Benefits:

- Minimize the risk of fire, explosion, damage to equipment due to incorrect operation

- Enhance equipment life, reduce maintenance costs, replacement

- Optimal productivity throughout the system by detecting the point of “congestion of energy” timely adjustment

In summary, monitoring system, energy is not just tool to save power, which is the data platform to help businesses control energy efficient, demonstrated commitment to sustainability and are willing to step onto the playing field of the market with high requirements on ESG. Early deployment, the business will be more active – both in internal management and international integration.

- Industrial what is green? Characteristics of the field applied in Vietnam

- What is green energy? Benefits of different types of green energy for business

- Credits Carbon is what? Market and form purchase and sale of only carbon

- EIA is what? The process of making records assessment report environmental impact

5. How to deploy monitoring system energy efficiency: a Roadmap 5 steps

The application of the monitoring system energy not merely the installation of software and measurement equipment. To bring really effective, businesses need to implement according to a clear roadmap, there is coordination between engineering, management and operation. Here are 5 steps to deploy standard has been applied in many factories, industrial buildings, success:

Step 1: Survey the current state of energy consumption

Before investing in any system, enterprises need to understand the real situation of energy consumption in their units. This survey should be done by the engineering department or internal consultant with experience.

The content needs survey include:

- The total amount of your average consumption by day, week, month

- Allocate consumption by region: the production, office, cold storage, operate the auxiliary...

- The device consumes most current and efficient use

- Whether or not the measurement system was installed?

The value of this step: to Help businesses identify “hot spots of energy consumption,” from that given on the installment plan reasonable, avoid investment wasting.

Step 2: Identify the device should track – Priority area consumption

Not necessarily monitor all devices right from the start. A system for monitoring energy efficiency should start from the area or machinery consume the most energy, where potential savings is the greatest.

Priority should be placed on:

- Air conditioning, industrial air compressor, boiler

- The production line continuous operation

- Water pump system, lighting, storage area, workshop

- Electric cabinet center (MSB) to track the total branching download

Hint: With the business of production, can choose 3-5 point measurement strategy in the first phase, to control the test system efficiency then expand.

Step 3: deploy software and equipment measurement fit

After identifying areas that need monitoring, the next step is to choose software solutions/measurement equipment in accordance with the reality of business.

Keep in mind when choosing:

- Measuring equipment should reach the industry standard, high precision, support remote connection (via Wi-Fi, 4G or local network)

- Software must be friendly interface, easy to use, support to export reports, decentralize role

- Should select the solution is scalable and integrated with the management software out there (such as ERP, ISO, emission system)

Values bring: to Help businesses deploy fast, reasonable cost ready for the expansion later if there is demand.

Step 4: Training team operator – authorization by role

Even good system will also not be effective if users are not guided properly. Therefore, the need training for the related objects, from technicians to management.

Training content should include:

- How to read data from the software, identify abnormal consumption

- How to set warning threshold power

- How to create automated reports service manager or submit audit

- Delivered right to each person according to role: technical, shift manager, technical director...

Benefits: Increases the activity of a team of internal reduction depends on the supply and increase the efficient use of the system.

Step 5: Evaluation – optimization through real data

After the system goes into operation, the business should maintain routine performance evaluation of energy consumption periodically (weekly or monthly), then tune operation.

Need to track:

- Compare actual consumption with the objective set out

- The rate of waste discovered and solutions have made

- Number of equipment operating hours, inefficient operation

- Report carbon emissions (Scope 2) are updated out why

Final value: through collected data, enterprises can develop a roadmap to reduce emissions of science, suitable for filing certified ISO 50001, GHG Protocol or market participants credits carbon future.

Don't just stop at the measurement power consumption monitoring system energy today acts as a “smart assistant” to help businesses identify waste, improve equipment performance, and even more important – creating data transparency for reliable reports emissions, ESG or resumes international certificates.

In the context of the market and the global supply chain is shifting strongly toward the business, blue, transparent, effective, then the investment system power monitoring no longer is choice, which is an essential part in the development strategy long-term. Any business action soon, that business will save more, operate smarter, and grasp the opportunity to lead in the era of sustainable development.