Prior to the development exceeds the turn of digital technology, machinery and equipment played a key role in all activities of the business, from production, operation to manage. However, if it is not maintenance, periodic maintenance, these devices can become “points of congestion”, interrupting the process, increase costs, and directly affect profits.

According to research from Deloitte (2023), the business plan effective maintenance can reduce up to 40% of the cost of equipment repair and increased their lifespan by up to 30%. Shows, done right process maintenance machinery and equipment not only is the element to ensure high efficient operation but also the competitive strategy long-term.

In this article Lac Viet Computing will analyze in detail the maintenance process, the important note and practical benefits when business properly applied, or use of the service, professional maintenance.

1. Maintenance machinery and equipment is what?

Maintenance (Maintenance) and maintenance (Servicing) is the engineering activities are performed in order to maintain active status, the performance of machinery and equipment.

- Maintenance: Is the process of inspection, repair and replace the components as necessary to ensure the machinery is always stable operation.

- Maintenance: Is the routine activities such as cleaning, inspection, oil, weight adjusted to keep the device in the best condition.

Today, businesses often applied three forms of major maintenance:

- Preventive maintenance (Preventive Maintenance): scheduling periodic checks to detect early signs of failure.

- Maintenance corrective (Corrective Maintenance): Handling and repair when the device encountered unexpected incident.

- Predictive maintenance (Predictive Maintenance): Use technology, such as sensors, IoT, AI to predict equipment failures based on commissioning data.

Predictive maintenance is becoming a trend thanks to its ability to optimize costs and enhance operational efficiency. A typical example is the application intelligent sensor fault prediction ago from 3 to 6 months, bring huge benefits for the business.

2. The importance of maintenance machinery and equipment in the business

- Increase equipment life and reduce repair costs

Periodic maintenance helps early detection of technical problems and prevent damage serious. Instead of having to replace the entire system, the replacement components in time will significantly reduce the cost. A study by PwC (2024) indicate that proactive maintenance can save up to 50% of the cost of repair compared to the fix after the device to malfunction.

- Ensure the performance, limit interruptions

When the machine works smoothly, work productivity of the business will be maintained stable. The disruptions due to equipment failure not only cause financial loss but also reduces the credibility of the business for customers and partners.

- Comply with the safety standards and environmental protection

A system of machinery operating efficiency will ensure standards occupational safety and minimize the risk of accidents. At the same time, the regular maintenance also contribute to reduce emissions and save energy consumption.

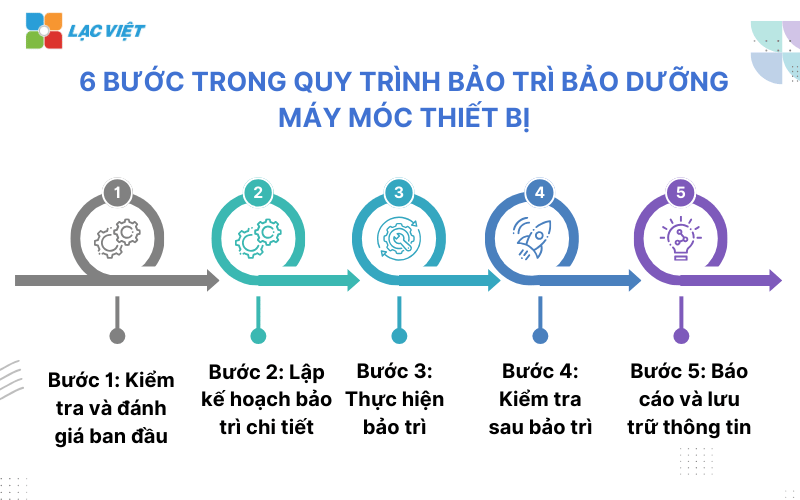

3. Detail the steps in the maintenance process maintenance machinery and equipment

A process maintenance machinery and equipment standards should be built based on the following factors:

- Check list (Checklist): Includes the steps of testing required for each type of device. For example: check the temperature, vibration, energy consumption of machinery.

- Plan states: Determine the frequency of maintenance for each equipment based on the level of use, usually weekly, monthly or quarterly.

- Technician team: Ensure the team are highly professional, well-trained and knowledgeable specific device.

- Tools and material support: Including the software maintenance management (CMMS), instructions for use, and the measurement equipment modern.

Step 1: Check and initial assessment

Objective: to assess the overall condition of the equipment before starting maintenance.

The main job:

- Record the current status through reports or management software.

- Collect information from the sensors or IoT system if it is integrated.

- Assess the level of damage, wear and tear of the components.

Step 2: plan maintenance details

Objective: to Identify the maintenance activities need to perform and time-specific.

The main job:

- Classification of equipment according to the level of priority (e.g., critical equipment, support equipment).

- List maintenance work, and arrange the order of execution.

- Allocate staffing resources needed.

Step 3: perform maintenance

Objective: to conduct maintenance according to the plan outlined.

The main job:

- Hygiene, cleaning the parts, dirt, and grease.

- Replace the components is worn out or damaged.

- Lubricate the moving parts to reduce friction.

- Check and update controller software (if available).

Step 4: Check after maintenance

Goal: Ensure device stable operation after maintenance.

The main job:

- Check out the performance of the device.

- Measure and record the specifications.

- Perform a test run to detect the errors that remain.

Step 5: reporting and storage of information

Objective: to Record the whole process of maintenance to reference and track in the future.

The main job:

- Set up a detailed report of the work already done, parts replaced.

- Updated maintenance schedule next on the management system.

- Suggest improvements if necessary.

4. The important note when performing maintenance procedures maintenance machinery and equipment

4.1. Choose maintenance team match

Technicians: If the business has a team of technicians, need to ensure they are trained and have in-depth expertise about each type of machinery.

Hire maintenance services outside: For business do not have a team of specialized units provide maintenance service professional is a reasonable option. When to outsource, be preferred units prestigious, many years of experience and a clear commitment to quality.

4.2. Use support tool maintenance modern

Software maintenance management (CMMS): Help plan, track, and manage the entire process maintenance. The popular software such as UpKeep, Fiix, or IBM Maximo offer an intuitive interface and maximum support for business.

IoT devices: sensors and IoT devices can provide real-time data, help in early detection of problems performance machinery.

4.3. Store and manage maintenance information

Businesses need to create the habit of taking notes and storing information about each maintenance, including:

- The error was discovered and remedied.

- Components were replaced and the expected time needed replaced next.

- The parameters measure the performance before and after the maintenance.

This information will help build your database is important for the maintenance and predict failure.

4.4. Ensure compliance with safety standards

Before performing maintenance, need to perform the following steps:

- Disconnect the power supply and ensure there is no source of energy to connect with the device.

- Provides complete tools personal protective (PPE) for the team.

- Use the dedicated tool instead of the tool temporarily to avoid damage add.

Process maintenance machinery and equipment not only is an important part in the operation, but also play a decisive role to the efficiency and sustainability of the business. A maintenance procedure to standardize not only help minimize the risk of damage, cost optimization, but also create a platform for business to grow steadily.

Businesses need to focus on building or selecting maintenance services suitable to apply modern technology to effectively manage and comply with strict safety standards. With the right investment level in maintenance, business not only save costs but also enhance the ability to compete in the long term.

If you need detailed advice or search maintenance service professionaldon't hesitate to contact us Vietnam to be the best support.