In all manufacturing enterprises, trade or retail inventory always occupy a large proportion in liquid assets. However, many businesses still managed inventory a way of feeling leads to the condition of goods stagnant, losses or vice versa is a deficiency, interruption of production leads to lost business opportunities.

In the context of operating costs increasing while the market demand fluctuates constantly, inventory management no longer is the task single of parts warehouse, which become strategic elements in the value chain business.

This article Lac Viet will help you understand the management of inventory, what is the reason why businesses need to optimize this operation, along with the method/tool to manage inventory effectively, especially the modern solutions technology applications such as LV Financial AI Agent to help in controlling and analyzing inventory real time.

1. Management what is inventory?

Inventory management is the process of monitoring, control and optimize the entire activities related to the import, export, – storage of goods in the business. The main objective is to ensure the number of inventory at the right level – enough to serve the needs of sales or production, but no excess waste.

To visualize simple management, inventory like you “keep the refrigerator always just enough food” – not teen but not to excess, causing broken. In business, this is through keeping track of inventory for each item, control the time of ordering, specify the long planning additional shipment handling slow-moving.

The core objective of inventory management include:

- Balance between market demand and internal resources;

- Optimize the cost of warehousing operation;

- Minimize false data inventory;

- Support financial decisions, based on real data.

A business, although have good products to now, but if not, better control inventory, easy to fall into the shortage of raw materials, excess merchandise, even wasting asset due to expired, obsolete or damaged. Inventory management efficiency to help businesses:

- Proactive production planning – business;

- Minimize the costs of storage, loss of goods;

- Limiting losses due to deviations between the books/practice;

- Increase speed to meet orders, enhancing customer experience.

- 10+ ERP Management Accounting Software with AI Compliant with Circular 99/2025 for Vietnamese Businesses

- 9 Accounting Software online cheap cost reduction for small and medium ENTERPRISES

- Inventory inventory done when? Regulation process & optimization methods

- Download report template inventory excel file/ggsheet ADEQUATE for the business

2. Why inventory management?

Inventory not only is the liquid assets on the balance sheet. There is also a “lever” or “burden” finance depends on how the business control. Admin inventory is good platform helps businesses ensure continuous production, reduce unnecessary costs, optimize cash flow, enhance operational efficiency throughout the system. Here are 5 reasons core reason why inventory management is a mandatory task, can't see the light.

2.1. Ensure continuous production avoid disruption because of the lack of raw materials

A production line, although modern where also can't operate if the lack of raw materials at the right time. Just missing a small detail like buttons, fabrics or packaging packaging, the entire production plan may have to pause, pull in damage of the machine and the progress of the delivery.

Inventory management tightly to help businesses maintain the supply of raw materials, stability, limit depends on external factors such as market fluctuations or delays from the vendors.

A sewing workshop, uniform, put the production schedule for 5,000 shirt work but come on Monday, then detection teen zippers do not be imported. The no-warning minimum of inventory, causing production delayed 3 days, affected the progress of the delivery reputation with customers.

2.2. Optimal costs of storage, maintenance and depreciation of assets

Store inventory is not free. Inventory as much as the cost incurred as big: from the cost of premises, staff, supplies, equipment storage to the natural shrinkage and the opportunity cost of the capital is “detained” in stock.

According to statistics of the World Bank, the cost of storage accounts for about 25-30% of the total logistics cost. This is the proportion of very large, especially business has system wide distribution or production on a seasonal basis.

When businesses better control the number of input – output – inventory and rotation of goods fixed cost reduction, cash flow is freed, real profit increased in a sustainable way.

2.3. Timely detection of the slow rotation or long backlog

Not inventory always useful. Some items may lie in warehouses for many months, which is the go – this leads to the risk:

- Damaged or expired (especially with consumer goods, food products, pharmaceutical products)

- Outdated template code, technology (electronics, fashion, accessories)

- Increase storage costs, and difficult to sell liquidation

Illustrative example: A distribution company electrical equipment hold back the more than 1,000 socket of the last 12 months without new orders. When entering a tranche of new and old models to sell off 60% discount, loss of profit, wasted capital.

Business better control inventory will easily recognize the slow rotation, from which planned promotions, discounts, internal or stop extra income to avoid double holes.

2.4. Optimize cash flow thanks to the balanced inventory – order logical

Inventory not sold, but have spent the cost of buying into. If the inventory is too large compared with the speed of consumption, the capital has become “dead capital” – that business is not enough resources to invest in other activities.

Conversely, if inventory too little risk, a lack of goods will appear, affecting sales, satisfaction of customers.

Solution: set inventory levels, minimum – maximum, combined with data analysis, sales, consumption history to order a reasonable balance between cost and ability to serve the market.

Optimal inventory means freeing up cash flow, to help businesses have the resources, invest in marketing, technology, or product improvement.

2.5. Support analysis of business performance according to products, orders, distribution channel

Data inventory when managed properly can become a source of valuable information for decision-making:

- Any product consumption, fast turnaround?

- Group of any inventory long, need to adjust strategy?

- Distribution channels the most efficient freight movement?

When data integration, inventory system, accounting software, sales or management software, business managers can create the dashboard, visual analytics, support, evaluate the effectiveness of the multi-dimensional.

From an inventory report, businesses can re-structure, product portfolio, reorientation sales strategy, and optimal operating costs.

3. The method of inventory management efficient today

In the context of competition increasing, the selection of the right method of inventory management not only helps business reduce costs of storage, limiting the losses but also improve operational efficiency, the ability to meet the market. Below are the popular method is widely applied in many businesses.

3.1 Methods of FIFO, LIFO, JIT – briefly Explain, easy to understand

- FIFO (First In – First Out): imports ago is ago. In accordance with industry are perishable goods or degradation such as food, pharmaceutical, cosmetics.

→ Benefits: Reduce the risk goods expire, ensuring quality when delivered to customers. - LIFO (Last In – First Out): enter the following are prerendered. Often used in the environment of price fluctuations, or product doesn't distinguish in batches.

→ Benefits: can reflect the cost of the most recent market prices in the financial statements, in accordance with the manufacturing enterprise. - JIT (Just In Time): enter Only when need production, when there is. System requirements correct management, supply chain stability.

→ Benefits: minimize inventory, save storage costs, increase rotation goods.

3.2 ABC analysis – Focus on the group of a key

ABC method divides inventory into 3 groups based on values contribute to the total revenue or profit:

- Group A: 20% of the volume but accounts for about 70-80% of the value of inventory. Need to manage, update inventory regularly.

- Group B: Accounting for 30% amount, approximately 15-25% of the value.

- Group C: 50% of the volume but accounted for only 5-10% of the value.

→ Benefits: optimal resource management by focusing on products that have great influence on financial performance, avoid spreading resources unnecessarily.

3.3 Apply financial ratios: Inventory Turnover, DSI

- Inventory Turnover (inventory turnover) = cost of goods sold / inventory average

→ Only the higher the number, proof of goods to be consumed fast, high efficiency. - DSI (Days Sales of Inventory) = (inventory average / cost of sales) × 365

→ Only the lower the number the business, the less tie up funds in inventory.

→ Benefits: to Help businesses evaluate the effectiveness and inventory management over time, since then adjust the plan purchase – production compliance, reduce risk, excess inventory.

3.4 inventory periodically combines data software

Perform warehouse inventory periodic (month, quarter, year) in order to collate real-world data with the data system. When combined with warehouse management software (for example: the software can integrate with LV Financial AI Agent), businesses can:

- Automatic alerts arbitrage inventory.

- Analyze the causes shrinkage.

- Proposed adjustment of import – export logical.

→ Benefits: enhance transparency in governance, limiting fraud losses goods.

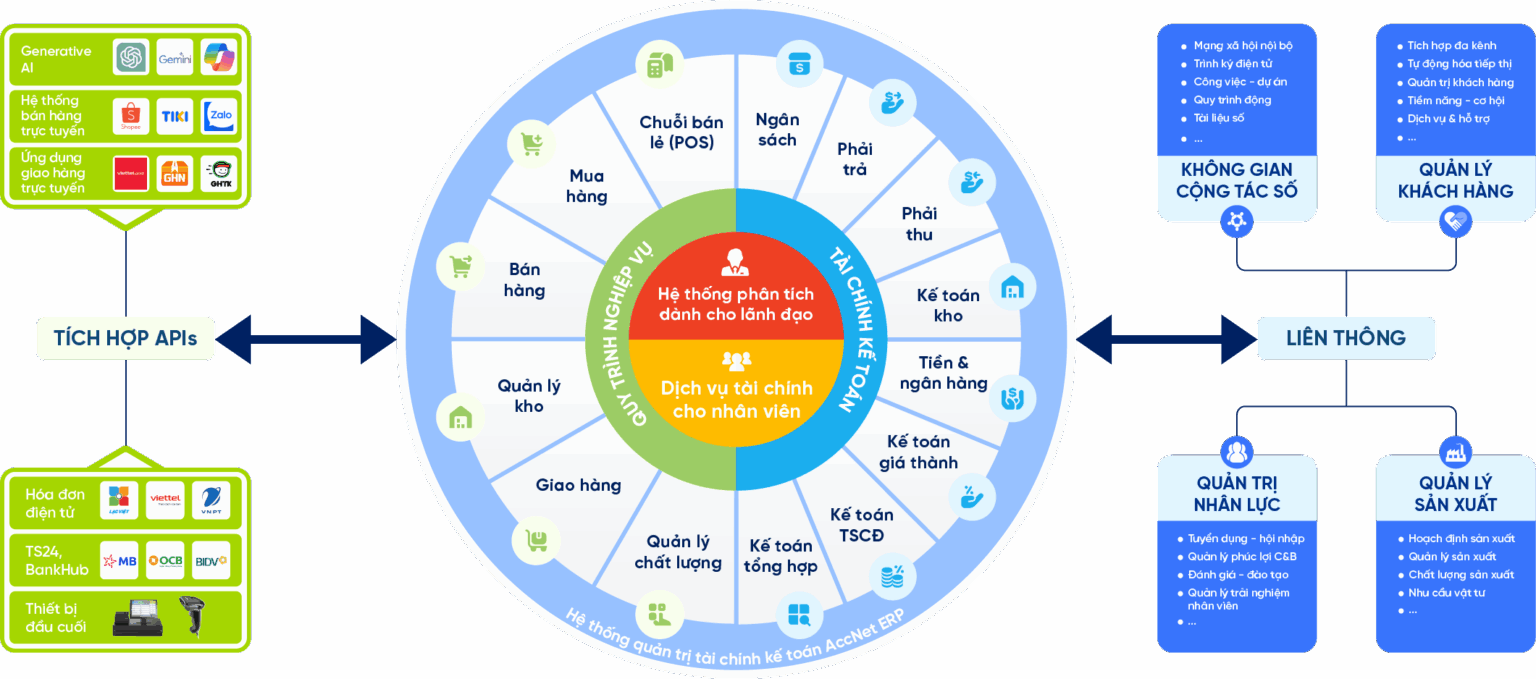

ACCOUNTING SOLUTIONS ACCNET ERP INTEGRATED AI AUTOMATE ALL BUSINESS

AccNet ERP is a software solution financial accounting integrated in the management system, comprehensive enterprise, which is developed by Lac Viet corporation. Difference highlights of AccNet ERP is the app artificial intelligence (AI) in many accounting process to help businesses:

- Automation of accounting and classified documents.

- Improving the accuracy in data control.

- Shorten processing time business accounting – financial.

Thanks to that, AccNet ERP not only is support tool but also a “smart assistant” with the business in financial management transparent effect.

Feature highlights:

✔️ Automatic accounting vouchers, collate public debt thanks to AI.

✔️ Manage your finance – accounting multi-branch, multi-subsidiary.

✔️ Financial statements consolidated standards of Vietnam & international (VAS, IFRS).

✔️ Cash flow management, budgeting, forecasting the exact cost.

✔️ Connect with the manure management system, hr, production, sales to sync data.

✔️ Integration of AI in data analysis, risk warning and proposed optimal scheme.

TYPICAL CUSTOMERS ARE DEPLOYING ACCNET ERP

- Nitto Denko – control production costs thanks to the application of accounting costing: Nitto Denko has chosen solution AccNet ERP to deploy the system accounting calculating cost ofhelp business control costs more effectively in the production process. After a period of use, company, highly effective, practical system that brings, as well as the degree of stability superior to other software in the market.

- ANTESCO – restructuring process works with management accounting operation: At ANTESCO, our team of consultants and deployment of AccNetERP has collaborated closely with the business in the first phase, reset the standard process and construction work-flow related departments throughout. The solution has helped ANTESCO significantly improve management capabilities, operating in a synchronized way and versatile

- Khatoco – expansion pack solution AccNetC after the successful implementation of original: Lac Viet has successfully deployed package solution AccNetC for trade co., LTD Khatoco in Nha Trang, according to the agreement signed on 29/07/2014. After the system is first put into operation efficiency, Khatoco intends to continue cooperation and expand the distribution finance – accounting and retail management with AccNetC, expressing the deep trust in implementation capacity and quality of service from Lac Viet.

SIGN UP TO RECEIVE DEMO NOW

INTEGRATED AI ACCELERATION CONVERTER OF ACCOUNTING

AI in AccNet ERP't just stop at automate data entry, but also:

- Identification & classification certificate from smart: AI scan, read & sort invoice, voucher, receipt, limit errors due to input manually.

- Financial forecasting & budget: the system uses algorithms machine learning to forecast cost, revenue, business support decision fast.

- Warning risk accounting: AI to detect abnormalities in the book, from which timely warning of false or fraud risks.

- Reports assistant smart: AI suggested report template, automatic data aggregation support, leadership, financial analysis instant.

BUSINESS IS WHAT WHEN IMPLEMENTING ACCOUNTING SOFTWARE LAC VIET?

- Experience more than 30 years develop software solutions business management in Vietnam.

- Ecosystem of comprehensive: AccNet ERP easily connect with other solutions of Lac Viet (HRM, Workflow, Portal...).

- Advanced technology: Integrated AI support, cloud & on-premise flexible.

- Services dedicated support: A team of knowledgeable professionals with accounting – finance in Vietnam, companion throughout the deployment.

- Trust from thousands of customers in many areas: finance, banking, manufacturing, trade, services.

See details, feature & get FREE Demo

CONTACT INFORMATION:

- Hotline: 0901 555 063

- Email: accnet@lacviet.com.vn | Website: https://accnet.vn/

- Office address: 23 Nguyen Thi Huynh, Phu Nhuan, ho chi minh CITY.CITY

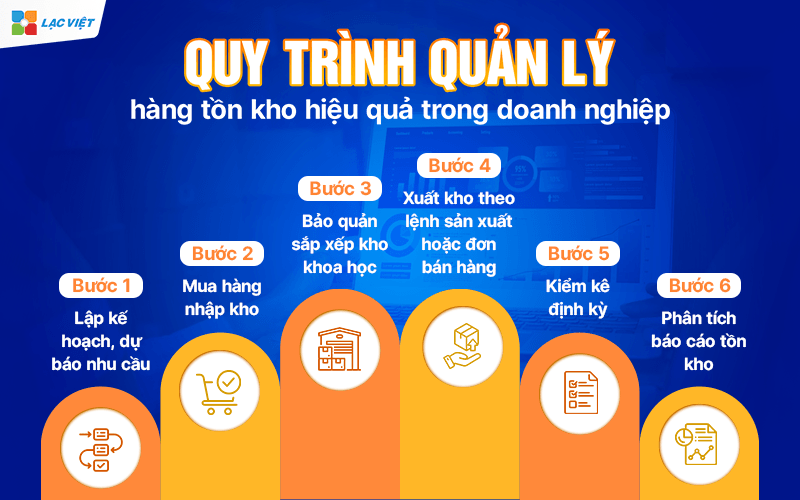

4. Process of inventory management efficient in business

Admin inventory is an important link in the chain operated business, directly affect the cost, the ability to meet orders and financial performance. A process, inventory management, it not only helps businesses get top quality out there, but also supports the correct decision on import – export – goods store.

Process of inventory management efficient in business

Step 1. Planning, demand forecasting

This is the first step play a background role. Forecast the demand for the commodity must be based on the realistic elements such as:

- Sales data of the previous period

- Consumer trends according to seasons

- Marketing campaigns are deployed

- Inventory levels, minimum required to maintain (safety stock)

If the forecast is not accurate, the business may fall into shortage of goods caused a loss menu or inventory too much, wasting storage costs.

For example, A business selling drinks need to forecast increased demand in summer. If the prediction is correct, they can actively put material goods soon with the best price, limit buy folding at high prices.

Step 2. Purchase warehousing

Once you have identified the number of required purchased parts purchase will execute order process:

- Selection of suitable suppliers (price – quality – delivery time)

- Order tracking delivery schedule

- When receiving goods, parts warehouse need tally – for projectors – assess the quality of the goods before to enter into the system

Good management stitching warehousing help ensure information accuracy, avoid errors extends to the following steps.

Step 3. Preserved arrange warehouse science

Stock should not be where the “keep temporary”, which is where managed assets have value. The sort of goods should be based on:

- Type of goods: raw materials, semi-finished products, finished products

- Physical properties: fragile, perishable, need temperature conditions...

- Degree rotation: stores selling should be placed near the door to convenient cumshot

In addition, it should use the method of inventory management efficiency, such as:

- FIFO (First In First Out): export in order to enter

- FEFO (First Expired First Out): priority shipment has a shelf life soon

This helps to avoid wastage due to delinquent or damaged, especially with the industry of food products, pharmaceutical products.

Step 4. Export warehouse according to production orders or sales orders

Every activity warehousing need to have stock from clear and be updated on the system to avoid false inventory.

- Production: production of materials according to the level of each order

- Sales: export to-order approved

The recognition of the right time will help businesses track the value of goods consumed, support calculate the price of capital, real profits.

Step 5. Inventory periodically

Even though there was system software, but the actual inventory is still very necessary to:

- Determine the difference between books and reality

- Detection of loss, damage, error operation

- Check compliance with the import – export – storage

Businesses can choose inventory periodic monthly, quarterly, or according to each storage area. The inventory should be carried out plan, have record, the person responsible.

Step 6. Analyze inventory report

The final step in the process of inventory management, but strategic. After obtaining accurate data, business needs analysis:

- Inventory turnover ratio (as high as possible – present rate of consumption, fast)

- The rate of inventory compared to revenue (helps control inventory costs reasonable)

- The number of days of inventory average (said goods and how long does it take to sell)

5. Regulation inventory management business needs building

One of the factors that determine the stability effective in the management of inventory is the set regulation clear internal consistency capable of practical application. Regulation not only is the text of governance, administrative that should be the tool operating practice to help businesses control the flow of goods, data, inventory transparency can access the check is. Below is the structure of the core business should prioritize building in this regulation.

5.1. The principles required in regulation

Authorized import – export – clear inventory: The separation of functions between the stitches enter the warehouse, production, warehouse, inventory, and approved not only help reduce your risk of errors, but also limit the fraud. For example:

- Staff warehouse import not export warehouse

- Mature, warehouse inspection of physics, but not self record

- Parts inventory independently operated daily

Help increase transparency, decrease depends on the individual, increasing the ability to detect false data.

Set the inventory levels, minimum – maximum: This tool is important for businesses to know when further input or stop input. The level should be set for each item, according to the group daily, seasonal or consumer demand.

For example: A company produced beverage regulation inventory the minimum is 1.5 tons. When inventory hits this level, the system will alert to purchase parts to prepare the next order.

Balancing between costs of storage and the ability to meet orders avoid missing goods disruption or daily balance, causing “bury capital”.

Specified time inventory periodically: monthly, quarterly, unscheduled: Businesses need to set calendar inventory periodic and unscheduled to compare actual figures with the book:

- Inventory periodically: the End of the month or end of quarter

- Inventory alternate: According to the group per week to reduce the volume once

- Inventory unscheduled: When in doubt loss, abnormal fluctuations

Benefits: timely detection of deviations, avoid the situation last year, “balance again from the beginning” cause of financial turmoil.

Apply rules of stock clear: FIFO, LIFO or in batches production

- FIFO (first-ago): for row perishable, limited use

- LIFO (income after prerendered): can apply temporary with a number of ingredients finance

- According to the number of plots: important in the industry have traceability as pharmaceutical, food, medical equipment

Benefits: minimize loss and management according to use time more efficiently.

Process coordination between accounting – inventory – production – purchase order

The regulation should clearly describe how the department coordinated as:

- Set up order production → requires export warehouse

- Purchase → set stock earnings

- Window warehouse → update accounting data

- Inventory report → report financing

Benefits: synchronize data, avoid entering wrong – export-wrong – reflection wrong price of capital.

5.2. The form should standardize

Businesses need to design a form standard to all actions are grounded clear and consistent.

- Import – export – shipping – inventory: specify the item code, item name, unit, number, stock, who made the browser. Electronic signature or encryption if user software

- Table general inventory: According to the item group, and each storage area. There are number of materials, states, arising in the period, survive the end of the period

- Table inventory alert: auto-alert when items close to hitting the minimum. Report inventory longer than X days

Benefits: Standardization helps users easy to make – leadership easy control – system automation.

5.3. Connect statutes with system software

Regulation only really effective when it is transformed into operation on the system software, to avoid “writing a place – operate a path”.

- Synchronous regulation with warehouse management software: Setting inventory levels in the system, assign, by role, responsibility, set up calendar inventory automatic recurring reminder

- Process automation browser votes, record deals: Coupons import/export created from orders or internal requirements, which is approved on software, system updates window warehouse and accounting

- Enhanced transparency – access: All the save operation stain according to the account, the time. Easily check off any service when there are deviations

Benefits: Helps regulation does not only lie on paper that became the operating mechanism reality – exactly – does not depend on memory or personal experience.

6. The real state enterprises often encounter in inventory management

Inventory management not only is the recorded number of goods import/export. In fact, many businesses – especially the small and medium enterprises are experiencing no less risky obstacles that keep operating costs, increase efficiency business decline. Here are the typical problems:

Still depends on the Excel craft, easy to mistake lack of updates: The majority small and medium business is still using Excel spreadsheets to track export – import – inventory. Though low-cost, easy to deploy, but this method revealed many disadvantages:

- Data to be overwritten, enter the wrong formula, or lack of consistency between the file

- Not capable of automatic updates when goods move between the warehouse

- Does not support data connection with other parts such as purchasing, accounting, sales

Teen warn the inventory levels, minimum – maximum: Not set keeps track of inventory levels, lead to two extreme scenarios:

- Items missing: None timely delivery customers, interruption of production, loss of orders

- Daily balance: costs, storage, preservation, risk damaged – obsolete

Many businesses only detect incidents when has incurred damage, instead of having early warning system.

Not classifying inventory according to the duration of storage (FIFO/LIFO): No little business has not applied the principles of inventory management such as:

- FIFO (first in – first out): required with perishables, limited use

- LIFO (income after – before): sometimes matching the raw material price increase

Not classified made the long neglected, especially in the industry have the goods in batches, according to the term user or fashion seasonal.

Lack of data connection between the parts: warehouse – buy – sell – production – finance: When the data inventory is not continuity between the departments, the consequences are:

- Purchase parts put excess for not knowing rows longer in stock

- Sales department promise delivered early, but the actual stock availability

- Office of finance and difficult to forecast cash flow do not capture the value of inventory updates

The discrete about this data that businesses lose the ability to make decisions fast, accurate.

- Accounting what is inventory? Business process, accounting, inventory, according to TT, 200 and 133

- 7 Table import inventory excel template excel file full professional

- Report export, import, inventory: How to set any template Excel daily commodity standard

- Admin inventory in logistics how effective most optimal?

7. Application of technology in inventory management modern

Instead of depending solely on manual processes, today many businesses have begun to apply technology to manage inventory accuracy, more cost savings.

7.1 inventory Management in Excel

Advantages:

- Easy to use, suitable with small business.

- No cost software deployment complexity.

- Can set up the sample tables, export – import – survival simple.

Limit:

- Data vulnerable to edit/delete it manually.

- No warning of inventory exceeds the threshold.

- Can't link with the system of sales, accounting and production.

→ Excel match beginning stages but not strong enough to follow the business is scaling.

7.2 inventory Management software, ERP, accounting

Sử dụng phần mềm chuyên dụng như ERP accounting software hoặc quản lý kho giúp:

- Closely connected between the inventory – sales – accounting.

- Recorded data in real time.

- Automatically set inventory report details according to the item group, and each location storage.

- Minimize errors due to manual action.

→ Benefits: Increase accuracy, save personnel and support rapid decision-making.

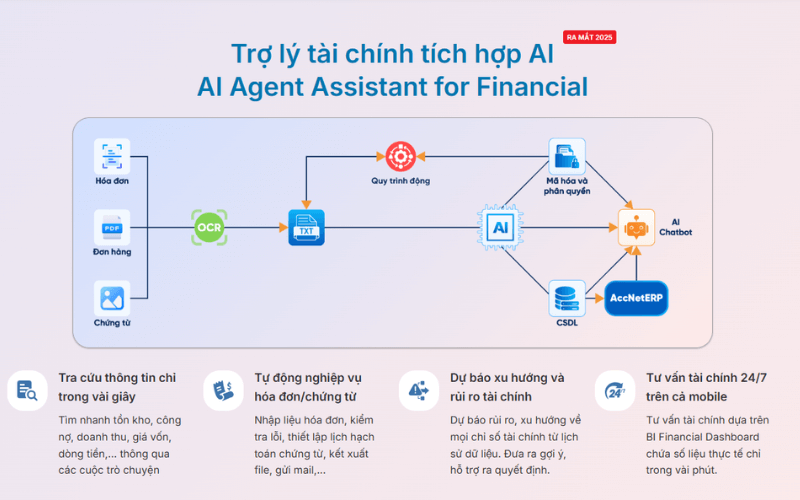

7.3 Solution integrates AI – automated analysis give a warning

A current trend is the integration of AI (artificial intelligence) to inventory management to handle big data, make decisions faster, more efficient.

Solution LV Financial AI Agent – integrated into the software, financial management and inventory of the business – support:

- Volatility analysis inventory in real time.

- Give early warning when the amount of inventory exceeds or lower security level.

- Hint adjusted purchase plan – production based on sales data, cycle, seasonality, inventory old.

- Automatic synthesis report inventory as required by accounting, and business leaders.

Lac Viet Financial AI Agent to solve the “anxieties” of the business

For the accounting department:

- Reduce workload and handle end report states such as summarizing, tax settlement, budgeting.

- Automatically generate reports, cash flow, debt collection, financial statements, details in short time.

For leaders:

- Provide financial picture comprehensive, real-time, to help a decision quickly.

- Support troubleshooting instant on the financial indicators, providing forecast financial strategy without waiting from the related department.

- Warning of financial risks, suggesting solutions to optimize resources.

Financial AI Agent of Lac Viet is not only a tool of financial analysis that is also a smart assistant, help businesses understand management “health” finance in a comprehensive manner. With the possibility of automation, in-depth analysis, update real-time, this is the ideal solution to the Vietnam business process optimization, financial management, strengthen competitive advantage in the market.

SIGN UP CONSULTATION AND DEMO

Inventory management is no longer pure work of the logistics department, which is a core part of strategy to operate effectively optimize cash flow of the business. When the data inventory is managed accurately, continuous updates, tap the right way, the business will be in control costs, avoid risks deficiency or excess goods at the same time quicker response to market demand.

In the context of competition is increasingly fierce, the application of support tools such as warehouse management software is great, especially the solution can integrate artificial intelligence as LV Financial AI Agent will help businesses not only good management of inventory, but also create competitive advantages in the long term.