Process import warehouse plays an important role in maintaining the stability and efficiency of production activities and business. A process is not standardized, can lead to the condition of goods loss, overlapping work and reduced work performance. In this article Lac Viet Computing will give businesses the steps standardizing the process to import warehouse efficiency.

1. The process import operations inventory of the business

1.1 process integration repository

Process integration repository is a sequence of operations in business to ensure that the receiving, inspection, storage of goods in an efficient way. To ensure this process goes smoothly and efficiently, businesses should adhere to the steps that have been standardized.

The import process inventory includes the steps of:

- Step 1: construction planning process into the treasury: Business need to plan in detail for the process of warehouses, including the forecasts of the number of goods, time to enter the stock, assigning specific tasks for the relevant parts.

- Step 2: rearrange products, goods in stock: Before shipment, businesses need to conduct re-arrange warehouse to ensure storage space ready for the new shipment. Includes the work check the storage location to arrange the goods back if necessary,...

- Step 3: collate, check products in stock: When goods are moved to parts stock should be conducted for screening the number and quality products with orders or delivery notes. Any errors should also be recorded to handle in a timely manner to ensure the goods enter the warehouse in accordance with requirements.

- Step 4: accounting department, checks and receipt: After the test is finished, the accounting department will proceed to check the information about the goods and receipt. Receipt is an official document recorded the number, the type of goods imported, is the basis to update the inventory management system.

- Step 5: Complete the task according to the regulations: finally, after completing the import warehouse, perform the remaining tasks include updating the information of goods in warehouse management system, arranging the goods to the correct location in the warehouse, establishment report if necessary.

1.2 process of stock

The export process, inventory plays an important role in ensuring the goods are taken out of the inventory accuracy. A process of stock preparation will include the following steps:

- Step 1: suggestions, request stock: production department, business or related parts will give required inventory based on demand. This request should be made in the process of warehouse to send up parts inventory management.

- Step 2: Approval of the stock recommendation warehouse: Stock recommendation warehouse approved by the responsible department. Approving this ensures that the required repositories are reasonable, necessary with the business plan or the production of the business.

- Step 3: Check your product inventory: After polls suggested the repository is approved, warehouse staff will check the status of inventory to ensure it meets requirements are available. If the goods are not enough, there should be measures to regulate or notify the department requires.

- Step 4: invoicing, warehouse and paperwork other: warehouse worker invoicing, warehouse the same procedure for other papers under the provisions of the business. This document is the legal basis for the inventory and accounting of the latter.

- Step 5: For goods in stock according to the regulations: goods that are the last inspection for quality and quantity before the official repository. Businesses can export warehouse according to the principle of FIFO, LIFO, FEFO,...

- Step 6: Update information in the system: finally, after the goods have been export warehouse, warehouse staff will update the information on warehouse management system.

2. Process flowchart warehouse import – export warehouse

2.1 process and warehousing of finished products

Process enter the warehouse of finished products usually take place in the business of producing goods after the friendly will proceed to enter the warehouse.

Process flowchart enter the warehouse of finished products includes the following steps:

- Step 1: Shipping of products on stock – After production, the finished products are shipped from the production department to the repository. In this step need to ensure no loss of energy and does not affect the quality in this process.

- Step 2: counting and sorting at the warehouse – warehouse Staff tally the number of quality inspection under the supervision of the related parts, then sort and preservation of product the correct position.

- Step 3: Set up receipt – accounting department establishment receipt based on data from tally, make sure you have full signature confirmation.

- Step 4: Browse receipt – receipt is manager level approval to become vouchers valid in the report.

- Step 5: Update stock warehouse – the warehouse update the information on card stock, store receipt in related department.

- Step 6: bookkeeping and store vouchers – accounting record information on books and store receipts to inventory management, planning, production, warehouse.

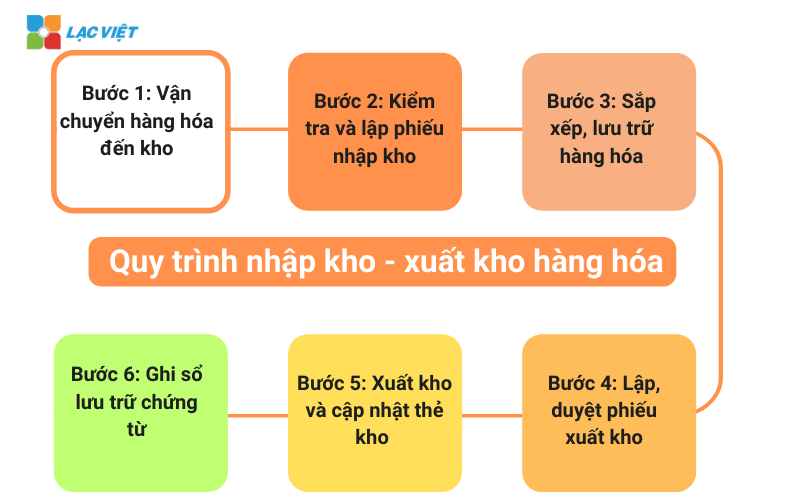

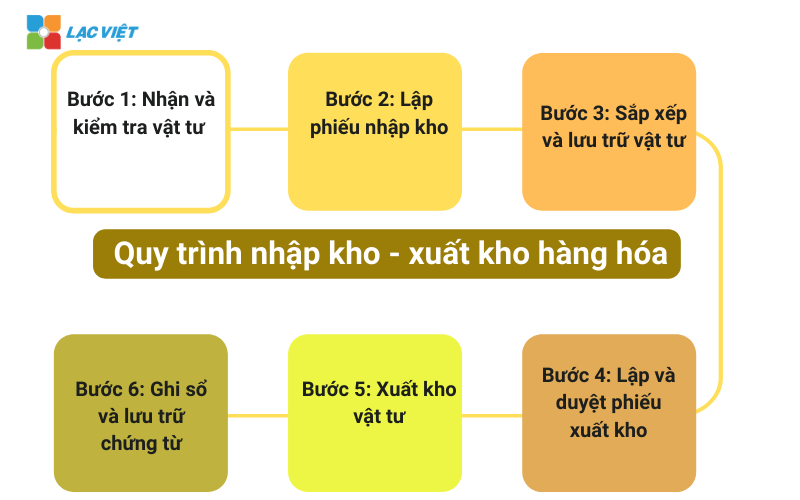

2.2 process warehouse import – export warehouse

Process, warehousing, and inventory of goods plays an important role in ensuring the flow of goods is optimal management. This process typically includes the following steps:

- Step 1: Transportation of goods to the warehouse – When goods are received from suppliers or the production finished, we will be shipping to the warehouse. This process requires extreme caution to avoid loss or damage to the goods.

- Step 2: Check and import warehouse – warehouse worker test goods after received, then they set up receipt, specify the information goods and ensure the votes are full signature from the stakeholders.

- Step 3: Arrange the storage of goods – goods to be sorted into the specified location in stock, adhere to the principle of preservation in order to optimize space management.

- Step 4: Set up, browse warehouse – When requested, cumshot, warehouse, employees in the warehouse based on order or internal needs. Warehouse then be manager level approval before proceeding with shipment.

- Step 5: Export the repository and update card stock – goods is export warehouse according to the process, ensure the right quantity and type. The information warehouse is updated on card stock to track inventory accurately.

- Step 6: Record store vouchers – accounting department recorded transactions and import into the books, vouchers related.

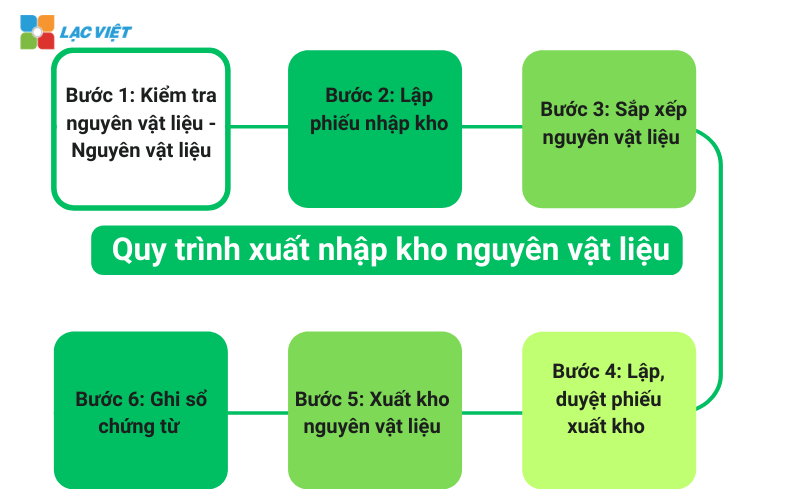

2.3 process, import and storage of raw materials

Process to import the raw materials should be taken closely to ensure the source of raw materials for manufacturing are maintained, stable, meet the requirements of production.

- Step 1: Check raw material – Raw materials are transported from suppliers to the warehouse. Warehouse worker test raw materials to ensure the right orders.

- Step 2: Set up receipt – After checking, warehouse staff establishment receipt, specify information about material, quantity, origin. Receipt should be signed confirmation of the parties involved.

- Step 3: Arrange the raw material – Raw material after entering the inventory is sorted by type, product code, preserved by regulations to maintain quality.

- Step 4: Set up, browse warehouse – When wishing to use the materials, warehouse will be set based on production requirements.

- Step 5: Export the raw material – Raw materials are of stock according to quantity, warehouse staff updates the information on the card stock to ensure data inventory is always accurate.

- Step 6: Record certificate from – finally, the accountant recorded transactions and import into the book store vouchers to assist in the inspection, after this.

2.4 process import warehouse supplies

To ensure the process of using materials takes place throughout the process, import, warehouse supplies need to be standardized. The import process inventory, stock supplies includes the following steps:

- Step 1: Receive and inspect materials – warehouse Staff made check materials to ensure proper with the order request.

- Step 2: Set up receipt – After checking, warehouse staff establishment receipt. Votes warehousing need to have the confirmation of the stakeholders to ensure the accuracy.

- Step 3: sort and store supplies – supplies-after entering the inventory is classified on the storage location fits in the warehouse, ensuring easy access when needed.

- Step 4: Establishment and browse warehouse – When requested use of materials for the activities of production, warehouse will be set up and sent to management for approval.

- Step 5: Export warehouse supplies – supplies is stock in stock has been approved. Warehouse staff updates information of stock on card stock to track the amount of inventory accuracy.

- Step 6: Record and store vouchers – accounting recording of transactions import stock on the books, at the same time storing related documents.

3. Standardizing the process to import inventory control, goods efficiency

During the operation of the warehouse, the standardization process, import – export warehouse role is extremely important, ensure control over the goods rigorously and efficiently

To standardize the business may refer to the following criteria:

- Set the basic steps: clearly Define the steps in the process. Each step should describe in detail to ensure not to miss any stage.

- Standardized forms and documents: Use the standard forms for recording information goods, sample proposals, help to easily track and trace when needed. For example, form, receipt, warehouse should be unity of content and form.

- Specific authorization: At each step of the process, business needs analysis, rights, duties, responsibilities specific to the individual parts, ensuring the work happening throughout, not overlapping, jam stasis.

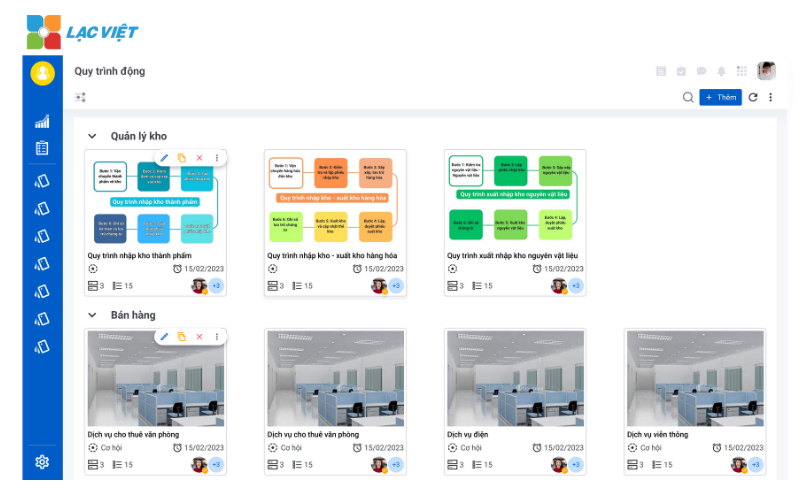

- Digitized processes: application of technology in the process of using software management processes LV-DX Dynamic Workflow to digitize the entire process from data entry to store information.

Software, LV-DX Dynamic Workflow is a tool to manage the process of optimizing and standardizing the process to import the repository, helps reduce manual steps, enhance transparency and efficiency in the control of goods.

- Set the standard process: build process import stock details including steps such as building plan, collate, check, set, stock,...

- Automate work flow and assign work: Each step is digitized automatically and assigned to each individual specific parts. All operations from input to store information both on platform number, create data warehouse intuitive, easy to access.

- Close authorization: Each individual has powers clearly in step by step process. Every action in the process is recorded and stored.

- System reminder: set a deadline for each step, ensuring completion on time.

- Integrated tools approved online inquiries: Management can browse request and handle related issues from anywhere, at any time.

- Control and evaluate the effectiveness deployment: the reporting tool, The visual statistics system with intuitive charts, offers an overview process, inventory management for business.

Standardized process import warehouse not only to help businesses control of goods closely, but also optimized the operational efficiency, reduce errors and risks. The support from the management tool that will improve transparency, automate work-flow and make sure that every works import warehouse are properly carry out the process. This is a necessary step for the business in the context switch number, to help increase competitiveness and increase performance.

CONTACT INFORMATION:

- Lac Viet Computing Corporation

- Hotline: 0901 555 063 | (+84.28) 3842 3333

- Email: info@lacviet.vn – Website: https://lacviet.vn

- Headquarters: 23 Nguyen Thi Huynh, P. 8, Q. Phu Nhuan, Ho Chi Minh city