ERP system industry electrical equipment is a software platform that helps business of production, distribution and construction equipment electrical centralized administration of the entire operation from purchase, inventory, production, sales to financial accounting. In the context of market power equipment competition, high profit margins squeezed, supply chain fluctuations, ERP not only help control costs, but also enhance the ability to make decisions, optimize cash flow, scaling sustainable.

However, many businesses electrical equipment are still experiencing difficulties in managing complex production, inventory control, product price calculator or track your supply chain, the long-term. These gaps not only reduce the operating efficiency but also potential financial risks, affect decision-making abilities, as well as competitiveness in the market.

To understand these challenges and apply the methods of modern management is the important step to business control costs, optimize cash flow, as well as sustainable development. The same Lac Viet find out detailed management system industry electrical equipment, the core benefits and how to implement effective for the business.

1. Why business industry electrical equipment needs ERP system specialized?

1.1. Peculiarities operate complex of industry, electrical equipment

Business industry electrical equipment often see the particular operate the following:

- The category products large lot of code, using the same specifications made management, inventory planning, supply complex.

- Manage inventory by lot number, serial number and warranty expiration, especially with components, as well as the need for traceability.

- Combine multiple business models at the same time: production – commercial – retail – distribution, creating data stream multi-dimensional need to sync.

- Depending on the plan supplies the progress of orders, lack of connection between the parts can lead to slow progress or excess inventory.

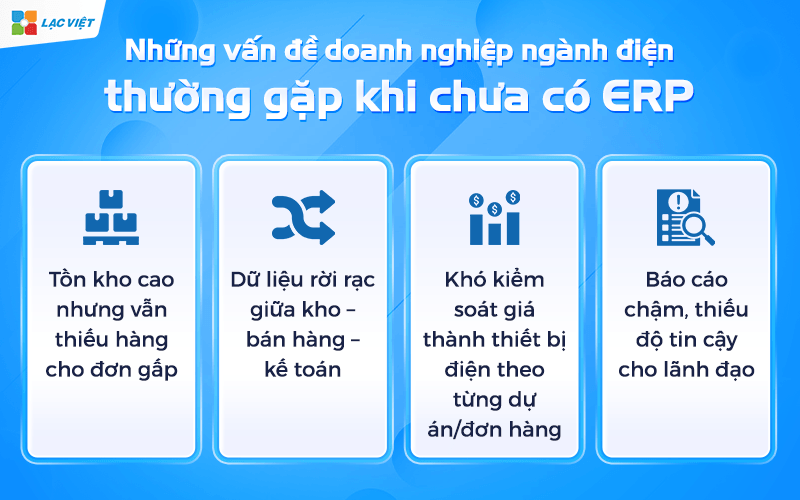

1.2. The problems enterprises often encounter when there is no ERP

While not apply ERP industry, electrical equipment, many enterprises electrical equipment often meet the practical difficulties:

- High inventory but still cute top for simple folding: Do not have data inventory, real-time business easy to order excess or deficiency, which leads to cost working capital lost sales opportunities.

- Discrete data between the inventory – sales – accounting: The parts working independently, the data is not synchronized, causing difficulty in control, as well as analyze business performance.

- Difficult to control the price of electric equipment according to each project/order: When information about raw materials, labor, and production costs are not synthetic focus, business difficult to determine the profit margin of each project.

- Reports slow, lack of trust for leadership: process the resulting report is not timely, accurate, why leaders lose the ability to make decisions quickly and effectively in situations of market volatility.

These problems not only affect the operational efficiency, but also a direct impact on cash flow, profitability and competitiveness of the enterprise on the market.

ERP helps business industry electrical equipment sync data from inventory, sales, purchase, production to finance, to provide instant information for leadership decisions. Integrated systems analysis, inventory, production, price, buy – sales, optimize costs, reduce excess inventory, enhance capital efficiency transparent operating procedures, from which improve productivity, reduce errors and improve the quality of customer service.

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- Giải pháp Lạc Việt ERP cho khách sạn: 6 tính năng nâng cao hiệu quả vận hành

- ERP ngành in ấn là gì? Chuẩn hóa quy trình & tiêu chí lựa chọn ERP – Lạc Việt ERP

- ERP ngành nội thất: Chức năng & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP

2. ERP system industry equipment what is power? What other ERP usual?

2.1. ERP industry, electrical equipment

ERP system equipment power system is resource planning business be customized for particular production to distribution electrical equipment. The system allows centralized management of services, from warehouse, components, production planning, quality control, to finance, hr and supply chain on a unified platform.

Thanks to data connected throughout, businesses can automate the optimum operating resources, reduce waste, as well as enhance competitiveness in the long term.

2.2. Compare ERP industry electrical equipment & ERP common

| Criteria | ERP common | ERP industry, electrical equipment |

| Scope management | The basic functions: purchasing, inventory, sales, accounting, hr | Management peculiarities products, multi-code, multi-specifications, voltage, capacity; manage product variations. |

| Production process | Produced according to the standard lot less variation | Production according to orders, necklaces or project; control progress, quality, cost exactly. |

| Inventory management | According to the items, the number of | Inventory multi-dimensional code, plots, technical characteristics, expiry date, location repository; demand forecast according to technical characteristics and seasonality. |

| Reporting & analysis | Basic report: revenue, costs, profits | Report multi-dimensional, details of inventory, capital turnover, performance, production and sales by product group technique. |

| Customization & integration | The ability to customize restrictions | Flexible integration with software engineering, measurement, ERP master or CRM, responsive operation process peculiarities. |

3. The analysis core in the ERP industry, electrical equipment

3.1. Management, purchasing & suppliers

Planning to buy crafts or according to experience easily lead to lack of raw materials, inventory, excessive, or the cost of buying high do not control the policies and supplier performance.

ERP system with Management purchasing & supplier:

- Planning to buy supplies based on inventory safety: systems analysis current inventory, forecasting demand according to the production plan/orders, automatically create purchase requests before out of stock – reduce risk shortage of raw materials.

- Control purchase price & tracking delivery schedule: every proposal reviews, contract, purchase, are digitized. ERP kept the price history according to the supplier, to help compare and negotiate better. Warning fluctuations, delivery schedule help the timely coordination of resources.

- Reduce the risks lack of supplies for production/construction: data of real-time helps avoid the “off the supply chain small” cause slow progress of the project.

ERP helps to minimize urgent orders, cut the inventory does not need to raise bargaining power with suppliers, from which improves cash flow and operational efficiency.

3.2. Inventory management equipment electric multi-dimensional

Peculiarities products industry electrical equipment is multi-code format, many, lot, serial number, requirements traceability. Manage your often causes false data, inventory, difficult to follow old inventory and slow-moving.

ERP system industry equipment electric assist:

- Management according to (code, batch, series, stock, location,..): inventory is recorded according to each characteristic. Each transaction import – export – adjustments are recorded in detail and fast access.

- Track the age of inventory, warning the slow rotation: real-time data to help determine which products long days don't use/ sell, from there make a decision rotation/discount/goal get fit.

- Optimal working capital: inventory accounting capital is “the maths of life” with business electrical equipment. ERP keep the level of safety inventory is low to medium meet the producers, just do not close the capital surplus.

Accurate data each warehouse location, lot, and every help administrators understand the liquidity of inventory, reduced costs of storage, as well as risks behind schedule due to lack of supplies.

3.3. Manager manufacturing & assembly (if available)

Component manufacturing, electric equipment, production management is the heart of operational efficiency. Deviations between actual plan easily lead to delay delivery schedule, material wastage and cost control.

The ERP for manufacturing provides:

- Production planning according to the order: ERP determine the production schedule optimization based on orders, machine capacity and resources.

- Calculate the demand for raw materials under the BOMBS: the system automatically calculate the required materials for each product according to the level, reducing the risk of wrong calculation leads to excess raw materials.

- Performance evaluation machinery: real-time data to help measure performance, downtime, thereby optimizing maintenance schedules/maintenance.

Business actively adjust the production plan according to the market demand, reduce machine downtime and increase equipment productivity.

3.4. Sales management & distribution

Sales process industry-electrical equipment often associated with the price policy according to agents, contractors and payment cycle long. Errors in sequence as well as orders easily lead to deviations revenue uncontrolled public debt.

ERP helps:

- Manage quotes, orders, policies, price – discount: system to create and store a history quotes, automatically apply the policy to the correct price for each partner.

- Track debt agents, contractors: data public debt are updated in real-time alerts when a payment is due to business proactive recovery.

- Analysis of sales by region, product: reporting, analysis, sales, identify market trends, focusing on products that have high profitability.

ERP industry, electrical equipment help to increase the ability to meet customer requirements quickly, reduce errors in orders, and improving the efficiency of capital recovery.

3.5. Accounting – finance & costing

Calculate the price of deviations can cause business reporting false profits, which affects product pricing and pricing strategy.

ERP responsible:

- Calculate the price of electric equipment according to each application, each project: automatic synthetic material costs, labor, and production costs indirectly to calculate the price accurately.

- Manage cash flow, profits and losses according to the channel: cash flow, profit and loss is shown by sales channel, help leadership priority channel highly lucrative.

- Appropriate accounting standards in Vietnam (VAS): financial data, comply with regulations, meet the audit requirement as well as official reports.

The consistent financial data, business, business help leaders track business performance, strategic decisions promptly, reducing the risk of errors due to input manually.

4. Practical benefits when implementing ERP industry, electrical equipment

ERP implementation specialized help optimized business operated from inventory, production, sales, to finance, to bring more practical benefits:

- Increase operational efficiency & normalization process: eliminate manipulation craft, standardized process from purchase, inventory, production to sales and accounting, and reduce errors in order to improve high speed handling.

- Inventory control & materials: inventory Management, commodity code, batch, series, warehouse and location, optimal rotation of inventory, freeing up working capital as well as ensure stable supply.

- Improve the quality of data & decisions: Integration of data between departments, provide reports, KPI. Performance analysis, real-time decision support fast and accurate.

- Improve cost control & profit margins: Reduce operating costs, optimize purchasing and storage, enhanced accuracy, calculate the price of the project, as well as orders, improve financial performance.

- Increased ability to meet customer & competitive market: Manage quotes, orders, public debt aimed at planning, timely delivery, improve customer service as well as competitive advantage.

- Governance support long-term strategy: effective analysis by sales channel, product and project support, planning, expansion, business development, investment in order to maintain sustainable growth.

5. Business industry electrical equipment should choose ERP system like?

To deploy the ERP industry, electric equipment efficiency, business industry, electrical equipment need to choose the system in accordance with the characteristics operate, scalable bring the real value for the business. Here are the important criteria to consider:

5.1. Match the business peculiarities industry, electrical equipment

Businesses need an ERP has the ability to meet the operating requirements of separate branches:

- Inventory management, multi-dimensional: ERP Systems need detailed tracking in the product code, batch number, serial number and location warehouse, help to control the exact amount of inventory, reduce the risk of loss as well as misappropriation of funds.

- Support planning materials (MRP): ERP must provide a forecasting tool, as well as planning the demand for raw materials, ensuring no deficiency in the production or construction, from which maintain project progress as well as the optimal cost.

- Detailed reports & timeliness: the System must provide sales reports, public debt, the cost of each project or orders, help leaders to grasp the situation commissioning instant the correct decision.

The selection of ERP in accordance with professional characteristics help the business to control inventory, cost, and schedule in an efficient way, while minimizing the risks in operation, increase productivity as well as quality service.

5.2. The ability to customize flexible, according to operating procedures

An ERP system ideally should not force businesses to completely change the business model, which need support customized to fit the actual process.

- Adjust module according to business: allow custom module in accordance with manufacturing, warehousing, construction, and sales.

- Automation & intelligent alerts: Support inventory alert, progress and cost overruns estimates reduce errors as well as save time.

- Custom report: allow To set the reports and dashboard according to own needs, help leadership decisions in a timely manner.

- Deploy less disturbance: ERP for easy integration into existing processes to help staff quickly receive and use.

Possibility of customization flexibility to help ERP adapt to the actual operation extended by the development needs of the business.

5.3. User experience & support after deployment

Effective ERP industry, electrical equipment, not only based on features, that also depends on the level of personnel capture using the system:

- User-friendly interface, intuitive: menus, reports, and dashboard need easy to understand, easy to manipulate, reduce training time. Increased application possibilities right from the early stages.

- Personnel training, comprehensive: Provides program instructions in detail before implementing continuous support after the system went into operation and help staff become familiar with the process and maximise the features of ERP.

- Technical support & consulting solutions: ERP vendors need to be ready to assist when problems arise, technical advice on how to optimize operational processes based on real data.

- Extraction of maximum value: a good user experience combined with professional support helps to reduce errors, save operating time improve the overall performance of the business.

An ERP with experience user friendly and support after deployment, comprehensive, will not only ensure the process operate smoothly but also to help businesses quickly obtained value from investment software.

5.4. The ability to expand as growth strategy

ERP should be the foundation to operate the long term, not only solve current needs:

- Expansion module according to the needs: the System allows additional modules, new business development, manufacturing, market expansion or development to add the new business.

- Integration with backend solutions: ERP should easily integrate with tools such as CRM, project management, management, logistics, or business analytics (BI) to optimize operational processes overall.

- Upgrade technology easy: the Ability to upgrade without interrupting the current operation helps business updates new technology, improved performance and security.

Scalable this ensures ERP is not just short-term solutions that become the foundation of strategic business support, optimized operation, increase efficiency, sustainable development in the long term.

5.5. Total cost of ownership & ROI expected clear

Choose from ERP to consider comprehensive in terms of cost, value of investment:

- The total cost of ownership (TCO): includes the cost of copyright, deploy, maintain, upgrade and technical support. Full calculation helps business is not unexpected with the costs incurred.

- ROI assessment is expected to: Identify the benefits from ERP through indicators such as reduced inventory, improve productivity, reduce operating costs, improve profit margins, as well as effective project management.

- Comparison of cost – benefit analysis of investment costs compared with values yielded to choose ERP optimization, to ensure effective financial and operating.

Reviews thorough cost, ROI, help businesses choose the ERP industry, electrical equipment fit, ensure the system bring real value and support sustainable growth as well as enhance effective business management.

- Solution Vietnam ERP for textile industry standards & compliance legal

- System LV ERP for chemical industry: solutions & selection criteria ERP suitable for business

- Lac Viet ERP in construction industry management intensive treatment for DN in Vietnam

- ERP ngành bán lẻ là gì? Giải pháp Lạc Việt ERP tối ưu vận hành & tăng trưởng bền vững

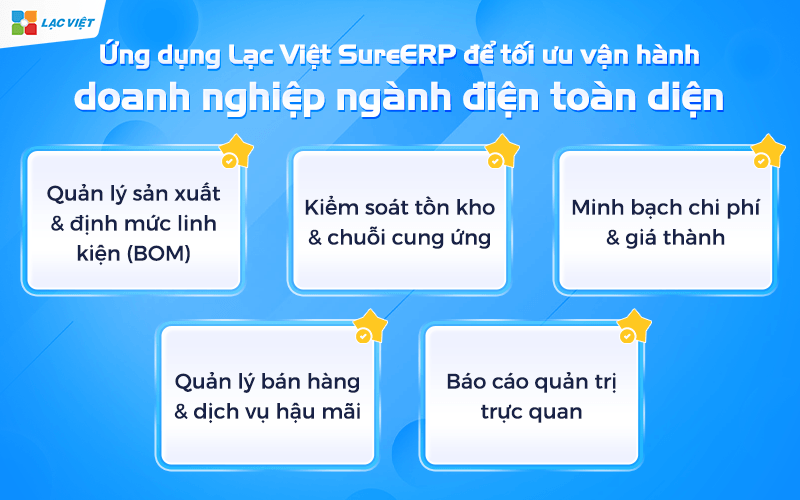

6. App Vietnam SureERP to optimally operate the business industry comprehensive power

For business production – distribution equipment electricity, the big problem is not just manage each service that is the lack of platform data connection between production, inventory, finance and sales. Lac Viet SureERP help standardize processes, transparent data improve operational efficiency overall.

- Production management & norm components (BOM): set the BOMB, multi-level auto-update when the design changes. Reduce errors and raw materials and waste, ensuring the production plan.

- Inventory control & supply chain: track raw materials, semi-finished products as well as finished products in warehouse, location, shipments, helping to actively purchase and optimal working capital.

- Transparent cost & price: the Total expenses from the department to calculate the price of products and orders, control profit to accurately price.

- Management, sales & aftersales service: sync sales, debts, warranty, and technical services, advanced quality of service to retain customers.

- Report intuitive administration: Synthetic data production, inventory, finance, as well as business, real-time support leadership decision fast and accurate.

App Vietnam SureERP help business electrical equipment optimization, service, and build management platform sync, transparent. Easy-to-open wide – the ideal solution for businesses that want to implement ERP industry electrical equipment and sustainable development. Detailed information about the solution at: https://erp.lacviet.vn/

The deployment of ERP industry, electrical equipment, not only help the business closely controlled manufacturing, inventory, costs and supply chain, but also create management platform sync, transparency as well as ready to expand as business grows. ERP system support quick decisions based on real-time data, optimize resources, reduce operational risk. Thus, enterprises can improve operational efficiency, improve margins, increase competitive capacity in the market.

- Lạc Việt ERP ngành thiết bị y tế quản trị vận hành đáp ứng chuẩn chất lượng & tuân thủ pháp lý

- Lạc Việt ERP cho ngành công nghiệp phụ trợ tối ưu quản trị sản xuất – chuỗi cung ứng cho DN Việt

- Lạc Việt ERP ngành cơ khí: Phân hệ & Giải pháp ERP phù hợp doanh nghiệp Việt

- ERP ngành thủy sản: Giải pháp & tiêu chí lựa chọn ERP phù hợp – Lạc Việt ERP