Businesses have to manage dozens of stage production, hundreds of devices and thousands of employees at the same time? Or business are still in control quality craft products, each stage, each product? Software production management comprehensive operation seamless, is the solution to support business planning, progress tracking, production, check product quality,...

In this article Lac Viet will exploit these aspects revolve around công cụ quản lý quy trình sản xuất, từ đó làm cơ sở để doanh nghiệp tìm là phương án phù hợp nhất.

1. Problem of managing the production process, causing concern for enterprises

Nhiều doanh nghiệp sản xuất phải đối mặt với các chi phí ẩn khi, bao gồm thời gian chết không mong muốn và sự lãng phí nguyên liệu khi quy trình làm việc đột ngột dừng lại. Theo ước của Siements, việc ngừng hoạt động không dự kiến có thể tiêu tốn trung bình 532.000 USD mỗi giờ, dẫn đến tổn thất lên đến 172 triệu USD mỗi năm đối với các nhà máy sản xuất lớn.

Meanwhile, the study of APQC turns out that the use of management methods, the production process can increase manufacturing costs up due to the lack of efficiency in the management of labor and raw materials.

Nhìn chung, hầu hết các doanh nghiệp sản xuất Việt Nam và Quốc tế đều đang phải đối mặt với thách thức sau, đặc biệt vấn đề càng trở nên cấp thiết khi thiếu phần mềm quản lý sản xuất:

- 't capture the defective product at every stage, why the error causing the investigation of the source of the problem lasts, stagnant production progress and slow to respond to customers.

- Departments discrete, lack of coordination, information is not synchronized, consistent, to cause delay, interruption in the production process of the business.

- Control inventory no flaws, leading to a shortage of goods, or inventory, too much.

- Difficulty in controlling the quality of products, leading to defective products rate high.

- Confused in the implementation and maintenance of measures of quality control to ensure products meet or exceed the standard.

- Meet the criteria of quality and value in every product to the customer.

- Forecast market demand and production planning has not exactly led to production status, excess or deficiency, which causes the waste of resources and increased costs of storage.

Management systems, automated processes, comprehensive privacy solution is removing all the difficulties of manufacturing enterprises at present. Only with management software production process, All-in-one, businesses can capture information about the progress of production, the calculation is workload specific and capture the timely correct the phase error.

- Cost of ERP implementation, how much? The purchase price of the ERP software standard for business

- Roadmap ERP implementation practice & control experience, reduced operating costs

- 9 ERP software downloads best Vietnam criteria in choosing optimal?

- What is ERP System ? Ways of development, necessary for any business?

2. Learn software, production management

2.1 management software what is the production?

Software production management is tools business support optimization of production activities from the stage of planning, materials management, progress tracking for up to control the product quality.

Tool allows the creation process, automatic production system established through the inextricable link between the relevant departments such as accounting, sales, purchase, inventory, human resources, planning and production. All connections in a database single comprehensive suite for business.

2.2 Vai trò của phần mềm quản lý quy trình sản xuất

Research from LNS Research shows the software application management process can reduce up to 25% off production time through streamlined processes.

Software manufacturing ERP is integrated with many outstanding features to support business optimized and streamlined the entire production process. In addition, management software production process also brings the following benefits:

- Dark streamlined the entire production process: By synthesis, track reports, data in the workflow, the software proposes to remove the step excess to poor performance.

- Balance the load of work: Allocate work in reasonable detail for each equipment, staff, stage production limit overload or lack of jobs.

- Coordination between the parts: Với sự hỗ trợ của phần mềm ERP, tất cả bộ phận trong doanh nghiệp từ kỹ sư, công nhân cho đến khối văn phòng như kế toán, kinh doanh, bán hàng,…đều có thể thể theo dõi quy trình, tình trạng kho hàng, sản xuất, phối hợp trơn tru trên 1 nền tảng duy nhất.

- Reduce the cost of production & operating: Support business considerations and resource distribution, human resources and production equipment, reasonable, minimize the wastage. In addition, the software also has features expected raw material, accurate, allow businesses to optimize costs.

- Improve the quality of products: All products are monitored from the moment of selection of raw materials until finished products, ensure to meet all the quality requirements, and significantly reduced the error rate.

- Sync and data management focus: Data on production planning, inventory, purchasing, shipping, management, product quality, or even finance are synchronized and stored to focus on 1 single platform, avoiding the inconsistent information. This allows all members to have a vision about the situation of production, easily access, manage, and analyze data.

3. Top 5 management software most professional manufacturer

Reference list 5 management tools, best production market.

3.1 management software, manufacturing ERP LV-DX

LV-DX is a management system business overall ability customization flexibility to optimize production activities varied industry from agriculture, interior, food to apparel.

Human resources management LV-DX People

LV-DX People is the solution talent management & Human resources, comprehensive help businesses transition of hr processes traditions are very cumbersome and less effective with the following features:

- Theo dõi, quản lý và thực hiện xuyên suốt các hoạt động tuyển dụng nhân sự lao động phổ thông, công nhân ít tiếp cận công nghệ.

- Quản lý phúc lợi, chấm công – tính lương, BHXH, thuế TNCN chó số lượng nhân công lớn nhanh chóng, đồng loạt, dễ dàng.

- Đánh giá nhân viên minh bạch & công khai thông qua hiệu suất làm việc, sản lượng, thời gian làm việc,…

- Đào tạo trực tuyến, học tập đa phương thức và làm chủ đào tạo bởi hệ thống riêng.

- Enhance the experience of employees, reward – honored anytime, anywhere.

- Convey information throughout and efficiently between departments through the hr Portal.

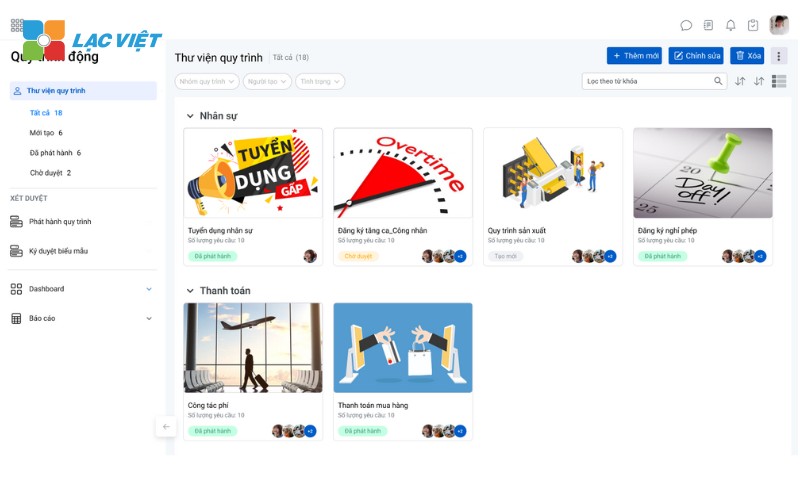

Space plus the number of LV-DX Collaboration

The platform connects people, processes, production, trading and sale of the business on 1 single platform. Provide adequate tools for managers and staff to use to complete the job, including:

- LV-DX Document: Quản lý và lưu trữ thông tin sản phẩm, nguyên vật liệu,…

- LV-DX Task: quản lý tiến độ sản xuất/đơn hàng, theo dõi quá trình vận chuyển và quản lý công việc theo từng bộ phận/xưởng/chuyền.

- LV-DX Dynamic Workflow: Thiết lập và vận hành quy trình mua hàng, tạm ứng, thanh toán; Quy trình đề xuất tuyển dụng, phê duyệt bảng lương; Quy trình phê duyệt chính sách giá, chiết khấu; Quy trình đánh giá chất lượng.

- LV-DX Workspace: Không gian làm việc số cho phép nhân sự giao tiếp, trao đổi và cập những thông báo mới nhất về quy trình sản xuất.

- And many tools to support the management of production.

Financial management accounting LV-DX Accounting

Phân hệ LV-DX Accounting đáp ứng đầy đủ tất cả các yêu cầu của kế toán quản trị, là phân hệ kết nối dữ liệu liên quan đến tài chính của hầu hết các bộ phận trong doanh nghiệp, đặc biệt là bộ phận sản xuất. Giúp tập trung dữ liệu, dễ dàng kiểm soát và quản lý nguồn tiền của doanh nghiệp.

- Access automated reports, books, tax returns,...

- Update the text, circular, latest regulations related to accounting

- Cảnh báo sớm các chỉ tiêu về tài chính giúp doanh nghiệp luôn chủ động và tránh được những rủi ro không đáng có.

- Monitor, analyze, revenue, cost, multi-dimensional: account, department, cost center, category free.

- Provides a full range of financial reports, tax reports according to the rule of Vietnam.

- Ký điện tử/ký số chứng từ nội bộ như tạm ứng thanh toán, phiếu chi, mua sắm nguyên vật liệu, hợp đồng bên ngoài, báo giá đơn hàng,…

Customer administration LV-DX CRM

Manure management system, customer experience, CRM, comprehensive breakthrough revenue growth with the optimal cost, use, multi-platform.

- Connect and synchronize with channels to automatically collect customer information.

- Arranged and divided according to the customer market logic based on the information collected.

- Screening, data analysis, customer into groups according to the objectives.

- Nurture, analyze and track actions and order conversion rates.

- Scheduling automated care based on time intervals via messages, emails, and calls.

Applicable objects

LV-DX fits both large enterprises, small and medium belonging to all the different areas.

3.2 management software production, BRAVO

Bravo nổi bật bởi khả năng bao quát toàn bộ quy trình sản xuất từ quản lý sản xuất, khai báo và quản lý BOM, tính nhu cầu vật tư, cập nhật & theo dõi tiến độ sản xuất, quản lý nhập xuất tồn tại phân xưởng, kiểm soát tiêu hao vật tư,…

Not only stop at that, management software, manufacturing ERP Bravo also allows business statistics output according to the production plan/order production and commissioning process, to test/evaluate the product quality, through which control the quality of each products before distribution to consumers.

Tuy nhiên, điểm hạn chế lớn nhất của Bravo là chỉ cung cấp theo hình thức trọn gói với giá thành khá cao. Điều này gây khó khăn cho các doanh nghiệp nhỏ, đặc biệt là các doanh nghiệp chưa có hệ thống hành chính hoàn chỉnh có mong muốn tiếp cận và triển khai phần mềm.

Feature highlights

- Declaration norm of raw materials for each stage, products or orders.

- Production scheduling based on demand, allows businesses to adjust (add/reduce) production plan if incurred fluctuations.

- Perform production and update the output produced by each stage, production order or production plan.

- Support the calculation and payment of materials and production according to the production orders, or orders, automatic machining.

Restrictions

Nhân sự và đội ngũ công nhân cần được training trước khi sử dụng mới có thể tận dụng hết những tính năng chuyên sâu và đa dạng của hệ thống.

Applicable objects

In accordance with the large-scale enterprises have production models varied, financial resources and strong.

3.3 Công cụ quản lý quy trình sản xuất ERP Faceworks

Management software production Faceworks have the ability to customize in accordance with the requirements of any type of business such as production, wood industry, electronics manufacturing, textile manufacturing, packaging production,...

App allows businesses to manage the details of raw materials, inventory or orders, products,... without need to change any process management.

Feature highlights

- Allows management and storage of diverse kinds of data related to production processes, such as norms of materials, labor, production requirements, production orders, planned execution and data about the stock, such as export, import, inventory, location, commodity,...

- Automatically calculated plan from alerts minimum of inventory.

- Provides reports about the level of productivity each process, progress made, quality products in the form of graphs.

Restrictions

- Nếu không có sự đồng bộ trong cả doanh nghiệp, quá trình sản xuất có thể sẽ bị gián đoạn

- Khó tích hợp với phần mềm thứ 3

Applicable objects

In accordance with the business corporations.

3.4 software process management, production and sales for free VNSolution

System VNSolution is known for its ability to build process self-contained production from when setting up order production needs to plan production plan and calculate the likely supply of raw materials in stock to sales stage.

In addition,VNSolution also features the set norms of raw materials for each stage of production, price calculation, the depreciation rate materials to track the sales process.

In particular, to support the small business approach to software management manufacturing process management software production VNSolution also provides version free use. However, non-restricted quite a lot about the tool works and the ability to store information, so businesses need to consider if you want to use long term.

Feature highlights

- Set of requirements for goods from the source forecast (Forecast) and the order of the customer (Sales Order) to create demand for goods need to produce at certain times.

- Create the production orders based on the number of material goods need production.

- Supports calculate requirements for materials based on the production plan.

Restrictions

- Chỉ cung cấp những tính năng cơ bản, phù hợp với các doanh nghiệp quy mô nhỏ. Đối với doanh nghiệp lớn có nhiều công đoạn và khối lượng hàng hóa lớn, việc sử dụng phần mềm miễn phí có thể gây ra nhiều bất cập.

- Khả năng bảo mật thấp

Applicable objects

Suitable with all types of businesses.

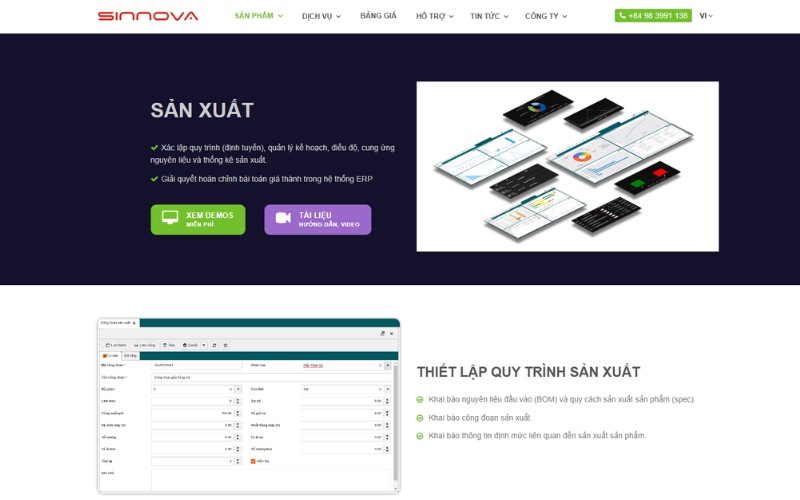

3.5 Phần mềm quản lý sản xuất tổng thể Sinnova

However, as a software process management overall, Sinnova can still make a good role management production through the established process (routing), management planning, dispatching, supply of raw materials and production statistics.

Besides, the software Sinnova also business support status tracking, inventory overview, from the arrangement of space, equipment and machinery to process import – export goods and the management of inventory.

Feature highlights

- Supports automatic scheduling of production, plans to use the machine, resources, raw materials according to the production process.

- Show production planning overview and details on each product visually through the gantt chart.

- Support allocation, production planning detailed stages, according to the date and control of stock produced according to the requirement of supply of raw materials.

- Track details output according to each day work, shift work, stage, production orders.

Restrictions

Giao diện khó sử dụng đối với những đối tượng người dùng không am hiểu công nghệ.

- What is ERP? Benefits, the solution for the problem of managing discrete, less effective?

- 5 The company offers ERP software prestigious professional market

- Introduction software lacviet ERP management intensive treatment for DN Vietnamese

- Consultant ERP deployment: 70% of the projects in trouble, where is the right direction?

4. Selection criteria management software manufacturing standard

Full features responsive production process

Phần mềm quản lý sản xuất cần đáp ứng đầy đủ các yêu cầu quản lý quy trình và lập kế hoạch sản xuất, quản lý nguyên vật liệu, thành phẩm, quản lý kho hàng, quản lý chất lượng, theo dõi tiến độ và báo cáo tiến độ sản xuất.

The ability to integrate multi-platform

To create favorable conditions for the connected devices, IoT, artificial intelligence AI, software management...in the task of process optimization and data storage, production focus, management software, manufacturing ERP need to have the ability to integrate multi-platform.

Or business can refer to the software solutions, business management overall has integrated management, production, process, sales, financial – accounting as LV-DX to settle any problem integration.

Interface optimized user experience

The nature of work produced, including many position different from the leadership, management to staff construction should be designed software should be optimized so anyone can use effectively.

Customizable flexible processes according to specific production

Depending on each industry manufacturing, business will have different needs in establishing operating procedures.

For example, the textile industry requires focus on management in detail each stage of production such as cutting, sewing, finishing products and quality control. Also for the food industry, you need to closely monitor food safety, traceability of raw materials and process management preservation.

Điều này đòi hỏi một phần mềm quản lý quy trình sản xuất có thể tùy biến linh hoạt quy trình để đáp ứng được tất cả lĩnh vực.

Costs in line with business budget

Business should consider the following expenses: deployment, training, maintenance, and upgrade management system, production process, to find the most suitable option.

Because of the nature of complex manufacturing processes like effective, optimum cost, it requires to have the help of a support tool automatically. By considering a thorough selection criteria and 5 software production management comprehensive Lac offers, business process management professional production, cost savings and improve the quality of products/services.

CONTACT INFORMATION:

- Lac Viet Computing Corporation

- Hotline: 0901 555 063 | (+84.28) 3842 3333

- Email: info@lacviet.vn – Website: https://lacviet.vn

- Headquarters: 23 Nguyen Thi Huynh, P. 8, Q. Phu Nhuan, Ho Chi Minh city