ERP printing industry is planning system enterprise resource be customized to comprehensive management from the time of order, design, production, material management, warehousing to financing and delivery. The system helps to optimize costs, enhance operational efficiency, quality control, printing products, at the same time solve the problem peculiarities of business printed as management material, machinery and norms as well as the progress of the production complex.

However, many businesses print, especially the unit has the production process complexity or scale, often have difficulty in the management sync the stage, track inventory, machinery and exact cost. The operated using Excel or other software, discrete, easily lead to the wrong number, delay progress, as well as profit does not reflect the true reality.

Therefore, ERP implementation in printing properly is the necessary step to standardize processes, automate management and provide accurate data to enhance the competitiveness of sustainable business. The same Lac Viet detailed analysis of the ERP industry in roles, functions, objects should apply and criteria for selecting appropriate solutions.

1. The common problems of printing business today

- Difficult to control the cost of raw materials – paper, ink & loss of production: Paper and inks accounts for a large proportion in the cost of production regular price fluctuations. When tool management concentration, business difficult to control consumption, inventory and shrinkage, leading to price the exact quote less competitive.

- Production planning craft, easy-to-late delivery schedule: scheduling by Excel or paper craft made business in the overall capacity, machinery, labour and raw materials. When the order changes, the production schedule is not updated timely, leading to poor coordination effective, easy to delay progress, influence, credibility, increasing operating costs.

- Giá thành không chính xác, khó báo giá cạnh tranh: Giá thành sản phẩm in ấn phụ thuộc vào nhiều yếu tố như giấy, mực, nhân công, máy móc và chi phí gián tiếp. Khi dữ liệu phân tán việc cập nhật thủ công, doanh nghiệp khó xác định chính xác chi phí theo từng đơn hàng, dẫn đến báo giá kém cạnh tranh. Hệ quả là biên lợi nhuận bị thu hẹp hoặc doanh nghiệp đánh mất cơ hội kinh doanh, ảnh hưởng trực tiếp đến dòng tiền và khả năng cạnh tranh.

- Discrete data between departments: business – manufacturing – accounting: When data is not continuous, each department only holds a part of information, make business quotes, teen, teen, tight, reality, production updates deferred accounting loss of many synthesis time.

The discrete this reduces the effective coordination, slow response to customer demand and limited ability to analyze data in service decision management.

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Giải pháp Lạc Việt ERP cho khách sạn: 6 tính năng nâng cao hiệu quả vận hành

- ERP ngành nội thất: Chức năng & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP

- ERP ngành thiết bị điện là gì? Giải pháp nào giúp DN quản trị toàn diện? – Lạc Việt ERP

2. ERP printing what is?

ERP industry in india is a system management software comprehensive is designed in particular to meet the operational processes of the enterprise in printing industry. After receiving orders, production planning, tracking supplies, to expense management and reporting results of operations, all of which are concentrated in a single platform.

Other than the software manage discrete (for example Excel for quote, a software for production and the other part for accounting), ERP printing, connect the data and processes together to help the parts no longer work independently without real coordination. This creates a “single data source” to all decisions are based on accurate information, updated in real time.

In the printing industry, ERP is deep customization to handle the particularities like:

- Order according to customer requirements: Each job in have different requirements on the gauge, type of paper, colors, machining... not like the mass production standard.

- Sequence of stages of production varied: In – rolled – closing – packing, every step has own number.

- Adjust the level of supplies (paper, ink) according to the actual production to calculate the true cost.

Thus, ERP in the printing industry, not only is management software that is a decision support system to help business measure accurately the performance of each job in.

3. The professional printing industry other nothing compared to conventional production?

An ERP system standard production management, accounting, purchase, warehouse, hr... but usually not thoroughly handle the complex requirements special printing industry. Meanwhile, ERP industry, printing is customized for the following:

3.1. Manage your orders according to job printing & design files

In printing, every order is often accompanied by a design file, the requirements for color, size separately. ERP industry in manage each job in detail, instead of just under the product code generic, help reduce errors when the transfer from trading to manufacturing.

If there is no centralized system, the information about the job in (for example, requirements for color, size, precision) can be missed when moving through the handle, leading to products in the wrong request and expense of editing.

3.2. Scheduling production by machine, print & capacity

Other production simply quantity, printing request scheduling in a way, fit with the paper size, capacity, working time each ca help production efficiency as well as optimal machinery.

For example: A job in large can only be run on 1-2 certain machine. ERP printing help allocate automatic balance time to avoid duplicate calendar and congestion production.

3.3. Track consumable materials according to the actual

In the production of printing, paper and ink is the material making up the bulk of the costs. Other than ERP general, the ERP system printing allows the recording level attrition fact on each job printed from it compared to the standard level given warning when exceeding the permitted threshold.

A job in the big can arise the paper, amateur, ink wastage... If it is not followed exactly, business vulnerable to losses because not enough production costs.

3.4. Calculate the price of detail in each print

Instead of calculating the price of generic, by product, ERP printing set the cost of raw materials, labor, machinery, shrinkage, machining women... to calculate the price according to the menu. This helps businesses:

- Quotes competitive, but still assure a profit.

- Price comparison of reality with the estimates to plan more accurate in the future.

ERP system in printing is not just accounting software/ inventory management/ production the same as the conventional system. It is a management platform focused, in-depth analysis of the industry, which helps the business in operational efficiency, cost control, speed up the production process to improve the accuracy in the price & delivery.

4. The subsystem core ERP printing industry need to implement?

ERP system in the industry in not only is a set of software tools, discrete, which is a system that integrates data and processes, help business link the step to operate from the moment of receipt to delivery of the product.

4.1. Manage quotes & orders in

In the industry of printing, every order often have particular about material, size, color printing, as well as requires machining. Ago ERPthe quotes is usually done by Excel or personal experience, easily lead to errors and virtual profit.

ERP helps:

- Auto connector quotes with real data about supplies & machine capacity: When entering a request in, the system will check the inventory paper, ink, labor, and machinery available to give more accurate quotes.

- Reduce the deviations between the price & cost fact: this helps the business avoid alert the prices are too low lead to holes or too high, causing loss of customers.

Businesses can increase the accuracy in the price. At the same time, reducing the risk assessment cost wrong, thereby improving profitability on every order. Data integration helps leaders timely decisions based on real production, not feelings.

4.2. Production management in according to each stage

One of the biggest challenges of the business is to ensure each and every stage from printing, lamination, closing to packing out the right plan. If management paper sheets or Excel, data often slow, error and lack of continuity.

ERP printing support:

- Planning according to the machine, according to work shift, specify the order of the job in competency-based practice.

- Track progress in real time: each stage is recorded automatically when finished instead of depending updates manually.

- Time recording run/stop the machine/the actual output.

Business capture the level of finishing work immediately, timely detection of the point of obstruction and adjust production plans, reduce the time delay. This step is essential to achieve optimal productivity, as well as shorten the production cycle than operating traditional.

4.3. Material management – inventory industry in

Inventory management problem is critical to the business printing for paper, ink, and materials are accounted for a large share of the costs. If inventory is tracked deviations business easy to fall into the condition:

- Buy supplies excessive lead to inventory died.

- Lack of supplies, while production is ongoing, disruptive progress.

ERP helps:

- Track inventory by paper quantitative, lot – not just according to the number of the total.

- Monitoring consumption inks, materials according to each order.

- Warning order automatically when inventory hits a minimum.

Businesses can optimize cash flow by reducing excess inventory, while ensuring supplies are always ready when needed, avoid disruptions to production as well as costs incurred are not necessary.

4.4. Manage high quality printing

In the ERP industry, printing, quality is the determining factor satisfaction of customers along the repeat orders after this. When any data quality checks are stored on the tools of discrete tracking defects or cause errors products very difficult.

ERP support:

- Set up process, check the quality standard at every stage of production instead of the random test.

- Recorded & track test results to make the foundation for continuous improvement.

Minimize defective products, increase the rate of delivery of the right quality, from which improve customer experience and reduce the cost of re-processing.

4.5. Management printing machine

Machinery in the property strategy as well as cost of investment. If not managed effectively, the machine stops suddenly will make the production line slows down.

ERP helps:

- Schedule maintenance periodically based on the time the actual operating technical criteria.

- Track performance over time to forecast, adjust the production plan.

To reduce downtime is not expected, prolonged equipment life and increasing production capacity overall.

4.6. Accounting – finance – management reports focus

One of the special values of the solutions ERP printing industry is systematically associated production data to accounting as well as financial reports, remove stage input crafts, take time and errors.

ERP provides:

- Automatic update accounting data from manufacturing: raw material costs, labor, the general expenses are recorded when incurred.

- Report profitability by customer order, customer, product and in – help leadership compare the results between groups of product or customer flow.

- Management reports quickly & regulatory compliance, accounting, tax.

Businesses not only have financial data more accurately, but also have the ability to analyze profit in detail, from which the decision to increase/decrease prices, cut expenses or invest in products and services strategy.

5. Business in how we deploy ERP printing industry?

Investment in the ERP system is a strategic decision, which helps business to operate more efficiently on data platform focus. In it, there are two groups of business printing particularly suitable to implement ERP.

5.1. Business commercial printing & packaging printing

The peculiarities of this group is the order diversity, large number of small single-and ask for fast delivery. This is also the group to risk on the cost of raw materials, inventory the same production schedule if you are still operated manually or separate data each department.

With an ERP system printing industry:

- Control the cost of paper, ink and consumable materials according to the order is done right in the process, thanks to which the business can cost calculation more accurate.

- To increase transparency to the progress of production, from receipt until delivery. Information is updated in real time between sales, production and inventory, help the sales department feedback correct with the client to improve reliability.

- Inventory management flexibility, reduce residual ink or deficiency caused sudden fracture orders. ERP system enables to forecast raw materials according to the production plan, from which the optimal rotation of working capital.

These values are especially suitable with businesses in commercial and packaging printing, where variable cost flexible operation decision directly to competitiveness.

5.2 Business in scale, medium & large

For enterprises with multiple printers, multiple stages, as well as a more sophisticated process management system, a single, easily lead to data scatter, poor continuity and difficult to standardize processes. This is a typical situation that ERP advantage:

- Standardized operation process, from business to manufacturing and accounting, creating a source of data consistency, ensuring decisions are made based on accurate information in a timely manner.

- Manage multi-stage, complex manufacturing, from planning, printers, allocated resources to track progress finished each batch in. ERP helps reduce overcrowding in a number of stages of “dead air” prolonged due to schedule conflicts.

- Report & cost effective investment easier, help leadership performance tracking each production sector, profitability by product or line. At the same time, the system supports monitoring costs as well as profits, according to orders, base building strategy the competitive price.

With business in scale, medium & large ERP not only the management tools, but also is the foundation to scale, normalize data, create resilience sustainable competitive.

6. Signs that it's time to need ERP

Here are the signs practical, easy identification in the operations element for file management system, current no longer fit the business has touched the threshold need to switch to the ERP software industry in india:

- Profit does not increase commensurate with turnover: Usually operating costs, lack of transparency, inventory difficult to control, waste materials or quotes deviations compared with the actual cost. ERP data link accounting and production, measurement costs according to each order, as well as calculate profits accurately.

- System manager current was too download or fragmentation: Data updates slow, difficult synthesis report. ERP integrates information from the department, to help lead capture timely and comprehensive business activity.

- Operating procedures depends heavily on personal experience: When personnel changes or the volume of work big business risk. ERP standardized processes and sync data, limiting the decision according to the sense.

- Inventory difficult to control & cash flow slows it big: Paper, ink, and materials accounted for most of the cost input. When not managed by the framework, quantitative, lot, business, easy, shortages or inventory to die. ERP forecast inventory with automatic alerts, reducing costs of storage and freeing up cash flow.

Implementing ERP in the printing industry, not only is the application of technology but also the step switch management help to raise the possibility of operating, sustainable growth. Investment decisions should be based on the signs fact, especially when management tools, current no longer meet the speed as well as accuracy in the business environment competitive.

7. Selection criteria ERP printing suitable

Selection of ERP not only is the decision technology, but also strategic, directly affect the operational efficiency, cost control aims at sustainable growth. Three criteria below to help businesses in reviews as well as select ERP solution fit.

- Suitable peculiarities printing: printing process operate multiple stages from receiving file, browse, printing, lamination, carried to the packing. ERP printing industry helps to track progress, as well as cost details each stage, calculate the price of exactly the raw materials, machinery, labor, and the production time ensuring profitability reflects the fact.

- Flexible – easy expansion – easy to use: ERP efficiency must be consistent with the management capability of the same development plan, intuitive interface, ease of training for employees, does not require a team of IT professionals. Flexible system scalability when increasing order, the more branches or deploy new services without interrupting operation.

- Implementation partner knowledgeable industry: the Success of ERP project depends on the partner understand the peculiarities operate in, set the module fits, deploy transparency to reduce production interruptions and ensure transfer of accurate data. At the same time, long term support, upgrades, as well as optimize the system according to the needs to the business development.

To find out ERP in the printing industry, the business should choose the solution that meets three criteria: fit the peculiarities industry, flexible, easy-to-use as well as for the deployment knowledgeable. Only when that new ERP optimal operation, control costs and enhance competitiveness and sustainable.

- Solution Vietnam ERP for textile industry standards & compliance legal

- System LV ERP for chemical industry: solutions & selection criteria ERP suitable for business

- Lac Viet ERP in construction industry management intensive treatment for DN in Vietnam

- ERP ngành bán lẻ là gì? Giải pháp Lạc Việt ERP tối ưu vận hành & tăng trưởng bền vững

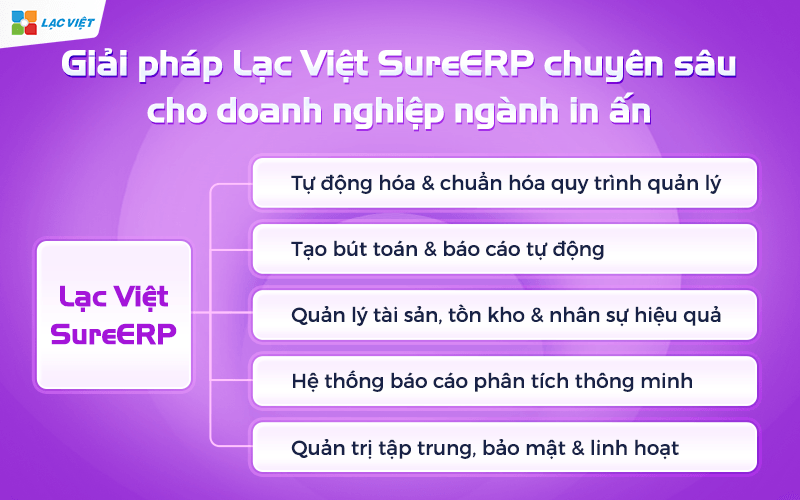

8. Giải pháp Lạc Việt SureERP chuyên sâu cho doanh nghiệp ngành in ấn

To optimize the whole process of business management, business can apply software lacviet SureERP, a solutions ERP printing comprehensive automation and transparency all activities:

- Automation & standardized management process: SureERP supply analysis, sales management, purchasing, production, inventory, finance, hr... track the entire business process, automatic recognition, service, reduce errors, and ensure compliance with accounting regulations.

- Create accounting & reporting-automatic: SureERP recorded automatically the pen cost, revenue, public debt and taxes. At the same time offers more than 300 financial reporting, governance and tax. Easily track overall as well as detailed activities and evaluate the effectiveness department, cash flow, to the correct decision.

- Asset management, inventory, hr & effective: SureERP track fixed assets, supporting depreciation, maintenance, and warranty. Inventory management, multi-dimensional, control, limit, age, top, cumshot, inventory FIFO/LIFO to optimize capital. The hr and payroll, records management, attendance, performance evaluations, as well as planning, training, ensure operational efficiency resources.

- The system analysis report smart: SureERP integrated BI tool analyzes multi-dimensional business data, market reviews, sales effectiveness, personnel as well as costs, at the same time information visualization to support decision fast and accurate.

- Centralized administration, security & flexibility: SureERP allows decentralization, traceability data, customized system multi-branch, multi-language, multi-currency, at the same time flexible integration with other systems, ensuring comprehensive security.

The deployment of Lac Viet SureERP not only help businesses improve efficiency overall administration, save time, reduce costs and risks. But also support strategic decisions based on data, transparency, accurate. To experience directly and find out details, visit: https://erp.lacviet.vn/.

ERP printing industry to help businesses enhance operational efficiency, cost control, optimal profit. System data link between the parts, standardize processes, reduce errors as well as increase the speed of decision making. ERP also supports production management, materials, warehousing and financial performance, while improving customer experience with competitiveness. This is an important foundation for enterprise in sustainable development and flexible with changes of the market.

- Lạc Việt ERP ngành thiết bị y tế quản trị vận hành đáp ứng chuẩn chất lượng & tuân thủ pháp lý

- Lạc Việt ERP cho ngành công nghiệp phụ trợ tối ưu quản trị sản xuất – chuỗi cung ứng cho DN Việt

- Lạc Việt ERP ngành cơ khí: Phân hệ & Giải pháp ERP phù hợp doanh nghiệp Việt

- ERP ngành thủy sản: Giải pháp & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP